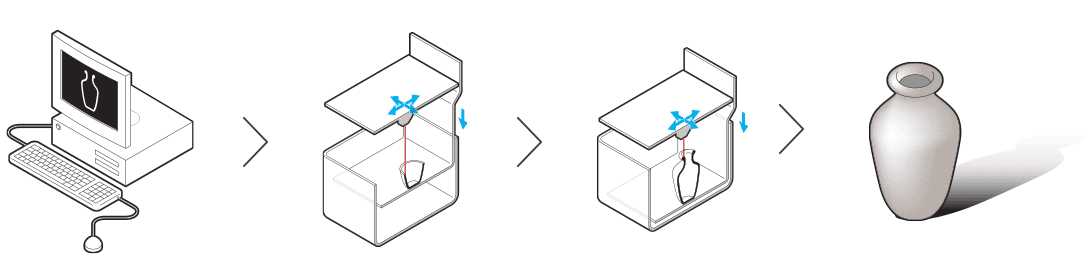

How It Works

PolyJet prototyping technology is used to build your design with this material. Objet’s patented PolyJet inkjet technology works by jetting photopolymer materials in ultra-thin layers onto a build tray, layer by layer until the model is completed. Each photopolymer layer is cured by UV light immediately after being jetted, producing fully cured models that can be handled and used immediately. The gel-like support material, which is specially designed to support complicated geometries, can easily be removed by hand and water jetting.

Materials

Multicolor+

- The only material that offers full color models

- Surface has a layered plastic look

- Allows a lot of freedom in design

- Mostly used for items with limited functionality

High-Detail Resin

- Ideal for small and/or very finely-detailed visual models

- Allows a lot of freedom in design

- Mostly used for non-functional items

Trivia

Did you know that?

- In 2012, Objet announced that it agreed to merge with Stratasys in an all-stock transaction.

- Hollywood seems to love PolyJet Technology. Movies like Iron Man, Real Steel, Pacific Rim, Coraline and Avatar have all used it in some kind of way.

- Materialise has been using this technology since 2006.