The World’s Largest Rubik’s Cube Comes to i.materialise: Meet Its Designer

If you believe that a Rubik’s Cube is only a puzzle with 3x3x3 fields, then you haven’t heard of Oskar van Deventer yet. Thanks to his design skills and the use of 3D Printing, these twisty puzzles exist in any imaginable shape or size now. Read on to meet the designer of the world’s largest and toughest Rubik’s Cube.

The world’s largest and hardest 3D printed Rubiks’ Cube. Designed by Oskar van Deventer.

Hello Oskar, tell us a bit about yourself.

I am Oskar van Deventer, I’m 49 years old and I have been designing puzzles since I was 12. It has been a great hobby that brought me in contact with many interesting people and technologies. In my everyday lifeI work for a large research institute, where I develop new technologies and standards for the media industry. Are you going to buy a SmartTV next year? That TV will have a solution to synchronise the images and sound from your TV with the content on your tablet. I was one of the initiators and designers of that technology.

When did you get the idea of designing your own Rubik’s Cubes?

I have been designing mechanical puzzles since 1978, inspired by the book “Creative Puzzles of the World”, still a bestseller after more than 35 years. The trigger for designing twisty puzzles, as they are called, was when Bram Cohen pitched an idea for a novel twisty puzzle at the occasion of the International Puzzle Party in Australia in 2007.

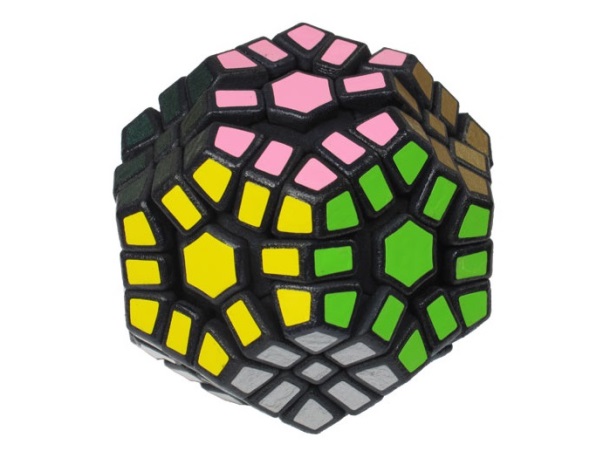

Now let’s take a closer look at your latest designs. What is special about the Fudgidron and the Krystian’s Cubes?

Fudgidron is a very fudged puzzle. It has a deformed geometry with squares and hexagons. I needed some innovation to make sure that the faces could rotate, while no pieces fall out despite the large gaps. That innovation was the use of centreboards under the edge pieces, which keeps those confined. Unfortunately, the puzzle does not turn too well.

Fudgidron by Oskar van Deventer

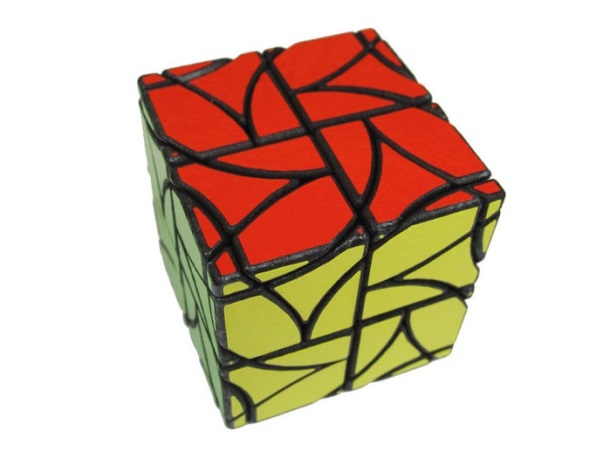

Krystian’s Cube is a new type of twisty puzzle, where a new type of turn is enabled when a face of the 2x2x2 cube is turned by 45 degrees. This puzzle does not fit easily in any of the existing categories of twisty puzzles. The first prototype of this puzzle works very well, and several people have already bought samples.

Krystian’s Cube by Oskar van Deventer

And of course you are famous for your world record. Could you tell us more about the “Over the Top Cube” – the world’s biggest cube?

The history of my Guinness World Record 17x17x17 cube has got a lot of attention. Inspired by the work of Panagiotis Verdes, who patented a design for higher-order magic cubes, I decided to go over the top. I found a technical solution to have the 17x17x17 cube stay together and turn stably despite its large number of pieces. That solution was the use of floating anchors. Each piece has a root that goes deep into the puzzle, keeping the pieces upright and locked together.

And that’s what this puzzle looks like:

Want to own the biggest twisty puzzle in the world? You can order it in Oskar’s shop on i.materialise now. And here is how to solve it:

Where do you get your inspiration and ideas for new designs from?

Technologies, materials, friends, brainstorming, forums and just spending a lot of time designing puzzles.

It must be tough to design such puzzles. Could you describe your workflow a little to us?

It starts with the idea, of course. The creative part is the design of the basic mechanism. For twisty puzzles that is the design of the cut curves, which is much more complex than you would expect. There are a lot of design patterns developed and used by our little designer community, discussed at the Twisty Puzzles Forum. After the creative part, it is just work. Rounding edges, rendering meshes, mesh clean-up, part stacking, uploading for 3D printing, ordering, receiving the 3D printed parts, opening the print shell, dyeing, sorting, assembly, nail-polish primer, stickering, breaking in and analysing my mistake(s) for a next round of prototyping. Or offering the puzzle for sale, if the prototype is a success, which is about 50% of the cases.

How long does it take you to design a new cube?

Anywhere between a few hours and 25 years. Typically, a full weekend suffices to complete a design.

Which material do you use and why?

My current material of choice is 3D printed nylon via SLS technology. i.materialise calls it Polyamide. That material is affordable, strong and flexible, and easy to dye. Some of my puzzles are in 3D printed Stainless Steel. I also use laser-cut wood, laser-cut acrylic and several other more basic technologies. And yes, I also know how to handle a jigsaw, which I have done for most of my long puzzle-making career.

Most of Oskar’s creations – like this Krystian’s Cube – are printed in Polyamide.

In what way does 3D printing help you in creating these cubes?

3D printing saves me a tremendous amount of time. When I used to cut puzzles by hand, it would take a long time to make a prototype. With 3D printing, I only need to click “add to cart”, so it has increased my productivity tremendously. Also, 3D printing is more accurate than cutting by hand, and it can achieve complicated shapes. New technological possibilities create room for new inspiration.

Thanks for the interview, Oskar. Where can we find more of your work?

Thanks! You can find all my videos on my YouTube account, see some of my work in my shop on i.materialise, and stay up to date via my website or my Facebook group. You can also find some of my creations on Sloyd and PuzzleMaster.

Do you feel like creating your own twisty puzzle? You can simply upload your design here and let us print it in high quality on industrial 3D printers. If you want to set up your own shop, just like Oskar, and learn how to drive sales, then this blog post is for you.

Recommended Articles

No related posts.