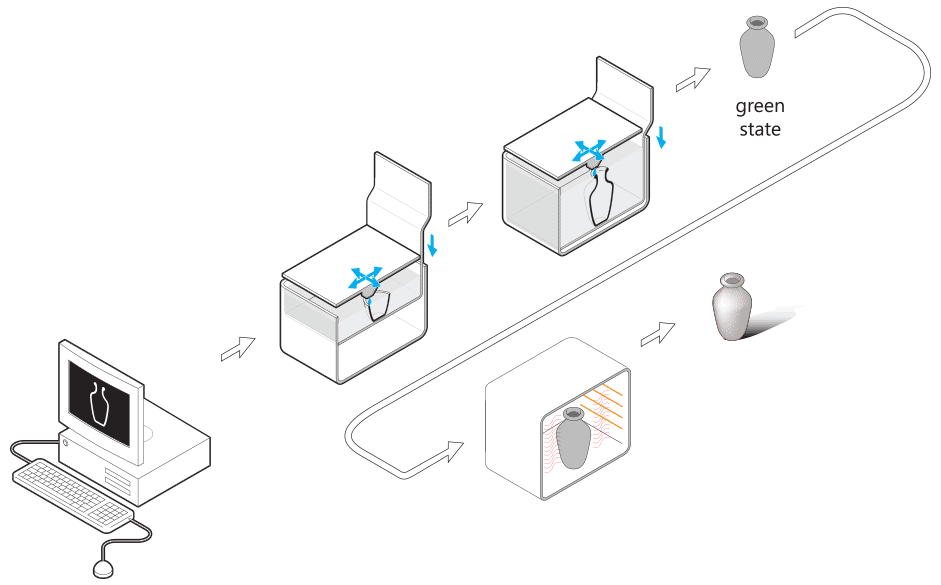

How It Works

Side view of the whole process

Side view of the whole process

Steel

With indirect metal printing in Steel, your part is created by binding together layers of stainless powder. Specifically, after a layer of steel powder is spread across the base of a “build box”, a special print head moves back and forth over the layer, and deposits binding agent at specific points, as directed by a computer and your design file. Once the layer is finished and it has been dried via powerful overhead heaters, a new layer of powder is spread, and the process begins again. In this way, layer by layer, from the bottom up, your part is created.

Once the printing is done, the build box is placed in a curing oven and your part is sintered. The extra powder that was not bound, and is not part of your design, is then removed. At this point, your part is still very fragile. This so-called “green state” will be the base of some of the design rules and limitations that follow below. Finally, via the use of a flute system, your design is infused with bronze, which replaces the binding agent. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

Materials

Steel

- Steel powder infused with bronze

- The cheapest form of metal printing

- Very strong and suitable for large objects

- Used for functional parts, spare parts, jewelry