11 Fascinating Facts About 3D Printing

If you’re reading this blog, chances are you’re no stranger to 3D printing and know a fair bit about it — but we reckon we can still surprise you with our 11 fascinating facts from the wide world of additive manufacturing.

Every day’s a school day here at i.materialise. We’re always learning something new, and we’re more than happy to share that knowledge with you. That’s why we’ve dug a little deeper into the past, present, and future of 3D printing to come up with the greatest listicle the internet has ever seen.

OK, so we’re exaggerating a little. But what we DO have are some entertaining facts that we think you will enjoy. Let’s take a look!

It’s older than you think

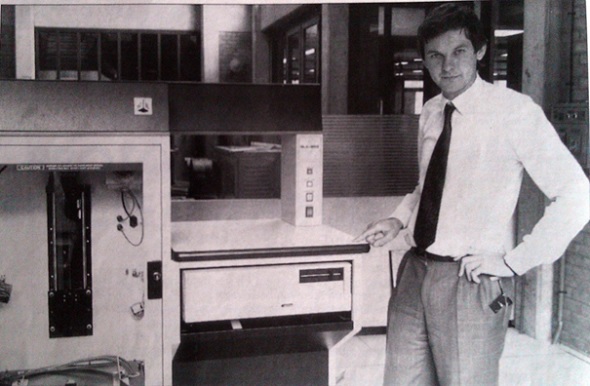

Many see 3D printing as something for the future or consider it a budding technology. Compared to some of the alternatives, that’s arguably true, but it doesn’t change the fact that 3D printing is older than you might think. It started in the mid-1980s when Chuck Hull invented the stereolithography process. That makes it pre-internet old and not much younger than the earliest CD. Nintendo hadn’t even brought out the Gameboy before the first 3D printer was up and running!

To put it in context, look no further than Materialise CEO Fried Vancraen. In 1985, Fried was already creating his own non-computer FDM models before establishing Materialise, one of the first 3D printing companies, just five years later.

It’s not just for prototyping

While 3D printing is definitely an important technology for creating prototypes — many large manufacturing companies continue to use it to test their latest innovations — it’s not limited to a one-and-done design. As the technology improved over the years, it became an affordable option for mass production. Many companies are successfully using AM in full production lines, creating everything from insoles to metal parts.

Of course, it’s not just for the multinationals out there. Independent designers can also bring their creations to life thanks to 3D printing.

It’s called fashion, Brenda

From catwalks to streetwear, we’ve seen some truly inspiring 3D-printed designs over the years. Fashion designers love the freedom that AM brings to their trade, with handbags, eyewear, entire dresses, and other wearables getting the 3D printing treatment more and more regularly. Who knows how long it’ll be before it becomes a high street mainstay?

It lets you print (almost) anything

Many people might not look past plastic when it comes to 3D printing materials, but there are plenty more options to choose from. Just ask the jewelers who use AM to create their latest pieces out of various precious metals!

It gets BIG

Really big. If you thought that printing an entire bike frame was impressive, what about a full-blown mammoth skeleton? With the potential of mammoth stereolithography, size is much less of an issue than it was in the past, making for some exciting opportunities.

It’s on the big screen

Did you know that 3D printing has a starring role in many of your favorite movies? The technology is a great option for a variety of props as they can be created and re-created faster and easier than doing it all from scratch. It’s a great way to showcase the quality and style that AM can offer — just take a look at this gorgeous headpiece worn by Black Panther’s Queen Ramonda, a collaboration between Head Costume Designer Ruth E. Carter and inter-disciplinary designer Julia Koerner.

It prints in layers

Yes, much like onions and lovable green ogres, your 3D-printed part has layers. That’s because additive manufacturing works a lot like your inkjet printer at home. The inkjet printer puts a single layer of ink on top of the page, while a 3D printer adds new layers on top of one another until the object is finished. Take a look at 3D printing in action via the video below.

It helps save lives

Perhaps the noblest use of 3D printing can be found in the medical sector. Surgeons bring 3D-printed guides into the OR or practice on true-to-life 3D models before they even step foot in the room. It is likely to have an important role in making personalized healthcare a widespread reality. Of course, its use in this context is very heavily regulated and should only ever be handled by the professionals, but it’s pretty inspiring, nonetheless.

It can help build ‘soft’ robots

The only thing worse than a grabby robot is a grabby robot that likes to crush things. Luckily, 3D printing can help avoid that. In 2015, Rob Scharff created a soft robotic limb that can shake hands with people and even respond to the firmness of said handshake. Aside from the ability to build new robot friends, advances like this are already helping to develop new prosthetics, make them more accessible to patients, or aid rehabilitation.

It can create moving parts

We’ve seen many beautiful 3D-printed models and gorgeously crafted jewelry, but few designs truly express the potential intricacy of this technology than complex moving parts, like these polyamide puzzles created by David Pitcher. These colorful, twisty, geometric puzzles are truly a work of art.

But that’s not all…

It might soon become 4D printing

3D-printed objects that adapt and move over time? That might just be the future, with a whole host of exciting potential uses. With the right materials, exposure to environmental stimuli such as temperature, light, and water could result in predetermined changes in shape. Whether it’s self-assembling flatpack furniture, new designs in the aerospace and automotive industries, or maybe even something fun like realistic 3D-printed sunflowers, it’s definitely something that we want to keep an eye on.

Feeling inspired?

Get started by uploading your 3D model today!

Recommended Articles

No related posts.