3D Printing Business Ideas: 3 Essential Tips

Learn how to turn a 3D printing business idea into reality: start with an idea that adds value, keep your costs low, and learn from successful 3D printing start-ups. Read on to see which 3D printing business models generate profit.

1. Come up with a 3D printing business idea that adds value

Are you searching for a business idea that involves 3D printing? Make sure that you come up with a product that sells because it is innovative. It might not be enough to sell an object ‘only’ because it is 3D printed − it also needs to give customers added value that traditional manufacturing cannot provide.

3D printing can create things that are impossible to create with traditional manufacturing. A striking example is the One_Shot.MGX stool by Patrick Jouin. This is a stool that has been printed in one piece – no screws needed, no pieces to attach. These features can bring a big advantage to all kinds of objects that would require a lot of manual labor with traditional techniques.

3D printed in one piece: One_Shot.MGX by Patrick Jouin. © Victoria and Albert Museum, London.

3D printing also enables you to produce mass customization products. One of the great things about 3D printing is that you don’t have to order 10,000 units of an item to make it affordable for customers and put it on the market. You can start producing and selling as of a single print. So, turn this to your advantage and offer a product that matches your customer’s needs. Come up with an idea that is unique, customizable, and fits demand perfectly!

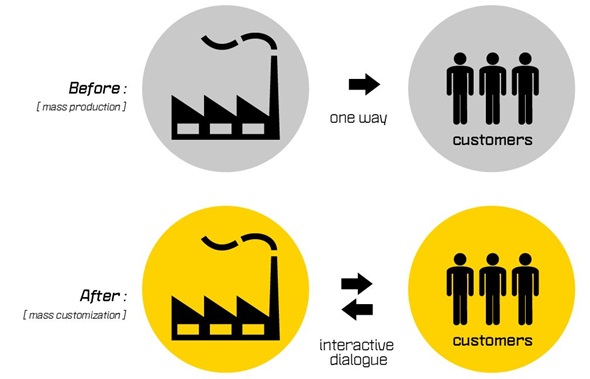

Mass customization: the production workflow of the future. Make sure to adapt to the 3D printing business model. © Musen Lin.

Maybe you want to create a browser-based 3D design tool that allows other users to create 3D printable items? Or maybe you want to create an app that lets your users tweak and customize their products? Personalizable jewelry, perfectly fitting glasses frames, 3D selfies – this great technology offers unlimited possibilities and lets you start an interactive dialogue between customers and production.

Still, it might be difficult getting started. That’s why we want to present ways of finding funding and keeping your starting costs as low as possible.

2. Keeping costs low

To start your 3D printing business, there are two important things to keep in mind: find funding and keep your costs low. Luckily, everybody is talking about 3D printing today − and so there are lots of funding programs out there for your 3D printing start-up.

Here’s an example: projects like FABulous create and support a service ecosystem for 3D printing start-ups. They bring together investors and entrepreneurs. Make sure to search for similar projects in your region.

Another way to fund your business is to use the power of the crowd: we’ve already worked with start-ups that used crowdfunding platforms like Kickstarter and IndieGoGo to turn their dream of a 3D printing business into reality.

In addition to securing funding, one of your most important financial challenges is to keep costs as low as possible. However, running and maintaining a printing facility requires a lot of seed capital, which might be a risky investment when you don’t yet know how your product will sell. And that’s where it makes sense to think about outsourcing production to minimize costs and risks.

i.materialise has developed several interfaces (APIs) that allow your business to connect with our systems. You simply feed the data from your apps or websites to us − and our 100+ 3D printers do the rest! It’s the best risk-free starting point for any 3D printing business idea.

We have over 10 APIs in place − from referral models to white label partnerships − and our aim is to offer as much of our website’s functionality through the APIs as we can. However, some APIs might be more useful for your business than others − the optimum way to connect to i.materialise depends on your business model.

See more examples, and learn how to connect your business to our printing facility, here.

3. Learn from successful 3D printing start-ups

So, how do other companies do it? It’s always a good idea to check what’s out there before jumping in. Be sure to visit this page to see some examples.

One of the best examples is Trinckle − an online platform that offers added customization to 3D prints. For example, you can use Trickle to personalize hooked badge holders that make using office equipment safer during the COVID-19 pandemic.

A huge advantage of 3D printing is its ability to customize, and Trinckle steps in to give customers added personalization for a variety of innovative 3D-printed designs.

When users visit the Trinckle website, they place their orders there. Meanwhile, Trinckle connects to a printing company’s API, i.materialise in the case of the hooked badge holders and hands-free door openers, to send the ordered models to the 3D printing infrastructure. This way, Trinckle avoids the huge expense of building their own printing facility, and we get to do what we do best: 3D printing on our cutting-edge industrial printers.

Visit our dedicated API page to learn more about connecting your business to our 3D printing factory. Want to see what your product looks like as a 3D print? Upload it to our website – our online 3D printing service will take care of the rest. Also, make sure to browse our overview of available 3D printing materials here. You’ll be surprised to see what is already possible today.

Recommended Articles

No related posts.