Design Specifications

Pricing Info

The pricing for Aluminum is based on:

- Model volume: The volume of your model is used to calculate the material cost (mm³)

- The box around your model: An imaginary box around your model determines how much space your design will take up in the printer (X * Y * Z = mm³)

- Model surface

For Aluminum, we charge a minimum price per ordered piece. Unlike the startup cost (which is applied to most materials), this cost vanishes when the price is higher than the minimum price.

Typical Use

Aluminum is suitable for strong, light and precise metal parts. Applications range from spare parts to components of RC cars and gadgets.

Technology

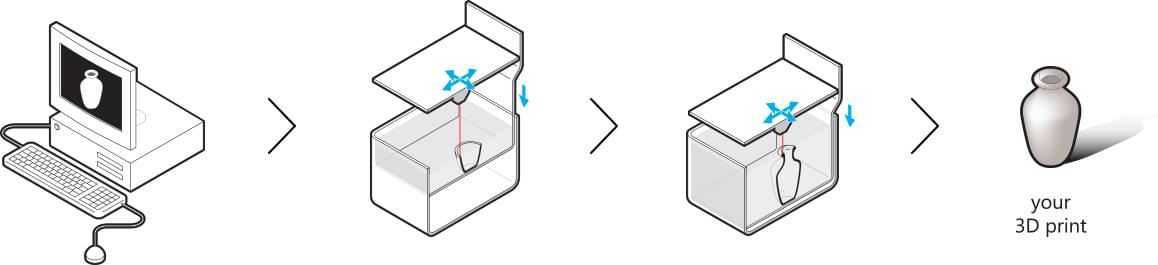

Metal 3D Printing – also known as Direct Metal Laser Sintering (DMLS) and Select Laser Melting (SLM) – is a laser-based technology that uses powdered metals. Similar to Laser Sintering, a high-powered laser selectively binds together particles on the powder bed while the machine distributes even layers of metallic powder. Support structures are automatically generated and built simultaneously in the same material and are later manually removed. Once complete, the part undergoes heat treatment.

Additional Information

- It's possible to make non-rectangular, organically shaped objects that are not able to be produced by any other process

- Because supports need to be removed manually, some evidence of removed support structures might remain on your model

- Any “overhanging” structures (e.g. the underside of a table) or angles smaller than 35° will tend to be less attractive with this process

- The ideal shape to make with this process is that of a mesh. It’s easy to design and delivers the best results

Learning about our materials is one thing, seeing and touching them another. That's why we've designed sample kits based on our Periodic Table of Materials.

Aluminum Natural Gray

Includes a natural gray Aluminum sample.