How To Get Your Perfect Brass 3D Print

Are you thinking about 3D printing in brass? Would you like to know more about the material and all the available finishes? Are you interested in finding out how your 3D design is turned into a perfect brass 3D print? Would you like to discover some design tips and tricks for your next brass 3D print? Then read on, because you will find the answers to all your questions in this blog post!

(more…)

Get To Know Our Rubber-Like Material And Its New Extra Smooth Finish

In autumn 2019, we announced our new and improved TPU offering! At i.materialise, we’re always working hard to expand our range of materials and finishes. And now, we’re introducing a new finish to give Rubber-like parts an ultra-sleek look: extra smooth.

(more…)

How to Get Your Perfect Sterling Silver 3D Print

Are you thinking about 3D printing in Sterling Silver? Do you wonder how we create a real physical Sterling Silver object from your 3D design? Would you like some tips and tricks for your next Silver 3D print? In this case, this blog post is for you.

(more…)

30 Years of Innovation: Bringing 3D Printing’s Benefits to Metal

We’ve passed the halfway point of our 30th-anniversary blog series, and for October, we’re looking into Metal 3D Printing. Read on to discover how our parent company Materialise utilizes Metal 3D Printing to combine AM’s advantages with tried-and-tested materials and how our team in Bremen, Germany is working to further develop the technology.

(more…)

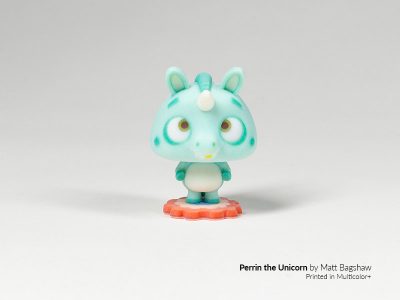

How to Get the Perfect Multicolor+ 3D Print

Have you already discovered Multicolor+, our new 3D printing material in full color?

Maybe you are thinking about 3D printing your next design with Multicolor+ but you don’t know what to expect. In this article we will explain how the technology behind Multicolor+ actually works, what colors can you expect, and how to model your 3D design to get the perfect full-color 3D print.

Here’s all you need to know about 3D printing in Multicolor+!

(more…)

Top Reasons to 3D Print with Polypropylene: Versatility, Accuracy, and 500% Elongation at Break

Polypropylene (PP) is a highly functional plastic commonly used in a wide variety of ways, such as consumer goods, packaging, and automotive applications. So, it was a perfect fit when we added PP to our portfolio of 3D printing materials in 2018. PP, a material option for the selective laser sintering (SLS) technology, offers technical capabilities that provide solutions fit for a variety of applications.

(more…)

30 Years of Innovation: Multiple Colors in One Print with PolyJet

On June 28th, we celebrated our 30th anniversary, and we’ve been celebrating every month since by highlighting a different technology on our blog. The focus for September? PolyJet. And you can save 10% on Multicolor+ and High-Detail Resin prints, the materials that use this technology, during September by using the code 30Y_PolyJet at checkout.

(more…)

30 Years of Innovation: How Stereolithography Sparked Materialise’s Inventive Ethos

On June 28th of this year, i.materialise’s parent company Materialise reached its 30th anniversary, and to celebrate, we’re looking back at a different technology on our blog each month that has made the company what it is today. During August, we’re putting the focus on Stereolithography (SLA): the technology behind our Gray, Mammoth, Standard, and Transparent Resin materials.

(more…)

30 Years of Innovation: Industry Collaboration Made Multi Jet Fusion a Reality

When Multi Jet Fusion first came on the scene a few years ago in 2016, it made a big splash. The 3D printing world was excited to become acquainted with the much-anticipated technology, also called MJF for short. Soon, many realized the potential for their prototypes and end-use parts thanks to its higher surface quality, consistent build time regardless of the number of parts, and the ability to print exceptionally thin walls.

(more…)

How 3D Printing in Aluminum Really Works

We’d like to give you an insight into how 3D printing in Aluminum really works. In this blog, we’ll take a look at the technology and inform you about all the details you’ve always wanted to know.

(more…)