3D Printed Shoes: Combining 3D Printing in Plastics & Steel with Traditional Craftsmanship

Meet Eric Meijer, designer of a new collection of 3D printed shoes. His innovative approach: combining 3D printed plastics, 3D printed steel and traditional craftsmanship for creating one-of-a-kind high heels. We spoke with the Dutch innovator and took a look at his latest designs.

Hello Eric, please tell us a bit about yourself.

My name is Eric Meijer. Most of the year I live in Spain, enjoying an inspiring view of the Mediterranean Sea. I have been a commercial diver since 1984, working in the Dutch sector of the offshore industry.

… and as a 3D designer! Could you present us your latest projects of 3D printed shoes?

I currently have three unique pairs of wearable concept shoes and one pair that needs a makeover before it is ready.

Party Starter: These leather shoes boast a bottle opener feature, and have a lattice at the tip for cooling and decorative purposes. The stainless-steel heels and alumide lattices (front) are 3D printed.

Party Starter by Eric Meijer

Mixed Emotions: These leather shoes have the ability to change looks endlessly because of the heel decorations. The stainless steel heels and the heel decorations of dyed polyamide are 3D printed.

Mixed Emotions by Eric Meijer

Space Invader: These hybrid sandals are finished with leather straps. The leather insole and rubber outsole make these shoes very comfortable. The shoes are sleek, strong and flexible. These polyamide shoes are 3D printed almost in their entirety.

Space Invader by Eric Meijer

Galactic Star: This over-the-top shoe is not comfortable enough to wear at the moment, it needs some more tweaking. This shoe is 3D printed in polyamide as well.

Galactic Star by Eric Meijer

How did you get the idea of starting these projects?

I had some ideas that didn’t exist on the market so I thought it would be nice to design them myself. After a search on the web I found the website of Rosanne Bergsma, a shoe designer who lives in Arnhem. She makes prototypes, one-offs and has her own shoe-line. She used her craftsmanship to help me realise my designs and make them look as good as they do now.

Rosanne working on the finishing touches.

And how did you get the idea of using 3D printing to achieve this?

In 2010, I visited a presentation and workshop by i.materialise at the University of Applied Sciences in Vlissingen. This spurred me on to materialise my own ideas and dive into digital sculpting.

Where do you get your ideas from and how do you typically start a new project?

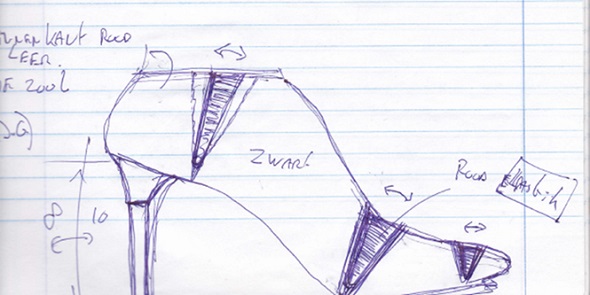

Ideas always come and go so I have to capture them as a sketch or as a written note. Afterwards, I sit at the computer and work things out.

It all starts with a hand-drawn sketch.

Which 3D modeling software did you use for creating the shoes?

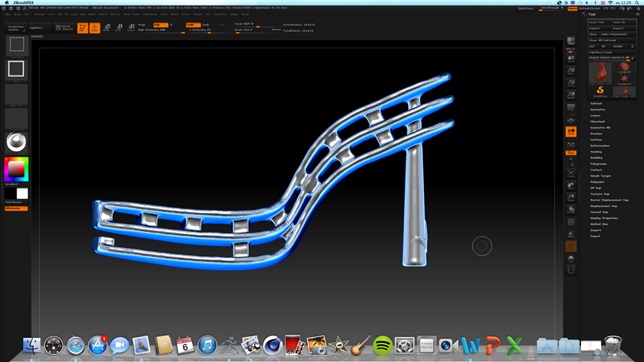

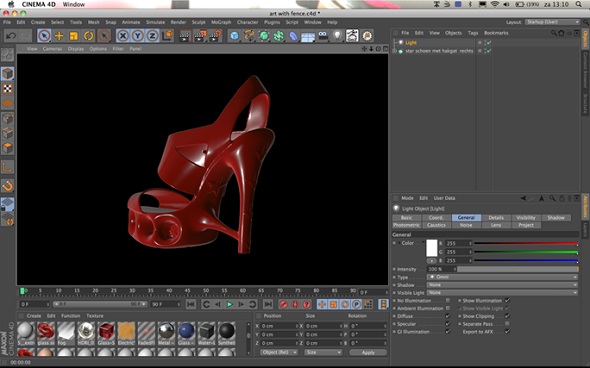

I use Cinema 4D and ZBrush because they work seamlessly together. ZBrush is my favorite software. It has an excellent free learning platform called ZClassroom. They also give fast feedback if you have any questions. It is great value for money, and in the ZBrush gallery you can see mindboggling work from other 3D artists.

Eric designs the shoes in ZBrush…

… and Cinema 4D.

Which 3D printing materials do you use and why?

Polyamide: for the white shoes and the red decoration on the leather shoes. I enjoy working with polyamide because i.materialise has a priority service which ensures fast delivery and makes it easy to use for testing and prototyping.

Stainless Steel: for the heels on the leather shoes. I made this decision after an attempt with polyamide and ABS which wasn’t strong enough to carry the weight of a person.

Alumide: I picked this material for the lattices in the Party Starter model. Actually, I would have liked it better if it was in high-detail stainless steel because then it would be shiny just like the stainless-steel heels but the building box couldn’t cope with the size of the lattice.

3D printed stainless steel heels and polyamide heel decorations.

In what way does 3D printing help you in creating these objects?

If 3D printing didn’t exist, I would be a frustrated person with a lot of weird sketches and ideas.

How do you post-process your 3D printed shoe?

I did the following four post-processing steps:

– Sanding the shoes with 3M flexible diamond pads.

– Glue the insole and shoe sole on. This makes the shoes more comfortable.

– Glue the leather straps on the inside of the shoe.

– Glue the heel caps in for protection and comfort.

Post-possessing the 3D printed high heels with diamond pads.

Attaching leather straps to the 3D printed shoes.

What do you think the future business model of manufacturing 3D printed shoes will be?

I think that when 3D printers become faster and cheaper you will reach a point where this kind of business will get profitable.

I hope that the production process for 3D printed shoes might look something like this in the future: the order comes in, and the shoes get printed right away. Assembly could be done in less than 10 minutes and the shoes are ready for shipping. The big advantages of this will be no more need for stock, or expensive machines for assembly.

Do you have plans to manufacture or sell your shoe designs?

I have a patent on the heel decoration and a patent pending on the flexibility of the 3D printed Space Invader shoe. I think that creating new designs is the best way forward for me. If my shoes rake up a lot of positive feedback, I would certainly consider taking them into production, but this would also depend on the interest of third parties.

For further questions you can contact the Eric at info@eyecandyshoes.com, visit his website, or visit his Tumblr and Facebook pages. If you want to learn more about 3D printed footwear, our blog post “How 3D Printing is Changing Racetracks and Runways” is just what you’re looking for.

Recommended Articles

No related posts.