Untreated

Natural PU Coating

Yellow Gold-Plated Polish

Yellow gold plating is applied by using an electroplating process that covers your model with a thin layer of 18K yellow gold. An additional PU coating provides extra protection, giving you a 6-month guarantee on the plating.

This finish adds 3 days to the standard lead time.

Rhodium-Plated Polish

Rhodium plating is applied by using an electroplating process that covers your model with a thin layer of rhodium. It prevents your model from getting scratched or tarnished and has a cold white color tone.

Typically, rhodium is used for jewelry. It eventually wears off due to skin contact and interaction with natural elements. As a result, rhodium plating must be reapplied, depending on how often a piece of jewelry is worn. Our rhodium plating finish comes with a 6-month guarantee.

This finish adds 3 days to the standard lead time.

Chrome-Plated Polish

Chrome plating is applied by using an electroplating process that covers your model with a thin layer of chromium. First, we apply a very thin layer of copper to your model followed by a layer of nickel, which acts as a base to attach the chromium to. Finally, the chromium layer is added.

The chrome-plated layer has a polished, elegant aesthetic, provides some corrosion resistance and increases the surface hardness of your model. It is a more affordable imitator of chrome. This decorative chrome plating is traditionally used on car parts and tools. Because the base layer of chrome-plated parts contains nickel, we don’t recommend using this finish for jewelry. Some release of nickel might be possible during skin contact.

This finish adds 6 days to the standard lead time.

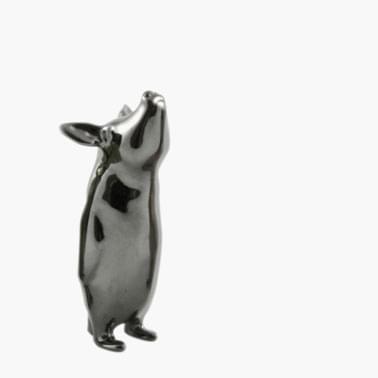

Black Color-Plated Polish

We offer a black-color plated finish, which is applied by using an electroplating process in combination with a colored PU coating. Your model will first be finished with a very thin layer of palladium and silver. We then add the color by applying a liquid, colored PU coating, which is cured in the oven in the final step. We offer a 6-month guarantee on this colored PU coating.

This finish adds 6 days to the standard production time.

-for-Luftwaffe-aircraft-by-Christoph-Vernaleken.jpg)