3D Printing Materials Overview: 100 Materials & Finishes Explained

With such a great variety of 3D printing materials to choose from, it can be difficult and confusing to find the right one. But don’t worry — in this post, we’ll discuss all major 3D printing materials and provide you with small previews and links to learn more about each.

We’ll talk about all 21 materials and more than 100 finishes that we offer here on i.materialise now! To make things easier, we’ll split this article into the following three sections:

- Plastic 3D printing materials

- Metal 3D printing materials

- 3D printing in other materials

Plastic 3D printing materials

For plastic 3D printing, the most popular choice is Polyamide — a strong and flexible nylon plastic. Its natural color is white, but it can be dyed in several colors. Its surface is somewhat rough, but it can be smoothed out. The printing option — laser sintering and Multi Jet Fusion — use powdered polyamide, enabling designers to use it for interlocking and moving parts (i.e., creating a chain).

Polyamide (SLS)

Natural finish

Dyed finishes

Satin

Polished

Spray paint

Polyamide (MJF)

Natural

Dyed

Polished

Dyed and polished

Alumide

Polyamide powder can also be mixed with Aluminum particles.

Natural

Dyed

Polypropylene

3D-printed Polypropylene has properties similar to the injection-molded kind, and the natural finish has a sandy, granular look in a translucent off-white color.

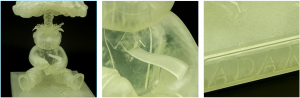

Another popular plastic choice is based on resin. Resin 3D prints are made from a liquid photopolymer cured with UV light during the stereolithography 3D printing process and feature a smooth surface. Resin printers can be huge — our biggest printers can print up to 2,100 millimeters! With five different resin options, you’ll find what you’re looking for, whether that’s prints with an extremely high level of detail or our more affordable option: Gray Resin.

Gray Resin

Natural, basic

Natural, support marks removed

Spray paint (A-side)

High-Detail Resin

Natural

Mammoth Resin

Our Mammoth Resin prints are available with a natural finish or spray painted in the following colors:

Standard Resin

Natural, basic

Natural with support

By opting for this finish, you’ll receive your part with the support structures still attached. You can remove them yourself with tools and sanding paper.

Transparent Resin

Natural

Color

By adding a small amount of paint to the varnish, we can create a colorful look in white, yellow, red, green, blue, gray, and black.

ABS

Our final plastic material is ABS. This material will give you a print that is strong and accurate. ABS is very useful for functional applications because it matches 80% of the properties of real injected production material. However, the surface quality of the models produced with this material is rough in comparison with other materials.

Metal 3D printing

All of our metal materials are printed from their powdered forms. While Titanium is laser-sintered directly, Steel prints are created with the use of a binding agent and curing oven.

Aluminum

Aluminum is a great option for strong, lightweight parts. You’ll notice a subtle sparkle caused by the presence of silicon in the alloy.

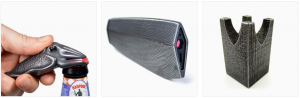

High-Detail Stainless Steel

If you’re looking for an extreme level of detail, High-Detail Stainless Steel is probably what you’re looking for.

Matte

Satin

Gloss

Steel

Natural, polished

Natural, unpolished

Gold-plated, polished

Gold-plated, unpolished

Black, polished

Black, unpolished

Brown, polished

Titanium

Titanium is the strongest 3D printing material out there. It has a matte look and comes with an upscale price.

Matte

Satin

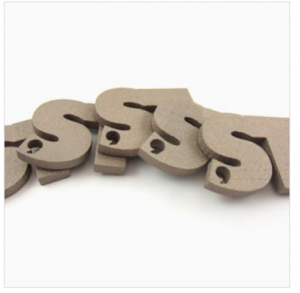

Our precious metal models come in silver, gold, brass, bronze, and copper. Most of these metals have several finishing options.

Brass

Untreated

Natural PU coating

Yellow gold-plated polish

Red gold-plated polish

Rhodium-plated polish

Chrome-plated polish

Black color-plated polish

Bronze

Polished PU coating

Natural PU coating

Natural, uncoated

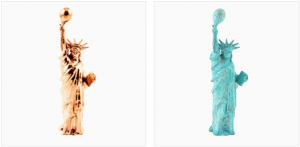

Copper

Although we polish copper models magnetically and by hand, the material is very sensitive to oxidation. By nature, copper has a reddish color but it will tarnish and turn green (verdigris) when it starts to corrode.

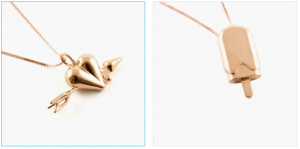

Gold

Gold objects can be created in 14k and 18k and in yellow, red, or white gold.

14K

18K

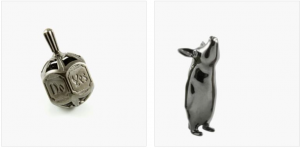

Silver

Silver comes in five different finishes, including our ‘antique finish’.

Gloss

High gloss

Antique

Sandblasted

Satin

3D printing in other materials

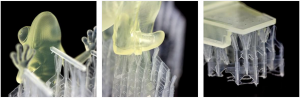

Multicolor

Multicolor is the only material that enables you to print models in more than one color. Models made of multicolor are constructed from a fine, white, granular sandstone powder. The interior of the model stays white while coloring print heads ‘paint’ the exterior of your model.

Rubber-like

3D prints in Rubber-like are highly flexible and printed in Multi Jet Fusion machines. The surface of this material is fine and granular. Technically, Rubber-like is a plastic material; however, we put it in the ‘other’ category to highlight its extraordinary material characteristics.

Natural

Dyed

Extra smooth

Learn more about each specific 3D printing material in our overview table here. You can discover more information about all of our 100 different materials and finishes there. Once you’ve found the material of your choice, upload your 3D file here, select your material, and receive a high-quality 3D print right at your doorstep.