Design Specifications

Pricing Info

The pricing for Gold is based on model volume, which is the volume of your model used to calculate the material cost (mm³).

Additionally, a startup cost is applied to the price of your model. This is a fixed cost independent of the parameters of your model. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Hallmarking

The hallmarking of gold is a way of guaranteeing that you’re getting the correct level of purity in your precious metals. We don’t use an assay office; instead, we have permission from the Royal Mint of Belgium to mark cast models with a master (also called a maker) and purity stamp. The purity mark will indicate the purity of the precious metal. For 14k gold, the mark is a diamond (or rhombus) with the text “au 585”. For 18k gold, the text “au 750” is featured in the same diamond shape.

The master or maker stamp has been registered and approved by the Royal Mint of Belgium. It displays the symbol of a lightbulb with the letters “i.m” inside the outline of a barrel.

Hallmarking is performed to the highest extent possible, either with a laser or by stamping the metal. However, if there is a risk of damaging the final product, the marks may be missing. In every case, you will always receive an invoice as proof of authenticity. Pursuant to the Belgian Law of 11 August 1987 on the warranty of works on precious metals and the Belgian Royal Decree of 18 January 1990 on the warranty of works on precious metals, i.materialise guarantees that the object of the Invoice fulfills the standards of purity for 14K gold at 58.5% purity or 18K gold at 75% purity, whichever is applicable.

For customers outside the EU, excluded for Switzerland, hallmarking is not provided.

i.materialise complies with Belgian legislation and the free movement of goods in Europe.

Typical Use

Gold is mostly used for jewelry.

Technology

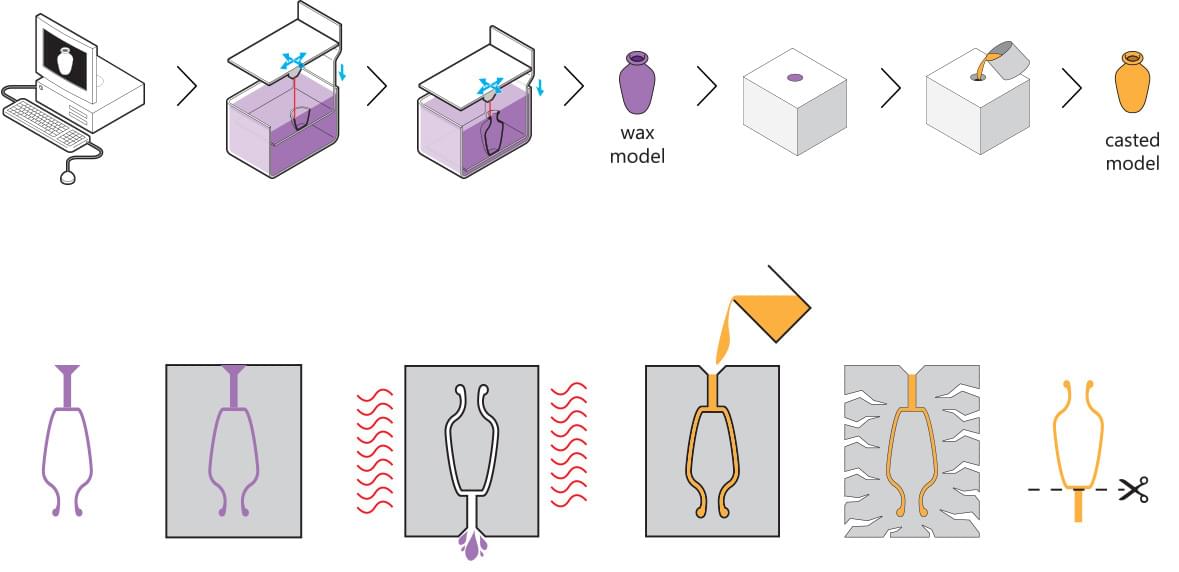

Wax 3D printing and lost wax casting are used to build your design when using this material. The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure your model doesn’t fall apart. These support structures are automatically generated and manually removed after the printing process. After support structures are removed and your model is cleaned, the model can be prepared for casting.

First, one or more wax sprues will be attached to your model. Next, the sprue and model will be attached to a wax ‘tree’, together with a bunch of other models. The tree is then placed in a flask and covered in fine plaster. When the plaster solidifies, it forms a mold for gold casting. The plaster mold is then put in an oven and heated for several hours to a point where the wax is completely burned out.

Then, molten gold is poured in to fill the cavities left by the wax. Once the gold has cooled and solidified, the plaster mold is broken and the gold models are removed by hand and polished.

Additional Information

- Because pure gold would be too soft for durable jewelry, solid gold is mixed with an alloy (usually with metals like silver, copper or zinc) to harden the material for longer wear

- Due to the nature of the process (lost-wax casting and printing) used in the production of gold, interlocking or enclosed parts are not possible

- In order to comply with European regulations (REACH), we use nickel-free white gold. Consequently, the color of white gold models may appear slightly yellow

- Please also be aware that we do not use rhodium plating to whiten our white gold because plating eventually wears off. If you really want to whiten your model, you can always turn to your local jeweler to apply rhodium plating. Keep in mind that this plating will need to be reapplied each time it wears off and that the natural, slightly yellow color of white gold will reappear

- 14k yellow gold consists of 58.5% gold, 12.6% silver, 25.4% copper, and 3.5% zinc

- 14k white gold consists of 58.5% gold, 17.43% silver, 9.13% copper, 4.15% zinc, and 10.79% palladium

- 14k red gold consists of 58.5% gold, 39.5% copper, and 2% zinc

- 18k yellow gold consists of 75.2% gold, 12.1% silver, 10.8% copper, and 2.1% zinc

- 18k white gold consists of 75.2% gold, 10.42% silver, 5.45% copper, 2.48% zinc, and 6.45% palladium

- 18k red gold consists of 75.3% gold and 24.7% copper