The Need for Speed: Navigating the Urban Landscape With a 3D Printed Electric Longboard

Sune Pedersen has invented a whole new way of getting around. With the ambition of changing the future of urban transportation, this software engineer from Copenhagen has used the power of 3D printing to create an innovative range of urban transportation vehicles for mobility-impacted people.

To achieve this, Sune launched his own startup Faraday Motion and started creating an open-source platform for personal electric vehicles. Faraday Motion is based on advanced but simple-to-use hardware, software, and 3D printable models. Their technology enables anyone to make and use their own compact electric vehicles.

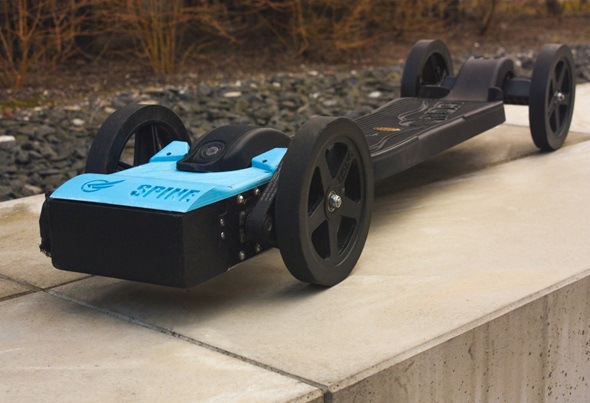

Together with his team, Sune has already brought to life an incredible 3D printed electrical skateboard called the Spine that can hit a top speed of 19 mph (30 kmh). Their newest project, the Hyperboard R2, can even reach 40 mph (65 kmh).

All of this was reason enough for us to meet Sune and take a look at his project.

Sune Pedersen on the Hyperboard R2, a 3D printed longboard.

Hi Sune, could you tell us a bit about yourself?

My name is Sune Pedersen, I’m 38 years old, have a background within software and live in Copenhagen. Faraday Motion started as a kind of experiment as I was looking for a solution to get around more conveniently in urban settings after partly losing mobility in my knee after an accident. Since mid-2014, this has developed into Faraday Motion, a small company and team, but with a big vision of changing the future of mobility with an open-platform approach.

What drives you and your team at Faraday Motion?

We all love making things, tinker with new technology and use software to simplify the complex world we live in. We believe that we can utilize the modern social web to get the best creative minds to collaborate on essential building blocks that will empower everyone to create the personal electric vehicle of their dreams.

What is this 3D printed electric skateboard that you’re working on? What makes it so special?

The Spine is an entry-level electric skateboard, and the Hyperboard R2 is the world’s most advanced electric skateboard. We have built an extreme version that will go 65+ kmh and if driven normally, has a range around 30 km. Our boards are all based on Onda Motion’s Core longboard for now, but we are working on a more modular approach to building more diverse types of vehicles. Our platform basically enables you to “put wheels on your smartphone/arduino” and uses a range of sensors to make it do cool things with software. It is basically a driving robot.

For us it is important that our customers can change and modify the parts that they like. This is unlike typical consumer products where modification or changing functionality is not possible or very limited.

We have released our 3D files online with a non-commercial license. This enables everyone with access to a 3D printer to start printing our boards right away for non-commercial purposes. We use open-source hardware, and our electronics also have a non-commercial CC. The software is released under GPL, and consists for now of Arduino code and Xamarin code for our Android/IOS apps. The boards can be controlled by a modified Nunchuk controller or our smartphone app that uses the tilt sensor as input for braking and acceleration. But we are sure our growing community of customers are going to innovate some cool new controllers and maybe even an autopilot in the future.

The Hyperboard R2 by Faraday Motion.

How did you get the idea to produce this skateboard? Where do you get your inspiration from?

I had bought a 3D printer and started experimenting with Tinkercad, 3D Printing and materials. The outcome was a simple electric skateboard prototype that was inspired by the commercial electric skateboard company Boosted Boards and a range of DIY projects I found on the internet.

When and why did you start using 3D printed parts?

I bought my first 3D printer back in 2012/2013 but my first printer did not really print well and often broke down during prints. But after upgrading to an Ultimaker 2 everything changed and all of a sudden I could start to produce parts that could be used for my experiments. I kept thinking that 3D printing over time would replace many of the traditional manufacturing methods.

When printing motor brackets I experienced that motors could heat up and cause the plastics to bend, which then had to be replaced with new parts. I realized this was not optimal and started reaching out for small workshops in Copenhagen, but they were not interested in producing the small quantities I requested. So I decided to try i.materialise and look for alternative materials that could be used as motor brackets. To my surprise the prices were really cheap for alumide which seemed to fit my needs perfectly and I just decided to place my first order. We continue to have our motor brackets printed at i.materialise today as we produce small volume orders that are almost custom builds for our customers. For the Hyperboard R2 we have additionally experimented with 3D Printing our own disc brake caliper designs (yes, it has optional electric disc brakes) and it works very well in steel and alumide.

The Spine by Faraday Motion.

What value does 3D printing add to your product?

The speed and cost at which we can innovate, iterate and improve our products is just incredible. But we also see that 3D printing will make products much more personal and more suitable for the individual customer’s needs. One thing is of course to have a design modified to one’s liking, but when speaking about compact vehicles this can be extended to custom design, color, texture, materials, form and functionality that matches your exact individual need and preference.

What’s your ambition with this project? Where do you see it in the future?

We dream that we will be able to kick-start a new wave of electric vehicles made by innovators using our technology. Our vision is to enable everyone to get the electric vehicle of their dreams for transportation and fun. We are planning to do a kickstarter/crowdfunding campaign later this year.

Learn more about Sune and his team on the Faraday Motion website. Make sure to turn your idea into 3D printed reality by uploading your design here and ordering your HQ 3D print in more than 100 materials and finishes now.

Recommended Articles

No related posts.