Design Specifications

Pricing Info

The pricing for Standard Resin is based on model volume, which is the volume of your model used to calculate the material cost (mm³)

In addition, a startup cost is applied to the price of your model. This is a fixed cost independent from the parameters of your model.

Typical Use

Technology

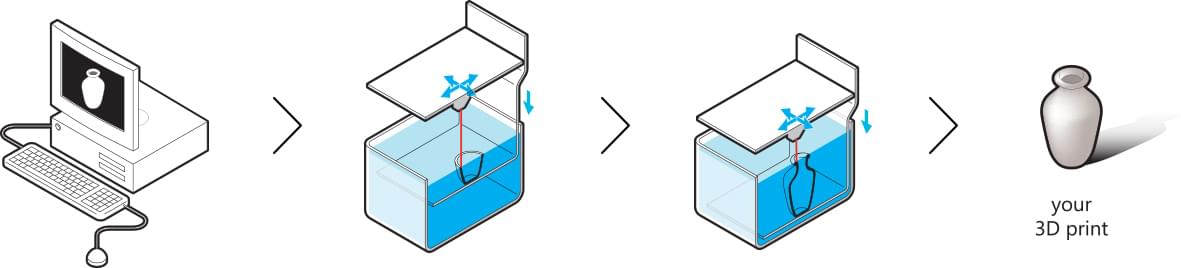

Stereolithography is used to build your design with this material. Starting from a 3D model, a model is built by cutting it into thin layers with specialized software. A support structure is created, where needed, in order to deal with overhangs and cavities.

The process takes place in a large tank and begins when a layer of liquid polymer is spread over a platform. This machine then uses a computer-controlled laser to draw the first layer onto the surface of a liquid polymer, which hardens when struck by the laser. The model is then lowered and the next layer is then drawn directly on top of the previous one. This is repeated until the model is finished. In this way, layer by layer, an object is “drawn” in the liquid by the beam, with the layers being consolidated throughout the process.

When the object is complete, it is raised out of the tank with the supporting platform – much like a submarine rising to the surface of the water – with the excess liquid flowing away. The supports are removed manually after the model is taken from the machine.

Additional Information

- The visibility of the layers strongly depends on the shape or design of the model. For instance, on a curved surface, layers will be much more visible

- Some sides of your standard resin model (depending on the build orientation) will contain small dots where 3D printing support structures were touching the model. These support marks are sandpapered as much as possible, however, sandpapering the model, introduces scratches

- You can also order standard resin with the support structures still attached. It means we have to spend less time on your model during post-processing, which saves you money

- Resins will discolor more from direct UV light than any other material. To slow down discoloration, we recommend varnishing or painting your model

Resin Sample Kit

Includes a sample of High Detail Resin, Standard Resin, Mammoth Resin and Gray Resin.

Additional Materials

We want you to have access to as many 3D printing materials as possible, so you can make the best choice for your project. If you didn’t really find what you were looking for on i.materialise, you might want to take a look at Materialise OnSite. OnSite is our other online platform, mainly used by professionals who need rapid prototyping and manufacturing in an industrial environment.

This means you can additionally find these materials on OnSite:

- Poly1500 : A translucent material with properties comparable to those of PP (polypropylene) and engineering plastics. Being impact-resistant and durable, this material is suited for rigid, functional prototypes in a large range of applications. This material can also be ordered through OnSite's NextDay service, which means your parts will be shipped the same day.

- TuskXC2700W : A white material that is suitable for strong, water-resistant prototypes with ABS- and PBT-like specifications (e.g. parts for water flow analysis and wind tunnel testing). This material can also be ordered through OnSite's NextDay service, which means your parts will be shipped the same day.