How 3D Printing in Aluminum Really Works

We’d like to give you an insight into how 3D printing in Aluminum really works. In this blog, we’ll take a look at the technology and inform you about all the details you’ve always wanted to know.

(more…)

Miniature, 3D-Printed City Hall of Antwerp Shows off Every Last Detail

The city hall of Antwerp is one of the city’s architectural crown jewels. Dating back from the 16th century, it hadn’t undergone significant restoration for the last 60 years, and the grand old building was starting to show signs of its age. The municipality of Antwerp has set an ambitious restoration project in motion, which was explained and displayed at Paviljoen Antwerpen Morgen. Held at MAS, the exhibition covered the biggest urban development projects the city has planned for the future. And at center stage was a giant 3D-printed model of the renovated city hall!

(more…)

5 Tips to Make Your 3D Prints Cheaper

Receiving a high-quality print for an affordable price is the number one concern for most 3D printing enthusiasts. So it’s about time to reveal some simple tricks that can reduce your 3D printing costs enormously.

(more…)

Massive 3D-Printed Replica Of A Legendary WWI Ship Makes Waves

Nestled along the coast of Belgium is the mostly open-air Raversyde in Ostend with its bunkers, observation posts, and subterranean corridors. This museum is unique in that it commemorates sites that were instrumental in both world wars: in WWI as a coastal battle and during WWII as the site where Nazi Germany built the Atlantic Wall as a defense. For the museum’s opening weekend of the 2020 season, they prepared a new focal point in the exhibition of the First World War Coastal Battery. The highlight of the exhibit is a massive, highly detailed, 3D-printed model of the Mauretania that carried out different but essential functions during WWI.

(more…)

What Happens If You Upload a 3D Model with ‘Errors’ to Our Site and Place an Order?

Creating an ideal 3D printable model can be intimidating to new users. If you follow this blog closely, you’ve probably heard us advise you about avoiding common 3D modeling errors. That’s why many people ask us: what happens if I place an order, but my file still contains errors?

(more…)

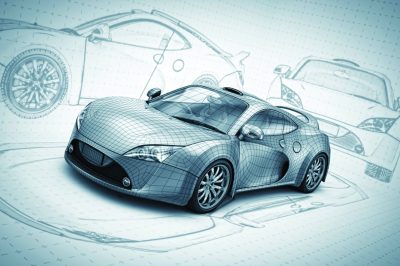

4 Ways Prototyping With 3D Printing Gets Businesses Back On Track

Returning to the office as lockdowns lift first and foremost means keeping your team healthy. Once a concrete safety plan is in place, the next step is to pick up where you left off and bring operations back up to speed. In this post, we’re sharing how 3D printing can help you get product development back on track upon returning to the office.

Due to the coronavirus, changes to the way we worked were sudden. But thanks to the capabilities of rapid prototyping and 3D printing more broadly, your product development timeframe doesn’t need to suffer. Here’s how.

(more…)

Democratizing Prosthetics Through The Power Of 3D Printing

The refinement of prosthetics has been an ongoing challenge since their first creation around the time of ancient Egypt. Although new technological developments have enabled huge improvements to be made, the quest for a prosthetic that can replace the functionality of a missing limb while also being widely available, affordable, and comfortable still eludes even the top design and medical professionals.

(more…)

Art And 3D Printing Come Alive In Amazing Skull Sculpture

With walls as his canvas, renowned Belgian graffiti artist Steve Locatelli is known for his brightly colored murals and work featuring skulls. Although first and foremost a painter, Steve has recently started exploring the medium of sculpture and the use of high-tech industrial tools. His recent work, “SCRATCH 3D,” employed laser cutting to create a wall-mounted piece of intricately crossed metal bars that bridges the gap between painting and traditional stand-alone sculpture. But he wanted to take this a step further and called on designer and illustrator Peter Serruys to help him realize the next iteration – the 3D-printed “SCRATCH 4D.”

(more…)

4 Designs On i.materialise To Help Stop COVID-19 As Lockdowns Lift

Though much of the world is under lockdown due to the coronavirus, some are starting to think of reigning in some measures while still staying safe. The 3D-printing community has been busy during this time developing designs to help the public do just that. From face mask clips to badge holders, here are a few of our favorite items available on i.materialise that were created to protect people in situations where contact with others is unavoidable.

(more…)

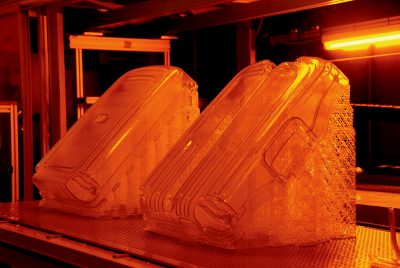

How to Remove Support Structure from 3D Prints

Some 3D printing processes will require what is known as support. Since we cannot print into thin air and the laws of physics and gravity also account for 3D printing, some objects with overhanging parts need support structure. In this blog post you will discover which materials use support structure, what this means for you as a customer, and how you can remove support structure from resin prints yourself.

(more…)