Columbia GSAPP Saturated Models 3D printed: Soft Surface

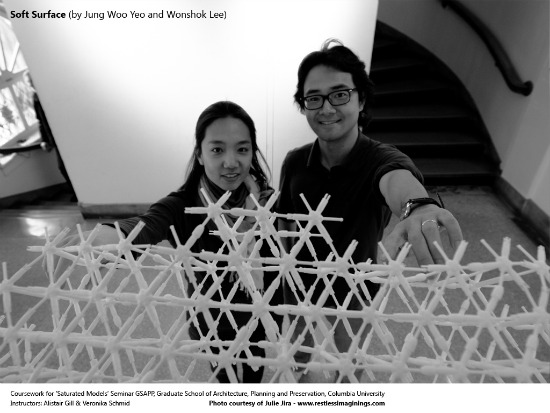

Alistair Gill and Veronika Schmid held a Saturated Models seminar at Columbia’s Graduate School of Architecture, Planning and Preservation. During the seminar the Master’s students explored 3D printing and created 3D printed objects. i.materialise made the resulting 3D prints. This is the third interview with a team of participating architecture students, Jung Woo Yeo and Wonshok Lee, and their project Soft Surface. The first two interviews can be found here and here.

1. Who are you? We are passionate architectural designers who just completed a Master of Architecture program at Columbia University in the city of New York.

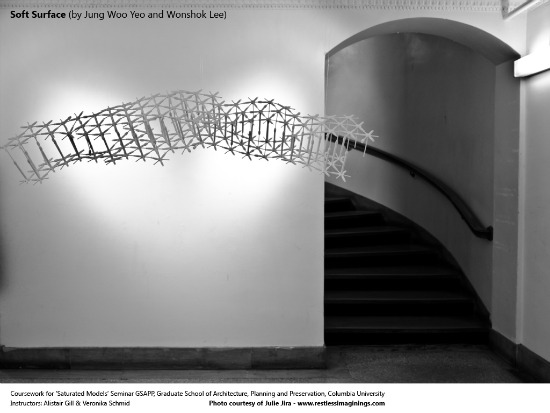

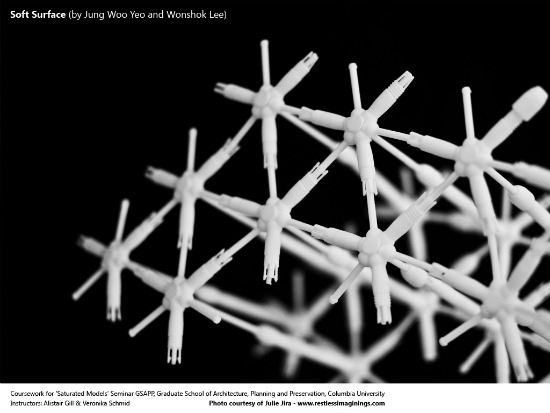

2. What is Soft Surface? Soft Surface is an undefined object which is composed of two basic modules that together are repeated to create a network of nylon frames. The object changes its state from rigid to semi-rigid to flexible by controlling the relationship between frames even though each frame is stiff. This object is also made flexible in shape and size by adding or changing the combination of modules. It looks solid at first glance but is actually similar in consistency to soft dough. This project is an experiment in flexibility and unpredictable transformation, and also a question of perception. Soft Surface is a hollow object, but it is perceived as mass. It is a combination of lines but it is perceived as surface.

The function of Soft Surface is not determined. It can have multiple functions. This object can be used as a light cover or window shade in small scale, as a ceiling, or wall in large scale. Anywhere a surface is needed, can be a potential site. Taking advantage of the quality of this object, these architectural devices will have unique porosity and flexibility.

3. Why did you make it? There was a valuable opportunity for us to conduct a 3D-print project in the ‘Saturated Model’ course at Columbia University, taught by Veronika Schmid and Alistair Gill. We took the chance.

4. What software did you use to make it? Rhinoceros. To build the sophisticated model in detail, Rhinoceros was the right choice for us. Rhinoceros was also what we were used to working with, which allowed us to model quickly.

5. What was the process by which you came to your design? Our idea started from a question ‘is it possible to make a soft wall?’. Then, ‘how can we make a soft object with rigid frames’ was a question that followed. By considering objects from various perspectives, we reached the idea that should be a hollow object with frames but perceived as a solid mass. Questions concerning flexibility led us to more sophisticated flexibility, like changing the state of the object from rigid to soft and size and shape at the end. To realize these ideas, we studied with physical models (made of plasticine clay) and developed digital models. We created two basic modules that are organized with seven frames respectively. We generated a unique joint to permit the free movement of these frames and details for assembly and changing states. We tried new methods in 3d printing technology at every stage and it led us to the innovative result we did not imagine.

6. Will you be using 3D printing more often in the future? Definitely.We experienced the great potential of 3D printing with this project. We explored innovative ways from the early stage of design through design development to the constructing model stage. It was a kind of a paradigm shift in design. We believe this technology is opening new horizons in design from small scale objects to large scale architecture. We hope to have chances to further examine the potential of the 3D printing.

Photos are by Julie Jira.