3D Printing Business Ideas: 3 Essential Tips

Learn how to turn a 3D printing business idea into reality: start with an idea that adds value, keep your costs low, and learn from successful 3D printing start-ups. Read on to see which 3D printing business models generate profit.

(more…)

3D Printing Design Tips From Professional Designers

Designing for 3D printing is not always an easy task. While creativity has no limits when you’ve mastered the right 3D design software, optimizing designs for 3D printing can be tricky for beginners.

That’s why we wanted to offer you a compilation of the best design tips for 3D printing given by those who know it well: professional 3D designers. What does their 3D design process look like? Which 3D printing software do they use? Which tips would they give to new 3D designers? Read on to discover their thoughts!

(more…)

3D-Printed Action Figures: How To Make Your Own Action Figure

3D printing has impacted all kinds of objects — even action figures. Big brands like DC Comics have even signed deals with 3D printing companies to print some of their figurines. But since 3D printing is all about customization, it is also the perfect technology to create your own action figure. Here’s how it’s done!

(more…)

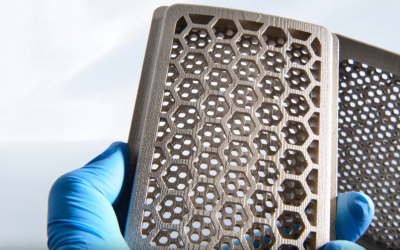

3D Printing In Steel: How To Get The Perfect Steel 3D Print

Being able to get a print in real, solid steel is one of the coolest things 3D printing has to offer. However, we get quite a few questions about the look and feel of this material. In this article, we want to explain to you how steel 3D printing works, what color and finishing options you can choose from, and how you need to prepare your 3D design to get a great steel print!

(more…)

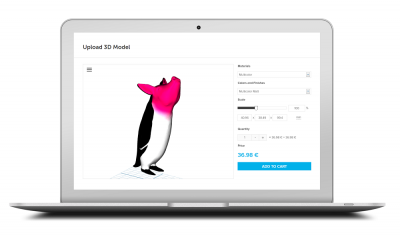

I Uploaded My 3D Model — Now What?

Ever wonder what happens to your file after it’s been uploaded to i.materialise? In this post, we’ll walk you through the steps your models go through, from automated and manual checks to file preparation, production, and cleaning. We’ll also dive into what happens from the moment you click “order” until your 3D print arrives on your doorstep.

(more…)

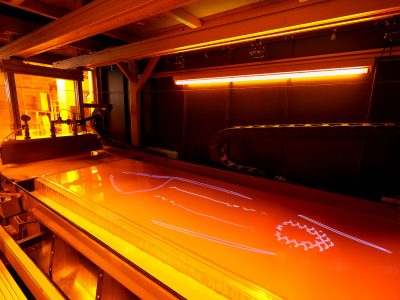

The Most Important 3D Printing Technologies And Materials You Need To Know

If you believe that all 3D printers use filaments and if terms like Stereolithography, Laser Sintering, and PolyJet Printing cause you headaches, then this blog post is for you. Here, we share an overview of the essential 3D printing technologies and 3D printing materials that are currently used on an industrial level.

(more…)

Solving a Real 3D “Puzzle”

With decades of experience in puzzle making, Oskar van Deventer has designed some of the most challenging and intricate 3D puzzles seen on i.materialise. He’ll use anything from computer-aided design programs to nail polish to make his vision come to life. He walked us through his design process and gave insights into some of his upcoming projects.

(more…)

5 Mistakes To Avoid When Designing A 3D Model For 3D Printing

We know that modeling for 3D printing can be confusing: in 3D modeling, as in 3D printing, there is no one-size-fits-all approach. We all use different software, print in different materials, and not only use different printers, but also different printing technologies. So it’s perfectly normal to feel lost and it can sometimes seem difficult to design a perfect 3D model for 3D printing.

(more…)

Meet The Polyamides Of i.materialise

Polyamide is one of manufacturing’s most popular families of materials, and it goes by many names. So, what sets each option apart, and which one is the best choice for your project? Let’s take a closer look.

(more…)

3D Printing For Beginners: A Dictionary

3D printing is fascinating and intricate at the same time, and understanding every 3D printing concept can be overwhelming when you are just starting out. Learning the different materials and technologies gets even more complicated with the often complex 3D printing terminology.

(more…)