Top Four 3D Printing Materials For Jewelry Designers: Gold, Silver, Brass, Bronze

The most common misconception about 3D-printed jewelry is that it is printed in metallic plastic. This is not the case: it is produced as a real, solid piece of jewelry made out of the precious metal of your choice.

In this blog post, we will have a closer look at the four best and most popular materials for jewelry designers. (more…)

How to Improve Your Creative Business with 3D Printing

If you are a designer, jeweler, or creative mind starting your own company, you’ll probably have heard about 3D printing. You might even have thought about introducing it to your company or creative project. However, you may not know where to start or how it can improve your business.

If that is the case, we have some good news for you: it’s easier than you think and well worth your while! (more…)

5 Super Useful 3D-Printed Bicycle Accessories

Whether you’re a total gearhead or not, cycling is fun, environmentally friendly, and all-around awesome. And with 3D printing, these designers are making their rides even cooler! Pimp your own bicycle with their creative designs or get inspired to make your own custom bicycle gadgets.

(more…)

How Long Does It Take To Order A High-Quality 3D Print Online?

We frequently receive questions about how long 3D printing takes. That’s why we want to explain to you how fast different materials are shipped, what you can do if you need a 3D print urgently, and how our production times are calculated.

(more…)

The International Space Station Welcomes The Moon Gallery Art Collection Onboard, Including A Miniature 3D-Printed Cube

Although the Moon is around 238,855 miles (or 384,400 km away), humanity has always been fascinated by it. From ancient lunar calendars to the Moon landing in 1969 to low and high tides affecting shorelines at this very moment, Earth’s natural satellite is entwined in our past and present. But how will it shape our future? Discover how the Moon Gallery — including a 3D-printed cube — aims to teach us about the unique conditions in space for future generations and extend humankind’s cultural reach into this final frontier.

(more…)

To See A Song: Materialise Designers Turn Abstract Idea Into Personalized Car Speaker Grill Design

This project began with an idea that was quite basic: giving automotive brands a way to offer personalization in luxury cars. From there, the Design and Engineering team of our parent company, Materialise, tapped deep into the design portion of their role, creating a concept that would enable consumers to make a car truly their own. A design that would allow drivers to not only listen to their favorite song while driving down the highway but to see it as well.

(more…)

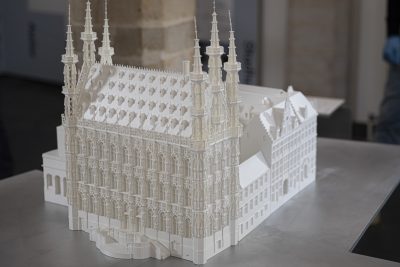

Recreating Leuven Town Hall In Intricate Detail Using 3D Printing And 100% Re-Used Powder

Leuven is a hotbed for innovation, renowned for its world-famous university and scientific and research-based institutions. The city is also prominent for its drive towards sustainability, gaining accolades such as the European Green Leaf Award (EGLA) and the title of European Capital of Innovation (iCapital) in the last few years.

Stad Leuven is constantly investigating ways to combine innovation and climate-change initiatives to improve the lives of residents, typically working with local suppliers and businesses that share their ethos. That’s why they contacted our parent company, Materialise, to help with their latest project, an intricate 3D-printed model of Leuven’s Town Hall.

Leuven Town Hall: a gothic masterpiece

Leuven Town Hall (Stadhuis in Dutch) is over 500 years old, so it’s normal that the building needs a bit of a renovation. Certain areas will have improved accessibility, while other structures will be worked on in the future. The restoration plan was the inspirat

3D Printing Technologies: Laser Sintering

Contrary to popular belief, there’s not a one-size-fits-all approach to 3D printing. Although we offer 17 different materials and over 90 possible color and finish combinations, it takes us several different technologies to get the job done. In general, 3D printing technologies can be split up into two groups: direct and indirect 3D printing. The main difference lies in the fact that the design is made from 3D printing (direct) or 3D printing was used in the process of creating your model (indirect). In this article, we’ll dive into laser sintering, by far one of the most popular 3D printing technologies, and an example of a direct 3D printing technique. (more…)

How 3D Printing In Polyamide (MJF) Really Works

In this blog, we take a look at how 3D printing in Polyamide (MJF) works and dig into the differences between our 3D printing polyamides. (more…)

“3D Printing Is A Revolution”: A Talk With Artist Koen Van Daele

Long-time i.materialise user Koenraad Van Daele combines a classical background with modern techniques, creating some truly inspiring designs. In this user spotlight, we talk to him about the inspiration and techniques behind his work and why 3D printing is so important to him.

When Koen began his first project with i.materialise in 2008, it marked a significant shift in his journey through the art world. Classically trained as a marble sculptor from the age of 18, including two years spent in Carrara, Italy — the center of the stone sculpture industry — Koen now mainly focuses his attention on vector art and 3D modeling. But what inspired the shift?

“I bought my first computer in the 90s and started using graphic programs,” he tells us. “I realized that I had a talent for drawing with software. When you work as a web designer or system engineer like I did, it’s very easy to go from one platform to another, and in between, start designing for 3D.”

The perks of 3D printing

H