Fabricate Yourself: Using the Microsoft Kinnect to 3D print yourself

One of the most exciting research initiatives in 3D printing is Interactive Fabrication. Rather than focus on 3D printing itself Interactive Fabrication focusess on the interface. The team consisting of Karl D.D. Willis, Cheng Xu & Kuan-Ju Wu and headed by Mark Gross develops software and tools that let people design, in the broadest sense of the word. Beautiful Modeler is a great previous example of this. And now Karl Willis has developed Fabricate Yourself.

With Fabricate Yourself people can strike poses in front of a Microsoft Kinect. They can then choose their favorite pose and it will be turned into an STL file and 3D printed. By using a widely available easy to use platform such as the Kinect and by limiting people’s input to actions anyone can do quickly their interface lets anyone 3D print. Basically the team has made 3D printing yourself as easy as posing for a photo. It is tools such as Fabricate Yourself that will bring 3D printing to the widest audience. The Fabricate Yourself tool is not yet available for home use, and the resolution needs to be better but once it becomes available this tool might be the one to break this entire “create in 3D” thing wide open. If the Kinect Fabricate Yourself system could also be adapted to be used as a simple 3D scanner for the millions of Kinect users then it could bring creation to your livingroom. 8 million Microsoft Kinect units are already in people’s living room. This makes the Kinect a valuable platform for human computer interaction.

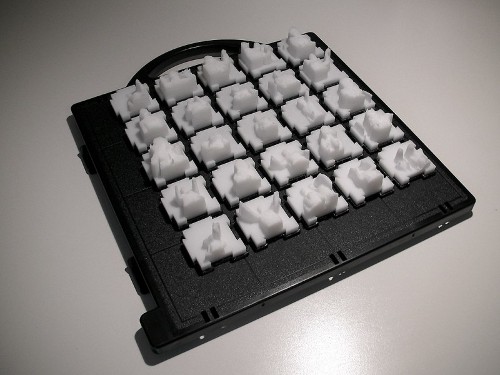

A removable build tray for the Stratasys Dimension Uprint with the Fabricate Yourself pieces on it.

3D printing as a technology has been arround for decades. You could already make any shape you wanted in the 90’s. But, how to design such a shape? 3D modeling and CAD are difficult and time consuming to learn. Waving your arms in front of a Kinect however makes it simple to get yourself 3D printed.

Here is a video of Fabricate Yourself in action.

The Fabricate Yourself tool was presented at the Tangible, Embedded and Embodied Interaction Conference an event which I will never forgive myself for not going to. The 3D printed pieces were made on a Stratasys Dimension Uprint 3D printer, Stratasys’ entry level system for the in office and home market (if you have $12,000). All the pieces were 3D printed as puzzle pieces so a puzzle could be made of the participants in the event. Incredibly cool, incredibly significant.

Did you like that? Did it kind of make you feel like this 3D printing thing was about to happen in a big way? What if I told you it already was happening in a big way? Approximately 10,000,000 people are walking around today with 3D printed hearing aids.

Follow us on Twitter or Facebook if you want to be kept in the loop of what’s happening in 3D printing.

Recommended Articles

No related posts.