Design Specifications

Pricing Info

The pricing for ABS is based on:

- Model volume: The volume of your model is used to calculate the material cost (mm³)

- Model surface

- Orientation: The way your model is positioned on the print platform will impact support generation and therefore the price

Additionally, a startup cost is applied to the price of your model. This is a fixed cost independent of the parameters of your model. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Typical Use

Technology

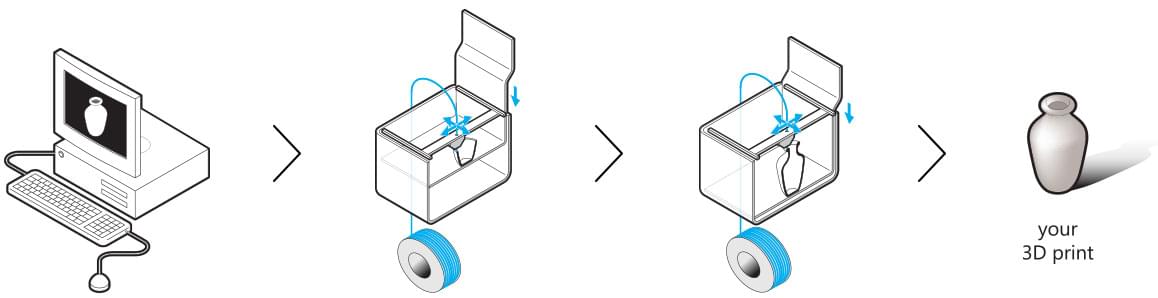

Fused Deposition Modeling (FDM) is a filament-based 3D printing technology where a temperature-controlled head extrudes a thermoplastic material layer by layer onto a build platform. The principle is simple and can be compared to that of a glue gun, where the stick of glue is heated up until it melts and is then pushed through a fine nozzle at the front of the glue gun.

In an FDM printer, a long plastic wire (filament) is used instead of glue. The wire is fed from a spool to the nozzle where it’s liquefied and ‘drawn’ on the platform to immediately harden again. The nozzle moves to drop the material at the correct location, drawing your model line by line. When a layer is drawn, the platform lowers by one layer thickness (0.18 - 0.25 mm) so the printer can continue with the next layer.

When your model contains overhanging sections, a support structure is created where needed and printed in a water-soluble material. Because the material of the model cannot be deposited in the air, the support structure prevents it from falling down. This support material is fed through another nozzle. Afterwards, the support structure is manually removed as much as possible and then put into a bath with special soap, so every remaining bit of the support material dissolves.

Additional Information

- Because the support material used for ABS is water-soluble, it’s possible to print complex geometries like interlocking and moving parts

- ABS is difficult to post-process because of the layering and the hardness of the plastic

- Extra finishing steps such as sealing, primer or paint are available on Materialise OnSite, our other online 3D printing platform

- ABS is water permeable

- ABS is UV-resistant

Additional Materials

We want you to have access to as many 3D printing materials as possible, so you can make the best choice for your project. If you didn’t really find what you were looking for on i.materialise, you might want to take a look at Materialise OnSite. OnSite is our other online platform, mainly used by professionals who need rapid prototyping and manufacturing in an industrial environment.

This means you can additionally find these materials on OnSite:

- ABS-ESD7 : A durable and electrostatic-dissipative material. Suitable for applications where static charge could impair performance.

- PC : Due to its excellent impact strength and temperature resistance, polycarbonate is among the most widely used industrial thermoplastics.

- PC-ABS : A blend of polycarbonate (PC) and ABS, which combines the strength and heat resistance of PC with the flexibility of ABS.

- Ultem 9085 : Strong, lightweight and flame-retardant (UL94-V0 rated) material with superior mechanical performance and strength-to-weight ratio.