Black Friday Savings: Get 15% All Weekend Long!

Give unique 3D-printed pieces this holiday season. And get them at a great price when you order between Black Friday and Cyber Monday. (more…)

How to Get Your Perfect Sterling Silver 3D Print

Are you thinking about 3D printing in Sterling Silver? Do you wonder how we create a real physical Sterling Silver object from your 3D design? Would you like some tips and tricks for your next Silver 3D print? In this case, this blog post is for you.

(more…)

30 Years Of Innovation: Stable And Durable FDM Is Ideal For Aerospace

To keep our 30th anniversary celebration going, this month we are putting the spotlight on one of the most popular 3D printing technologies: Fused Deposition Modeling (FDM). Every month since our anniversary in June of this year, we’ve been doing a deep dive on a different technology to show that there is not a one-size-fits-all approach to 3D printing. Read on to discover why FDM’s strengths lead to durable prints, and why it is the trusted go-to for aerospace and other industries that rely on certified manufacturing.

(more…)

Creating Opportunities for Creative Expression Through Custom Writing Aids

The slightest sketch of a pencil may just mean the world. Those scribbles, even when unrecognizable, are full of joy and enthusiasm. And they can change a child’s life.

(more…)

Car Enthusiast Makes First 3D Print to Bring Customization to Life

If you’re a car enthusiast like Miguel Vargas, there is no detail that is too small. Case and point: the paddle shifters on the steering wheel of his Ford Mustang.

(more…)

30 Years of Innovation: Bringing 3D Printing’s Benefits to Metal

We’ve passed the halfway point of our 30th-anniversary blog series, and for October, we’re looking into Metal 3D Printing. Read on to discover how our parent company Materialise utilizes Metal 3D Printing to combine AM’s advantages with tried-and-tested materials and how our team in Bremen, Germany is working to further develop the technology.

(more…)

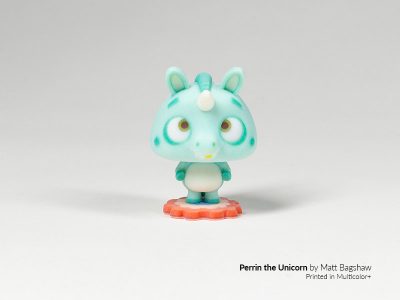

How to Get the Perfect Multicolor+ 3D Print

Have you already discovered Multicolor+, our new 3D printing material in full color?

Maybe you are thinking about 3D printing your next design with Multicolor+ but you don’t know what to expect. In this article we will explain how the technology behind Multicolor+ actually works, what colors can you expect, and how to model your 3D design to get the perfect full-color 3D print.

Here’s all you need to know about 3D printing in Multicolor+!

(more…)

Top Reasons to 3D Print with Polypropylene: Versatility, Accuracy, and 500% Elongation at Break

Polypropylene (PP) is a highly functional plastic commonly used in a wide variety of ways, such as consumer goods, packaging, and automotive applications. So, it was a perfect fit when we added PP to our portfolio of 3D printing materials in 2018. PP, a material option for the selective laser sintering (SLS) technology, offers technical capabilities that provide solutions fit for a variety of applications.

(more…)

30 Years of Innovation: Multiple Colors in One Print with PolyJet

On June 28th, we celebrated our 30th anniversary, and we’ve been celebrating every month since by highlighting a different technology on our blog. The focus for September? PolyJet. And you can save 10% on Multicolor+ and High-Detail Resin prints, the materials that use this technology, during September by using the code 30Y_PolyJet at checkout.

(more…)

5 3D Prints That Will Strike A Chord With You

We’re nearing the height of festival season, and music lovers all around the world are beginning to get together to hear their favorite artists. But you don’t need to travel to get inspired by music! In this article, we’re celebrating that audible artistry by sharing various musical innovations made possible by 3D printing.

(more…)