Get To Know Our Two New Multi Jet Fusion Polyamide Finishes

The 3D printing world is constantly evolving with new material launches, and we’re excited to announce even more additions to our finishes lineup. In fact, we’re doubling our finish offerings for Polyamide, a Multi Jet Fusion material option! Along with our current finish options of natural and color dyed, you can now make each of these finishes polished. Wondering what you can expect with these newcomers? Let’s dive into it!

Polished natural

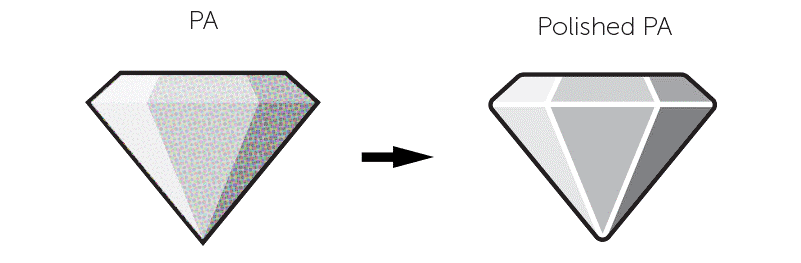

The steps for the polished finish follow those of the natural finish, plus a few new additions, to create a sleeker surface texture. Just as is done with natural parts, once the piece is printed, loose powder is removed before sandblasting. In this case, in order to achieve an even finish, the part is then mechanically smoothed using a tumbler and pebbles. As the tumbler vibrates at a high frequency, pebbles rub up against the part, thus polishing the outside further. The end result is a sleek, gray appearance.

Polished dyed

The steps for this finish are just as you would guess. The methods used for the polished natural finish explained above are combined with the color dyed option. After the post-processing steps to smooth the part, it is then submerged in a bath containing a black color pigment. Make sure to plan in sufficient time with this finish because it adds one working day to the lead time.

Polished design guidelines

Make sure to follow the design guidelines mentioned below for your polished Polyamide orders so that your design prints successfully the first time!

- A minimum of 1 mm wall thickness is required throughout your model.

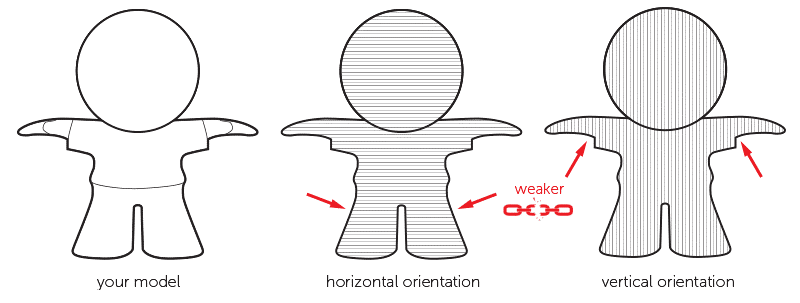

Although we carefully place and orientate your models in our printers to minimize “weak points” created by the layered buildup of your model, certain elements of your design may be more sensitive to the impacts of the polishing stones than others. Therefore, we suggest adding some extra wall thickness if your design can allow for it. Polishing is not advised when your model has tiny details like pins because they will break off during the polishing process.

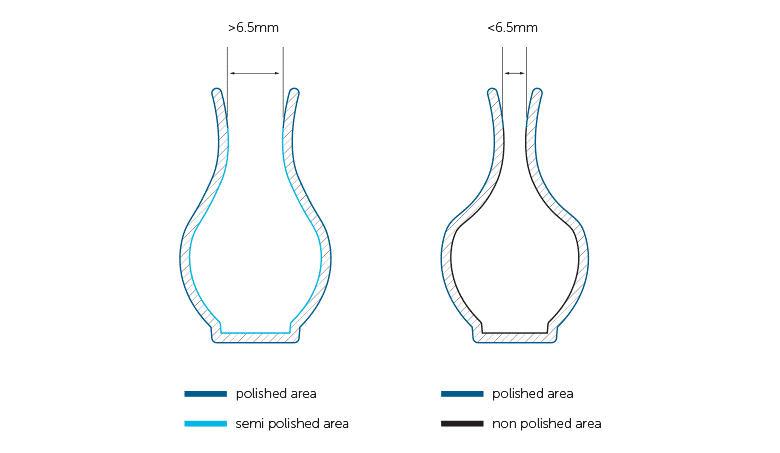

- We recommend that any openings to be polished have a minimum diameter of 6.5 mm.

Because of the size of the polishing stones, they can easily get stuck inside small holes. We recommend that any holes have diameters larger than 6.5 mm to avoid stones getting stuck inside your model. Also, note that the inside of your model will always be less polished than the outside — in fact, your model will not be polished at all on the inside if the holes are smaller than 6.5 mm because the stones won’t be able to enter.

- Edges will be rounded off

If your model contains sharp edges, these will be rounded off. Rounded corners and smooth transitions between surfaces will have a higher degree of polishing than sharp edges. Polishing will take 0.1 mm of material off of your model, so add extra wall thickness to avoid any problems.

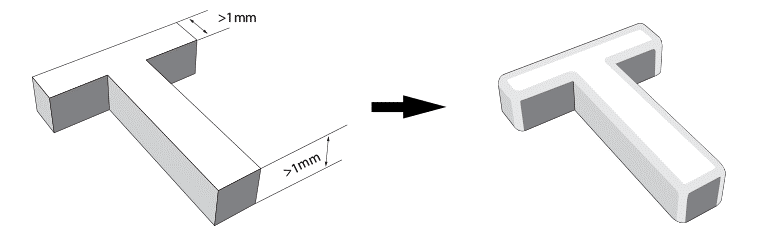

- Increase embossed and engraved details by 1 mm

The polishing stones tend to wear away embossed details on your model. Raise these details by at least 1 mm, otherwise they may disappear during the polishing process. Engraved details are less of a problem because, in most cases, the stones won’t be able to reach the inside of the engraving; however, the edges may still be affected. To be on the safe side, make sure your engravings are deeper than 1 mm.

How to print with Multi Jet Fusion

HP Multi Jet Fusion (MJF) is a direct 3D printing method that utilizes powder, fusing agents, and detailing agents. A powder bed is heated throughout to begin, and then a fusing agent passes over specific areas of the bed where the powder will be melted together to create the part. The detailing agent is also jetted around the contours to improve part resolution. While lamps pass over the surface of the powder bed, the fused material captures the heat and distributes it evenly. We offer two materials to be used with this technology: Polyamide and Rubber-like.

Interested in trying out our new finishes for your next project? Order today!

Keep in touch with our latest launches and news. Subscribe to our newsletter and stay up-to-date.

Recommended Articles

No related posts.