Five Top Tips To Perfect Your 3D Printing Files

When the time finally comes to hit that hallowed upload button and get your 3D printing project underway, you want to make sure your design follows every rule and is ready to go. While our team is always here to double-check every submission and flag any errors, following our five top tips will help ensure every file is printable and maybe even cut down on some of your costs while you’re at it.

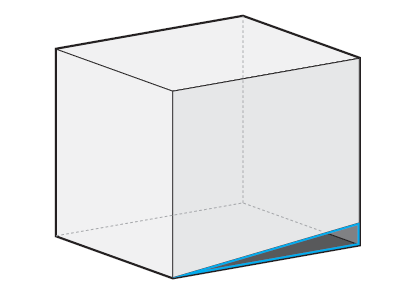

#1: Make your model watertight

For your file to be ready to print, all of your surfaces must be connected without any gaps in the sides. So, before you submit your design, look over your model and ask yourself one question: if I were to fill it with water, would it flow out? If the answer is yes, it’s important to close it, as shown in the example below. This process is also known as ‘creating a manifold model’.

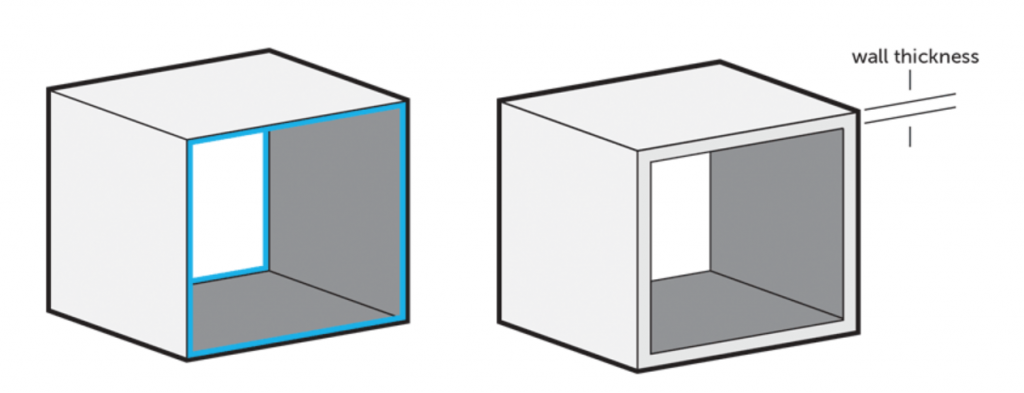

#2: Add wall thickness and volume

Every surface of your 3D model must be assigned a wall thickness. Wall thickness is simply the distance between one surface of your model and its opposite sheer surface. When using your 3D modeling software, it is possible to design so-called paper-thin surfaces for visual purposes (i.e., for games) that do not feature any information about their thickness. However, 3D printers need to know how thick you intend your object’s wall to be (or if you want to print a completely solid model).

The minimum wall thickness primarily depends on the material you choose. You can learn how to select the perfect wall thickness for your 3D print here.

#3: Set the size of smaller details

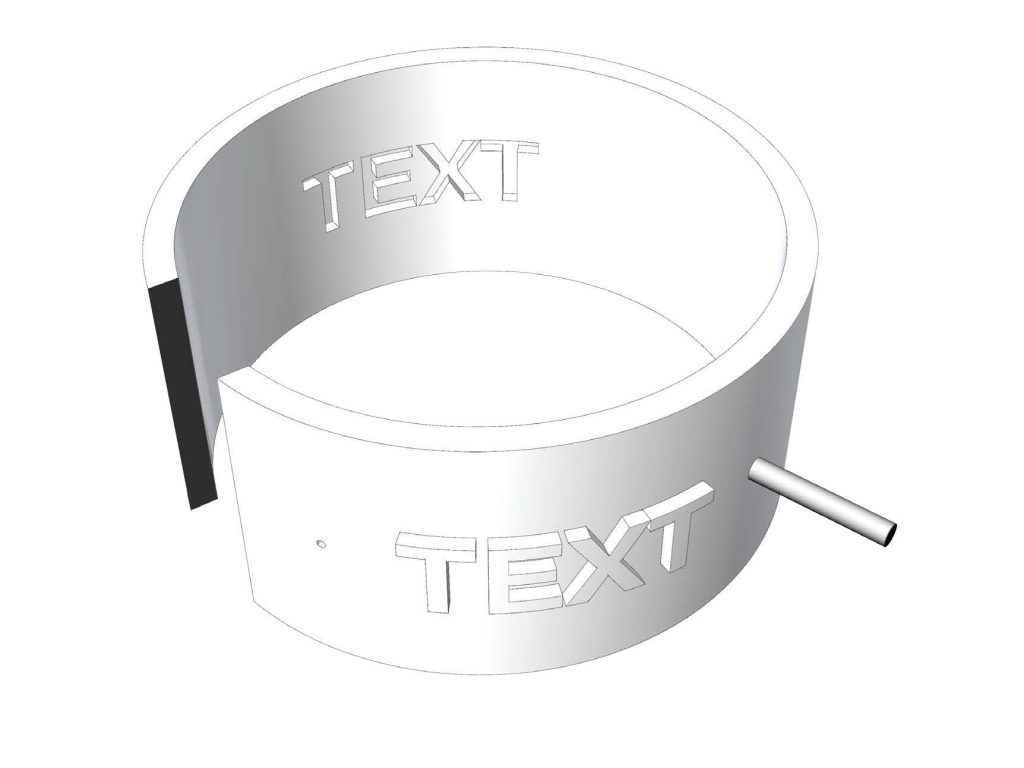

The details, or the small decorative parts like embossed or engraved text, need to be of a certain size, or they will not appear on the printed object. The minimum size of the smallest features of the design depends heavily on the material of your choice. That’s why you need to start by carefully reading through the design guide of the material of your choice.

This is especially important if you intend to add embossed or engraved details such as text. Sticking to the minimum detail size will make sure that everything is as legible as you intended.

For your text to be legible, it’s important to make sure it is large enough for the machine to read and print.

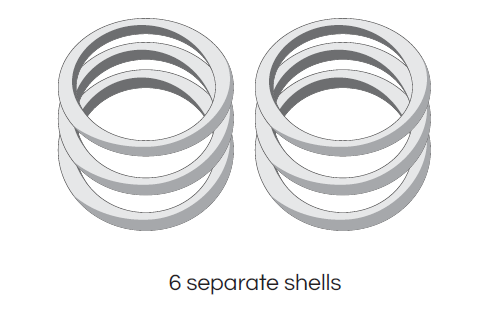

#4: Upload grouped models correctly

One of the main reasons for an order to be canceled is so-called grouped models, where one separate part is repeated several times within the same file — imagine a stack of disconnected rings, if you will. Instead, it’s important to upload each design individually. To help make this easier, you’ll enjoy a volume discount if you need more than one of the same design. Alternatively, you can consider adding a grid container to your work if you’re printing with Polyamide or Alumide.

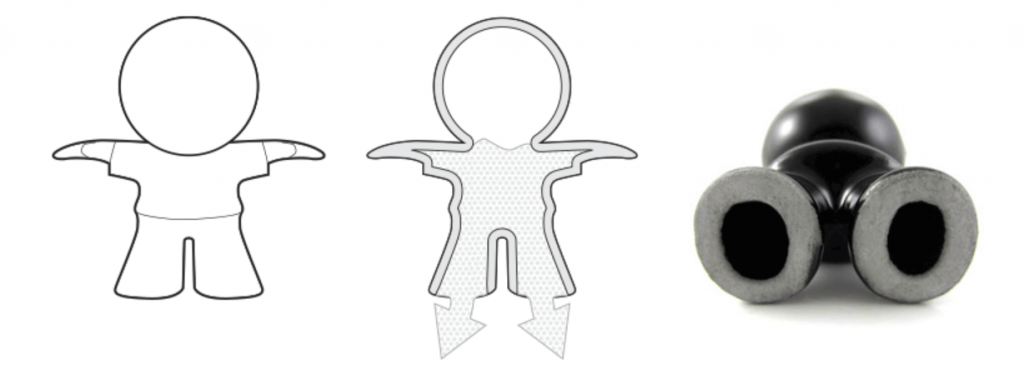

#5: Hollow out your model (and give it some ‘escape holes’)

While there are definitely benefits to creating a fully solid model, such as added strength and durability, using more material will understandably mean your design is more expensive. By creating a hollow model, complete with ‘escape holes’ to remove any excess printing material, you can drive down the cost of every item you print. Take a look at the example below for reference!

The less material your model uses, the more affordable it will be. Adding these escape holes can help!

It’s time to start printing!

That’s it from us! Now you know our five top tips, we’re sure your designs will be better than ever. If you’re still on the hunt for some more advice or inspiration, make sure to check out our official i.materialise forum, download our new Beginner’s Guide, or learn more about the types of materials and 3D printing technologies we have at your disposal. And once you’re ready to get started? You know exactly where to find us.

Recommended Articles

No related posts.