5 Things You Need To Consider When 3D Printing Wearables

Far from its days as a niche technology, 3D printing now accounts for more than 90% of the world’s in-ear hearing aids: and that’s just one example of how this technology is making waves in the manufacturing sector across diverse industries.

In recent years, our parent company Materialise has worked on many eyewear manufacturing projects, in addition to several 3D-printed fashion collaborations and other consumer products. Manufacturing wearable products like eyewear calls for a considerably different approach than non-wearable end-products — and 3D printing is now at a level where it has to address all of these requirements. In the world of wearables, products reflect the identity of different brands, and often one needs to address tough requirements related to both performance and appearance at the same time. So, what goes into the process of using 3D printing to manufacture a product that people will be wearing? Here are the five things you need to consider when 3D printing wearables.

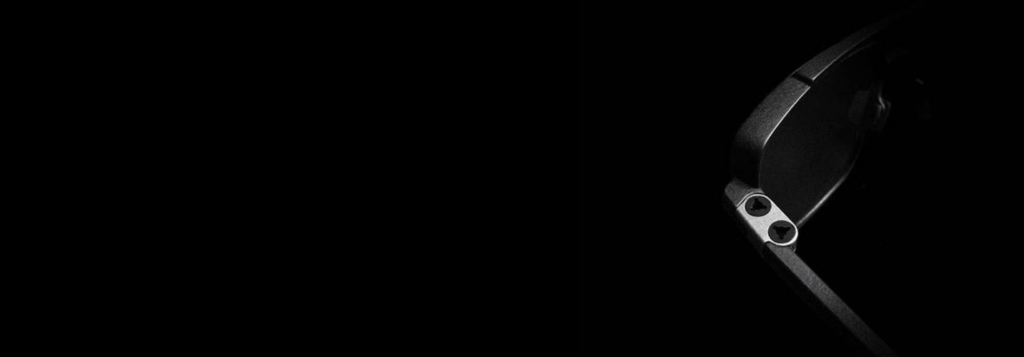

Aesthetics

Consumer products have to appeal to several senses at once. You need functional spectacles that are durable and performant, but it definitely doesn’t hurt if you can also have them in exactly the colors you want and the angles which flatter your features. 3D printing wearables means being able to offer a wide range of colors and finishes, with a quality and elegance that reflects your brand’s identity. And the best thing about 3D printing? You can express your own aesthetic best by taking advantage of the design freedom to create a product that’s stunning even before it’s finished. Which brings us to…

Design

To make the most of the unprecedented level of design freedom that 3D printing offers, start by thinking out of the box. Challenge your existing design norms so you can use 3D printing to its fullest. When Materialise worked with art student Hannah Evans to explore how 3D printing could cross over with knitwear, Hannah found that her design style changed: “You can use materials that just aren’t physically possible on a knit machine, which completely expands the possibilities with knitwear.”

Meaningful innovation

When you’re swept away by the possibilities of 3D printing, it’s important to keep the product’s eventual daily realities in mind. It may be an excellent use of 3D printing, with lightweight structures, optimized volume, and textured surfaces: but judge it first as a product in its own right and then as a case for additive manufacturing. The adidas Futurecraft shoe, with a 3D-printed midsole, illustrates how 3D printing can be used for functional integration and better performance — particularly with regards to personalization.

Customization and personalization

You take freedom of design to its highest degree when you allow for the customization of a product to individuals’ tastes. To several big brands which have embraced 3D printing in the past few months, this has been the key driver: mass customization. The SEIKO Xchanger sports eyewear collection is modeled entirely around the idea of customers being able to put together their own perfect sports glasses by choosing each element of a modularized frame. That idea is taken even further by customized insoles, which are based on the end user’s dynamic gait analysis to make sure they fit exactly to the wearer’s feet. If your product is based on the wearer’s measurements, see how customization could add functionality for the end-user. As for personalization from the supplier’s side, you can explore the possibility of offering various textures or aesthetical options.

Performance and durability

Selecting the right material for your wearable is essential — and so is the right finish. For eyewear, jewelry, and other wearable consumer products, skin contact will be a constant reality of the product’s usage. Exposure to a wearer’s skin can affect the product’s finish over time, potentially making colors less vibrant or surface treatments less effective. Environmental wear and tear are inevitable, but a good finish can reduce the surface porosity and protect it from changing colors due to UV light or acquiring stains and marks. To ensure the best material performance for your product, you need to ensure that your materials are durable, perspiration-proof, UV-resistant, and stain-resistant — in addition to being skin contact-safe. That’s what Luxura, our consumer-grade finish, does. Because once you have a great product, you want it to stay that way.

Ready to 3D print your own projects?