Rolls Royce is going to 3D print aircraft engines

The Merlin Project is a €7,120,000 EU research project that will be conducted by Rolls Royce in conjunction with other aircraft engine manufacturers. The aim of the project is to over the course of three years explore the use of 3D printing to make aircraft engines in order to reduce their enviornmental impact. The project aims to use 3D printing “to allow environmental benefits including near 100% material utilisation, current buy to fly ratios result in massive amounts of waste, no toxic chemical usage and no tooling costs, to impact the manufacture of future aero engine components. All of these factors will drastically reduce emissions across the life-cycle of the parts. …. Light-weighting, and the performance improvement of parts will result in reduced fuel consumption and reduced emissions….Impacts will include the development of high value, disruptive AM technologies capable of step changes in performance which will safeguard EU companies in the high value aero engin

Hella Jongerius” 300 unique ceramic vases

Celebrated Dutch designer Hella Jongerius has an obsession with imperfection. She developed 300 unique vases to acompany special editions of her new book, Hella Jongerius:Misfit. The video below runs you through the entire production process of the vases.

We often think of 3D printing as the de facto technology for developing unique objects. Hella”s vases however are caramic and made by the venerable Royal Tichelaar Makkum (the Netherlands oldest company, founded in 1572). I think it is interesting to watch designers experiment with unique, with designing something that will be result in many different items that somehow stay well within the designer”s intent. Mr. Tichelaar hits the nail on the head in the video, “its not designing, its creating. Its exploring, its experimenting. Sometimes its very nice and somethimes you think its a bit strange, but its always beautiful. It always has a value, which you would like to cherish.” This is the best explanation I”ve heard yet of

i.materialise will be offline on the 27th

We”re sorry to have to inform you that the i.materialise website will be offline on the 27th of December. We will be offline from 6:30 CET in the morning until 16:00 CET in the afternoon. During that period there will be major electricity works going on inside the Materialise HQ. We know this is a very long time to be offline and apologize for any inconvenience.

Image by Wonderlane, Creative Commons, Attribution

The Year of 2010 in 3D Printing: An Overview

To my abject horror there was no “year in review” for 3D printing. I decided to right this wrong and produce this one. I’ve tried to be as unbiased and inclusive as possible. If I’ve missed something, feel free to point it out in the comments and I’ll add it. 2010 was a miraculous year in 3D printing. Thousands of people have bought and made RepRaps and Makerbots en tens of thousands use 3D printing services such as i.materialise to 3D print their own creations. (more…)

Portal inspired Bookends on Thingiverse

We were thinking of some fun things to do with our Design Your Own Bookend. Because some of us are obsessed by Portal & Reddit, we had seen this awesome Portal Bookend on Reddit. So we asked Nicolas de Jaegre to make a Portal (and Reddit) inspired bookend fit for 3D printing. We put the 3D printing files on Thingiverse so you can download them and play with the files should you want to. Now everyone with a 3D printer can 3D print their own Portal inspired book ends. Enjoy!

.MGX opens world”s first store for 3D printed goods

.MGX, Materialise’s high end design label for 3D printed furniture and lamps, just opened the world’s first physical store for 3D printed goods. The .MGX Flagship store is in Brussels” exclusive Sablon district. At the store people can look at and explore .MGX’s lighting and other collections. In the future .MGX will showcase new designs and exhbitions by its designers in the store. You could obtain .MGX items in other design stores world wide previously such as New York”s wonderful Moss but this is the first dedicated .MGX store. It is also the world’s first store dedicated to 3D printed items, we’re guessing it won’t be the last!

The .MGX Flagship Store is located at Rue Joseph Stevensstraat 31 – 1000 Brussels (Zavel/Sablon).

UPDATE: We take you inside the .MGX store here.

The Rhino & i.materialise 3D printing Design Challenge

Together with McNeel we would like to stimulate Rhino artists & designers worldwide to get the most out 3D printing. We both want to encourage stimulating, innovative and creative 3D printed products that are “Future Forms Today.”. That’s why we’re jointly announcing the Rhino & i.materialise 3D Printing Design Challenge and making over $1000 in prizes available to you.

What can you win?

- First place wins $500 in 3D printing & an i.materialise Appear lamp.

- Second place wins $300 in 3D printing.

- Third place wins $200 in 3D printing.

How will we judge the contest?

McNeel Europe & i.materialise team will jointly judge the contest. We will be looking at people who show the power of Rhino & 3D printing in their designs. We will be looking at designers and artists that can make “Future Forms Today.” We will consider the originality and presentation of the design. We will also take into account if you use maximize the power of 3D printing in your product. So is your pro

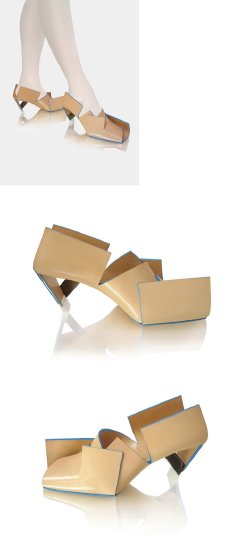

i.materialise interviews groundbreaking shoe designer Marloes ten Bhömer

In my mind there are only two shoe designers that are really revolutionizing shoe design. One is Rem D Koolhaas of United Nude and the other Marloes ten Bhömer. Both a are using cutting edge materials and design to make shoes contemporary and amazing again.

Marloes ten Bhömer is a lauded designer who has been called “one of the most promising designers of her generation”. She uses innovative production techniques, new materials and completely different ways of looking at form & function to redefine footwear. Marloes’ Rapidprototypeshoe, pictured below, is a great example of using 3D printing to create wearable footwear. We interviewed Marloes to find out more about her beautiful shoes.

Joris Peels: Why use 3D printing?

Marloes ten Bhömer: 3D printing is interesting to me on various levels.

It’s quite difficult to convince manufacturers to produce parts for products that are outside their usual industry. In my case I use production methods and materials that are rarely o

The Google SketchUp lamp Challenge winners 3D printed

We wanted to share the winning designs of the Lamp Challenge we conducted together with Google SketchUp. We think that the four lamps we chose look incredible 3D printed. What do you think? Which one is your favorite?

If you”re a designer you can go here to learn how to 3D print your own lamp. Not a designer? No problem. You can individualise your own Appear lamp here.

Congratulations to the winners and thank you for everyone that participated. We enjoyed all 55 of your designs and are really very happy with the results of the competition.

Special Jury Award for the Amazelight by Oscar Rottink.

Third place for HD Studio Lamp by Zach Hines & Oliver Dibrova.

In second place: Parasite by Paradox.

In first place, the 3D Maze by Corre.

i.materialise, mi logo es su logo

We are in the process of rebranding i.materialise. In the months to come you will see many changes in the way we present ourselves to you. As a part of this we are today unveiling our new logo.We thought long and hard (together with brand identity agency, thepubagency) about how we would explain ourselves to the world. We really wanted a logo that would encapsulate the fact that we are your 3D printing service and manufacturing partner. We know that we are the sum total and expression of your creativity and we wanted to make this clear at all times.

For this logo we will do something unique & original together with you. We will, unlike other companies, not have one symbol as a logo. Our logo will not be the same. Our logo will change. We will even use many different versions of our logo at any given time. The new i.materialise logo is simply the word “i.materialise” written by you. You can simply take a few minutes to hand write and then upload a logo to us here. We will col