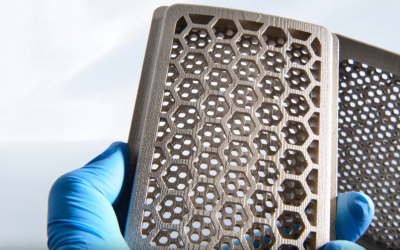

3D Printing In Steel: How To Get The Perfect Steel 3D Print

Being able to get a print in real, solid steel is one of the coolest things 3D printing has to offer. However, we get quite a few questions about the look and feel of this material. In this article, we want to explain to you how steel 3D printing works, what color and finishing options you can choose from, and how you need to prepare your 3D design to get a great steel print!

(more…)

Meet The Polyamides Of i.materialise

Polyamide is one of manufacturing’s most popular families of materials, and it goes by many names. So, what sets each option apart, and which one is the best choice for your project? Let’s take a closer look.

(more…)

Which 3D-Printed Resin Is Right For You?

Are you thinking about 3D printing in resin? Would you like to know more about the technology behind 3D printing in resin? Or you just can’t figure out which one of our five resins to choose? Then this blog post is perfect for you!

(more…)

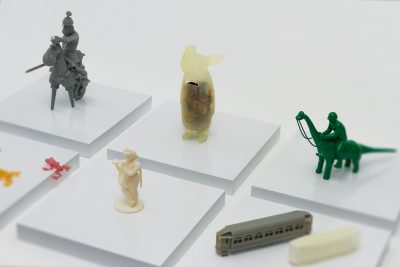

3D Printing Materials Overview: 100 Materials & Finishes Explained

With such a great variety of 3D printing materials to choose from, it can be difficult and confusing to find the right one. But don’t worry — in this post, we’ll discuss all major 3D printing materials and provide you with small previews and links to learn more about each.

(more…)

Top 5 Reasons to 3D Print through a Service Bureau

Owning and operating a 3D printer can be rewarding to go from design to final finished product all on your own. However, certain aspects like the time spent troubleshooting and optimizing settings to produce quality prints can get tedious. Or after significant investment in time and equipment you may find that you’ve just reached the limits of your 3D printers’ capability, and you would like more options.

(more…)

Top Four 3D Printing Materials For Jewelry Designers: Gold, Silver, Brass, Bronze

The most common misconception about 3D-printed jewelry is that it is printed in metallic plastic. This is not the case: it is produced as a real, solid piece of jewelry made out of the precious metal of your choice.

In this blog post, we will have a closer look at the four best and most popular materials for jewelry designers. (more…)

How Long Does It Take To Order A High-Quality 3D Print Online?

We frequently receive questions about how long 3D printing takes. That’s why we want to explain to you how fast different materials are shipped, what you can do if you need a 3D print urgently, and how our production times are calculated.

(more…)

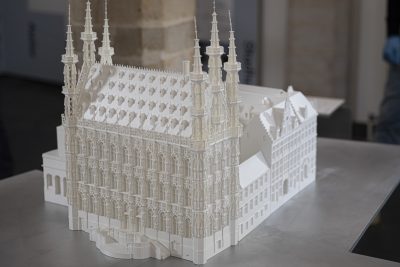

Recreating Leuven Town Hall In Intricate Detail Using 3D Printing And 100% Re-Used Powder

Leuven is a hotbed for innovation, renowned for its world-famous university and scientific and research-based institutions. The city is also prominent for its drive towards sustainability, gaining accolades such as the European Green Leaf Award (EGLA) and the title of European Capital of Innovation (iCapital) in the last few years.

Stad Leuven is constantly investigating ways to combine innovation and climate-change initiatives to improve the lives of residents, typically working with local suppliers and businesses that share their ethos. That’s why they contacted our parent company, Materialise, to help with their latest project, an intricate 3D-printed model of Leuven’s Town Hall.

Leuven Town Hall: a gothic masterpiece

Leuven Town Hall (Stadhuis in Dutch) is over 500 years old, so it’s normal that the building needs a bit of a renovation. Certain areas will have improved accessibility, while other structures will be worked on in the future. The restoration plan was the inspirat

How To Get An Instant Price For Your 3D Prints

Are you thinking about a really cool 3D design but you’re on a budget and don’t know in which material you should print it? Or maybe you want to know how much a print will cost to make sure that the sizes you would like are affordable? For example, will polyamide be more affordable than resin for your print?

To help you find the answer to all these questions, read on to discover how to get an instant price quote for your 3D print on our platform.

(more…)

A Groom-To-Be Creates His Own 3D-Printed Wedding Band For The Most Special Day Of His Life

Wedding days are special days for everyone, and Daniel Weinberger is no exception. To celebrate love and to tie the knot with his beloved wife, this creative IT professional decided to make a custom-made 3D-printed wedding band.

Based in California, Dan has been a long-term fan of 3D printing. Back when he was still in school, he was fascinated with SolidWorks, a 3D CAD software that helps designers create authentic design experiences. Even though he built his career in IT, his interest in design and 3D printing didn’t cease.

“I’ve known about 3D printers for years! Currently, I work in medical device production, and our R&D department has resin printers to quickly prototype and design products we make. It’s nice to have the possibility to see how 3D printing works!” says Dan.

Daniel Weinberger, the maker & designer of the 3D printed wedding band. Photo credit: Daniel Wenberger

Creating a personalized wedding band is a beautiful way to honor a unique bond with your partner