It’s Here: Take A Look At Our First Wooden 3D Prints

After receiving so many submissions for our ‘3D Printed Wood Challenge’, we are proud to announce the next step of our beta test: from now on, you can place your order for 3D printed wood. We are also happy to share images and video footage of our newest material.

Take a look at our newest wood prints: we printed some more models in order to give you a better impression of how our 3D printed wood looks and feels. Check out the video and images below to see our first wooden 3D prints.

The Material:

- Models printed in our wood material are constructed from a brown, very fine powder made from wood chips.

- Your model will have a brown, granular, rough look.

- The surface has a sandy, granular look, and is slightly porous. You can see this effect in the following images:

- If forced, objects printed in wood can break. That’s why we advise you to use this material for models that you put on your desk or on a shelf such as architectural scale models, figurines and awards.

- Wood is perfect for complex models, as it allows for interlocking and moving parts.

The Technology:

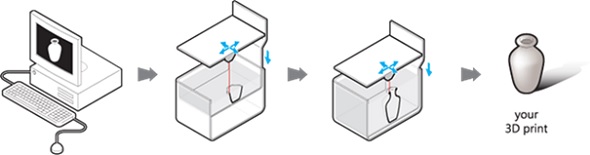

We do not use wood filament, but laser sintering for creating your wooden object. This technique gives you lots of design freedom. Your models are printed layer-by-layer using a laser that draws thin lines on a powder bed, which melts and bonds the powder with the previous, already solidified layers of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller.

The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy to melt the powder, forming a solid model. After a print job is finished, the result is a big block of warm powder with the printed models resting inside.

What’s to come?

- We will announce the winner of our “Wood Challenge” in the upcoming week. Stay tuned to see prints of the ‘Top 5’ submissions we received.

- We still consider 3D printed wood to be in a beta phase. Before officially launching a new material, we need to fine-tune production processes, get customer feedback and make sure that your expectations are met.

- If we see that feedback for 3D printed wood is positive, we might start working on further finishes.

Follow this link to learn more about the material and design guidelines for your first 3D print in wood. Click here to upload your 3D model and let us take care of printing your objects. Want to learn more about other materials? How about learning more about 3D printing in Multicolor, Gold, or Ceramics?

Update: Take a look at our 5 winning 3D prints here!

Recommended Articles

No related posts.