Which 3D-Printed Resin Is Right For You?

Are you thinking about 3D printing in resin? Would you like to know more about the technology behind 3D printing in resin? Or you just can’t figure out which one of our five resins to choose? Then this blog post is perfect for you!

The technology: Stereolithography

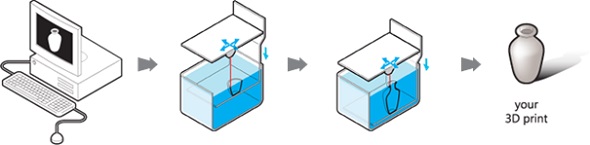

Stereolithography, the mother of all 3D printing technologies, has been around at Materialise since 1990. It is one of the most widely used 3D printing technologies for plastic 3D models. Instead of using powder or filament, Stereolithography technology uses a liquid resin to produce 3D prints. Since we are dealing with a liquid material, additional support structure is necessary for overhanging parts and cavities.

The 3D printing process takes place in a large tank filled with liquid resin. To start the process, a layer of UV-sensitive liquid polymer is spread over a platform. Then, by applying a UV laser, selective parts of the liquid are hardened, depending on where the laser beam strikes. The remaining material in the tank stays liquid. In the next step, the platform, together with the model, is lowered, making room for the next layer of polymer to be drawn on top of the previous one. Again, the laser beam is applied to harden selective parts of the liquid material.

This process is repeated until the model is finished. The required supports (for overhanging parts and cavities) are automatically generated, and once the entire process is done, the model can be raised out of the tank and the supports are manually removed.

5 Different 3D-Printed Resins

The main advantages of our 3D-printed resins are smooth surfaces, high-quality, detailed prints, and a huge variety of finishing and post-processing possibilities. But let’s take a look at each of the five 3D-printed resins in depth.

Standard Resin

Our most recently added resin is Standard Resin. It offers great quality at a low price, making it the ideal low-budget material. It is available with or without support, which you can manually remove with tools and sanding paper. Standard Resin has a high level of detail, is translucent, feels smooth to the touch, and is easy to paint and post-process.

Dino Rider in Standard Resin by Bert De Niel

Gray Resin

Gray Resin, is a very smooth resin — much smoother than almost all other 3D printing materials — and easy to paint. The standard finish comes in Natural Gray (Air Force Gray), but in total, there are nine finishing colors to choose from: white, black, blue, green, yellow, gray, red, orange, and brown. However, you can also paint it yourself.

As you can read in this article, Gray Resin is the perfect material to 3D print figurines.

“Strong Bot” 3D Printed in Gray Resin and hand-painted by Onorio

Mammoth Resin

The main advantage of our Mammoth Resin material is that you can print in huge sizes: 2,100 x 700 x 800 mm. And it comes with the same high quality and smoothness as the other resins. So, if you want to print a large piece, hesitate no longer, and choose our Mammoth Resin. Discover our favorite Mammoth Resin designs in this article.

Bike frame in Mammoth Resin by James Novak

Transparent Resin

As the name already reveals, Transparent Resin is the material of your choice if you want to print in a transparent material. The material is water-resistant by nature and ideal for smaller models that need a smooth, high-quality, transparent surface.

Learn how to get the perfect Transparent 3D print and get inspired by this amazing cathedral printed in transparent resin.

3D-Printed Transparent Resin

High-Detail Resin

Finally, our last resin, High-Detail Resin, doesn’t use Stereolithography but instead a 3D printing technology called PolyJet. So how does this work? It jets ultra-thin layers of resin onto a building platform. Each layer is immediately hardened by UV light. This process is continued layer by layer until the model is completed.

Again, supports are necessary for complicated geometries, which can be removed by hand or water jetting once the printing process is finished. If you need a small model with an enormous level of detail and a smooth surface, choose our High-Detail Resin.

Animation figure in 3D-printed High Detail Resin by Hanne Maes

Now, you’re ready to upload your 3D model, pick the material, and turn your idea into reality.

Don’t forget to read the design guidelines for each 3D-printed resin to make the most of your 3D prints!

Recommended Articles

No related posts.