From Swarovski Competition To Reusable Bag: How An Innovative Designer Created A Fully 3D-Printed Purse

Since 2009, when we launched our i.materialise platform, our mission is to enable creative people worldwide to design and sell their unique 3D-printed objects. One of the makers who caught our attention is Marta Cherednik, a Singapore-based 3D printing designer who runs a design studio MALINKO.

Originally from St. Petersburg, Russia, Marta has quite a peculiar background story. First, she studied geology. After graduating, she moved to Australia, where she worked in mines for a few years as a geologist. Later on, she decided to change her career. She was interested in learning how things are made and how to find a creative outlet for her ideas, so she studied Industrial Design. For seven years, she worked for an Australian train company, where she honed her skills in designing trains and learning about highly technical aspects of industrial design.

Despite the exciting job, she wanted to express her creativity, even more, so she started designing small 3D-printed objects. Her des

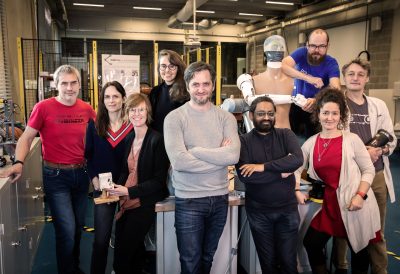

Transformative TV: 3D Printing Helps Create New Realities For People With Disabilities

Lien is a rock guitarist with a degenerative spinal condition who used to play seated on a box in a corner — now she commands the stage from her throne. Catering manager Debby was born without a left hand — today, she serves tables as efficiently as any of her waiters. Two very different dreams have become reality. And the team at Materialise Mindware used 3D printing to help make it happen.

(more…)

Castles In The Air? How 3D Printing Elevates Architecture

From aerospace to mass customized wearables, 3D printing brings the house down in so many business verticals — including architecture.

Imagine: The architect sits at their drafting table, their head filled with lofty designs. When it comes to helping their clients and partners see what’s in their mind’s eye, sketches and virtual renderings can only get them so far.

That’s where 3D printing comes in: one of the technology’s benefits is that it can expand design freedom.

Let’s look at four times architects were able to add new dimensions to their designs.

Sagrada Familia

A 3D model of a Sagrada Familia cathedral presented in the 3D printing software Magics by Materialise.

The team working on the world-famous Sagrada Familia cathedral in Barcelona has been using 3D printing since 2001. But even back in the late 19th century, the architect Antoni Gaudí understood the importance of moving from 2D to 3D and would often handcraft models of the elaborate building to get a be

A Groom-To-Be Creates His Own 3D-Printed Wedding Band For The Most Special Day Of His Life

Wedding days are special days for everyone, and Daniel Weinberger is no exception. To celebrate love and to tie the knot with his beloved wife, this creative IT professional decided to make a custom-made 3D-printed wedding band.

Based in California, Dan has been a long-term fan of 3D printing. Back when he was still in school, he was fascinated with SolidWorks, a 3D CAD software that helps designers create authentic design experiences. Even though he built his career in IT, his interest in design and 3D printing didn’t cease.

“I’ve known about 3D printers for years! Currently, I work in medical device production, and our R&D department has resin printers to quickly prototype and design products we make. It’s nice to have the possibility to see how 3D printing works!” says Dan.

Daniel Weinberger, the maker & designer of the 3D printed wedding band. Photo credit: Daniel Wenberger

Creating a personalized wedding band is a beautiful way to honor a unique bond with your partner

How To Get Your Perfect Brass 3D Print

Are you thinking about 3D printing in brass? Would you like to know more about the material and all the available finishes? Are you interested in finding out how your 3D design is turned into a perfect brass 3D print? Would you like to discover some design tips and tricks for your next brass 3D print? Then read on, because you will find the answers to all your questions in this blog post!

(more…)

Get To Know Our Rubber-Like Material And Its New Extra Smooth Finish

In autumn 2019, we announced our new and improved TPU offering! At i.materialise, we’re always working hard to expand our range of materials and finishes. And now, we’re introducing a new finish to give Rubber-like parts an ultra-sleek look: extra smooth.

(more…)

Surprise Your Loved One For Valentine’s Day: 10% Off On Custom 3D-Printed Jewelry

As we are approaching February, many of us start to think about celebrating love and surprising our better halves with a special gift. While a box of chocolate and flowers never go out of fashion, maybe this year you would like to express your feelings in a unique way that will charm your loved one. (more…)

3D Printing Trends for 2021: A Year of Radical Renewal

As our parent company, Materialise, marks its entry into the 4th decade of 3D printing in 2021, we’re entering a decade with the potential for radical renewal. The COVID-19 crisis has had an enormous effect on every industry and continues to propel us into a space where we need to think differently. To think about where we need to push the boundaries of innovation and creativity.

With this being said, the legacy of 3D printing starts in 2021 with three key trends: going back to the drawing board to rethink manufacturing; enabling the personalization of not only products, but also 3D printers themselves; and creating new solutions, fast.

(more…)

Best Wishes For 2021!

From the whole team here at i.materialise, we’re wishing you a safe and happy holiday season!

(more…)

30 Years Of Innovation: Dependable SLS Enables Sustainability In AM

We’re wrapping up our 30th-anniversary blog series for our parent company, Materialise, with a look at the final 3D printing technology in our portfolio: selective laser sintering (SLS). SLS, with i.mat offerings in Polyamide (SLS), Alumide, and Polypropylene, has been offered at Materialise since 1998. Over the past 22 years, our team has worked with this technology to reliably print application after application. This next decade, we’re turning our sights on sustainability, and SLS has a major role in enabling our customers to order prints that are manufactured in a more sustainable way with our new Bluesint PA12 material.

(more…)