10 Examples of How 3D Printing Is Changing Consumer Products

Everybody’s talking about 3D printing: 3D printed implants, 3D printed cars, 3D printed houses. While the media likes to focus on big projects, a large part of this new industrial revolution is happening in small design studios, backyard sheds, and start-ups by makers, designers, and other creative minds. In this post, we show you some examples of how 3D printing is changing our everyday consumer products.

3D printing consumer products: 3D printed “Necklace Tree” and “Ring Tree” by jewelry brand blueberries

A New Product Trend: 3D Mass Customization

Without a doubt, mass customization is one of the main ways in which 3D printing will change the face of consumer products. With easy-to-use online apps, everyone can create unique, personalized items:

- In 2014, Ilja Laurs co-founded the company Toyze, the first app store for 3D printed customizable game characters. From smartphone to shelf, it allows gamers to 3D model and print their favorite game characters. Toyze aims to democratize and stir up the toy market by offering game developers of all sizes the opportunity to extend their branded characters to custom merchandising: “You will be able to print your own Superman. And nobody else in the world will have exactly the same toy”.

- Another example that follows this this path is the Belgian start-up Twikit. Martijn Joris and his colleagues launched their first app to build customizable trophies back in 2013. The team created an online platform through which anyone can personalize and order their very own 3D printed award. No 3D modeling skills are required, no software needs to be downloaded. Over the years, more customizable items such as jewelry, fashion, and interior design items were added: “We see ourselves as an exponent of the ‘maker’ era, with a strong consumer-oriented point of view. We want people to tweak and build products in the easiest way possible. Everybody can tweak and customize designs using our intuitive configurators.”

Accessibility and a variety of options are the keys for success: shape, size, fonts, and texts need to be easily customizable by the users, allowing for truly unique and personal products.

Customizable 3D printable game character based on “Cut the Rope” in the Toyze app

Customizable 3D printed lamps from Twikit

The Only Entry Requirement: A Head Full of Ideas

3D printing lets everyone become a designer. Thanks to online services like i.materialise, you do not need your own printer or production facility anymore. All you need is a creative mind:

- Caroline Das is a young but irrepressible architect who discovered a passion for fusing architecture and fashion during her studies. Driven by the desire to expand the boundaries of these two areas, she co-founded her own fashion brand (DAMN) in 2011: “We were architects, not jewelry designers, but we knew how to design in 3D.”

- Another good example is shoe designer Katrien Herdewyn, who has a background in electrical engineering, material sciences and nanotechnology. She decided to blur the line between these fields and started experimenting with 3D printing in her shoe designs as well. She contacted 3D modeler Frederik Bussels, who “translated” her designs into 3D models. Together they created stunning pairs of high heels and explored the endless possibilities of 3D printing.

- Peter Donders is another prime example of someone working with the limitlessness of 3D printing. With a background in furniture design and craftsmanship, and knowing how to use 3D modeling software, Peter created his own jewelry creations with i.materialise: “I didn’t really plan to make a 3D printed jewelry collection. Someone asked me to create something small and then my plan got a little out of control: I ended up with an entire collection of 3D prints.”

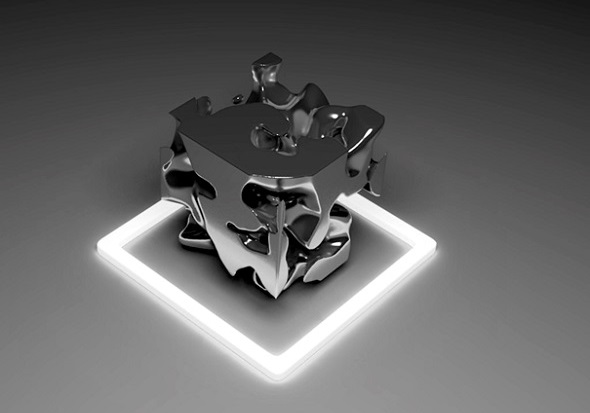

- Scientist and artist Frederik De Wilde uses the possibilities of 3D printing to his advantage when it comes to creating innovative pieces of art. 3D modeling software enables him to create objects that wouldn’t have been possible using traditional techniques. For example, he created art out of a 3D model of a Belgian coal mine system, and a 3D model that was generated using a live data feed from devices measuring quantum fluctuations.

As pointed out previously: a head full of ideas is the only entry requirement to using this technology. Your background or field of study is not essential to your success. All that counts are innovative, creative, and smart projects.

3D printed titanium fashion item from Caroline Das and her DAMN label

3D printed high heels by Katrien Herdewyn and Frederik Bussels

3D printed jewelery items by Peter Donders

Frederik de Wilde’s 3D model was generated by using a live data feed from devices measuring quantum fluctuations

3D Printed Variety: From Scale Models to Jewelry, from Plastics to Titanium

Basically anything can be 3D printed these days: plastics with interlinking parts, transparent material, gold, silver, and bronze. Even materials such as ceramics or titanium can be printed. This means that 3D printing is not limited to one field or one profession – its variable use is one of its biggest benefits:

- In 2012, Zbyněk Krulich co-founded the 3D printed jewelry brand blueberries. Zbyněk’s work takes simple, minimalist ideas to new levels by bringing an air of strength and sophistication to them. The latest collection of jewels was made of light and flexible nylon. More recently, jewels made of transparent resin, stainless steel, silver, and gold were added to the collection.

- German scale modeler Guido Mandorf started to use 3D modeling software back in 2011. He designs trains and trams himself, orders them in Prime Gray material, and finishes them with a beautiful paint job. No more dependency on other people or companies. 3D printing gave Guido all the tools he needed to create beautiful and realistic models in plastics.

- Industrial Designer Elise Luttik from Amsterdam, founder of design studio eli5e, creates stunning interior design objects. From Polyamide to Ceramics, she simply chooses the best fitting material for each project: “I think 3D printing gives lots of freedom compared to the more traditional mass production methods. In the near future, I would love to make some 3D printed designs made from scented, fluorescent or recycled materials.”

3D printed “Ring Tree” by Zbyněk Krulich and his blueberries label

Hand-painted prime gray tram model by Guido Mandorf

Ceramics 3D print “Edgy” by Elise Luttik

Designing in a File: New Ways of Sharing Products

Designing on a computer and putting ideas into virtual files also changes the way we create products. Newer and better products can be designed in a world where people work together to make great things happen.

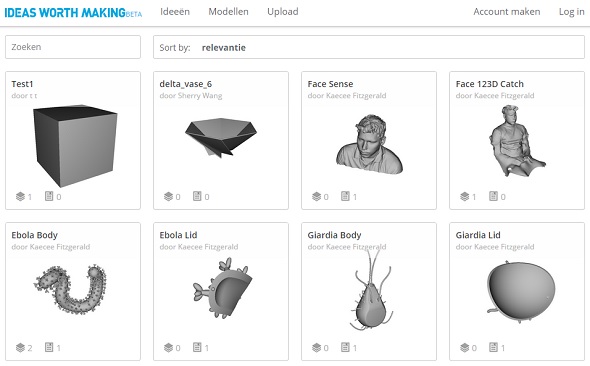

- Christophe Fauconnier, founder of innate motion, believes that “winning by giving is what is going to drive new value networks and will make a difference.” That’s why Christophe is helping to create a new online sharing platform called Ideas Worth Making. This platform enables people to share ideas and designs to help others. Examples include tools for educators to enhance their teaching, applications for the blind to better interact with and understand the world around us, and devices for people with motor difficulties to make their life easier.

Ideas Worth Making: Turning smart ideas into 3D printed reality.

Putting It All Together: 3D Printed Consumer Products

3D modeling and 3D printing is already changing our consumer market little by little. Mass customization, once a complicated and expensive idea, has become a reality. The entry requirements for 3D printing are low: no production facility, not even printers are needed for designers. An online printing service is all you need. These services also give designers and makers the freedom they need: changing the size or material of an object is now just a matter of a few clicks. Additionally – if desired – designers can share their design to get input from others to make products even better or to help others with similar design challenges. All of these circumstances are driving this new industrial revolution that is going to change the consumer products of the future.

3D printing brings your virtual designs to real life. If you would like to print your 3D designs as well, nothing is easier than using our online 3D printing service. If you’re new to the world of 3D printing check out our creation corner for free 3D modeling software and professional designers who can help you to turn your idea into 3D printed reality. Whether you’re a novice, a 3D printing design startup, or an established business looking to venture into 3D printing for customizable products, we have something for everyone with an eye for design and a head full of ideas.

Recommended Articles

No related posts.