How 3D Printing in Aluminum Really Works

We’d like to give you an insight into how 3D printing in Aluminum really works. In this blog, we’ll take a look at the technology and inform you about all the details you’ve always wanted to know.

The Technology: Direct Metal Laser Sintering (DMLS)

To print your 3D model in Aluminum, we use Direct Metal Laser Sintering technology (or DMLS). DMLS is an extremely advanced manufacturing technology that uses powdered metals as a base. A high-powered laser is used to selectively bind these metal particles together. This is done layer-by-layer, with the machine distributing a new layer of metal (in this case, Aluminum) powder after one layer has been sintered. It’s important to note that support structure is necessary when 3D printing in Aluminum. However, this structure is automatically generated and will later also be manually removed. Once the print is complete, a final heat treatment takes place.

The Material: 3D-Printed Aluminum

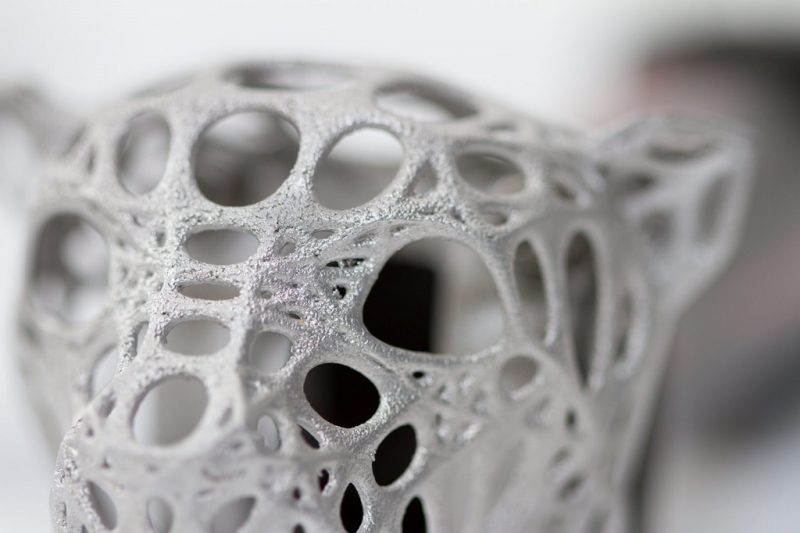

The base used in Aluminum 3D printing is an Aluminum powder sintered together using a high-powered laser. Models printed in Aluminum are very strong, precise, and can handle details of 0.25mm.

Our 3D-printed Aluminum is often used for fully functional parts as well as spare parts, but Aluminum is also very suitable for printing jewelry.

Furthermore, our Aluminum comes in a natural gray finish which looks a little different to the traditional, shiny, milled aluminum – it’s slightly grayer and more matte.

The Design: How to Get a Great Aluminum 3D Print

When designing a 3D model for Aluminum, there are some basic rules, tips, and tricks you will want to take into account:

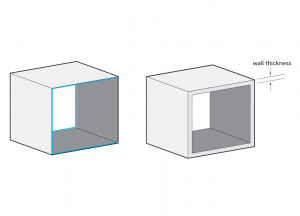

- The minimum wall thickness you should stick to is 1 mm

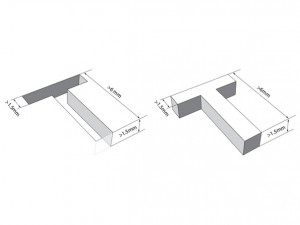

- If you would like to have small details on your print, Aluminum is a good material to do so. DMLS technology allows a very fine level of detail, even as small as 0.25 mm. However, if your details consist of engraved or embossed text, your letters will need a minimum line thickness of 0.4 mm, a minimum height of 0.4 mm, and a minimum depth of 0.15 mm

- When designing your 3D model for Aluminum, you should take a second to think about the geometry of your design. Angular shapes, right angles, and straight lines can look a bit less attractive compared to freeform or organic shapes. It is better to have steep angles of more than 35° because they are likely to have better, smoother surfaces. Angles measuring less than 35° and overhanging structures tend to have poorer surface quality. The ideal shape when using DMLS is that of a mesh. These shapes are easy to design and deliver the best results

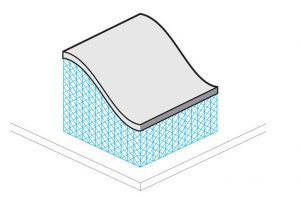

- With DMLS technology, a high-powered laser sinters Aluminum powder together to form your print. However, support structures are necessary to keep your model rigid during printing and to prevent internal stress and deformations. If we would not use support structures, walls or overhangs with angles below 40° would be in danger of collapsing during the printing process. These structures are automatically generated and 3D printed in Aluminum. Afterward, they are removed manually and, finally, the part is sandblasted for a smooth finish

- If you would like to design holes in your model, you should take into account a minimum diameter of 1 mm. Otherwise, powder will get stuck inside the print and we won’t be able to remove it

- And finally, nested objects (objects floating within another object), hinged, and interlinking parts (for example, chains), cannot be made using the technology of DMLS due to the necessity of support structures

If you would like to learn more about 3D-printed Aluminum, you can find all the information concerning the material, colors and finishes, design guides, and technical specifications here. If you already have a 3D model and would like to print it in Aluminum or in one of our 100+ other materials and finishes, simply upload your file, choose your material, and see the price in seconds.

Recommended Articles

No related posts.