The future of 3D printing and Robotics by our guest blogger Michael Overstreet

3d printing is becoming a very powerful tool for robot makers in the present and will become even more important tool in the future. Here are a few of my ideas that I have been dreaming about.

Iteration* with 3d printing is becoming a very powerful development tool in the field of robotics. People should not underestimate how powerful iteration is in the creation, prototyping and development of a robotics platform. It all comes down to the time savings you get from the printing step of a new part or an upgrade to an existing part. If you have your own printer or have quick access to one then your turn around time could be hours! Not days or weeks. This speed of evaluation and testing of a part becomes a very powerful tool in the creation, development and prototyping of a robot. It also was the potential to save you a lot of money too.

Everyday more and more hobbyist, researchers and makers of robots are getting access to 3d printing because of dropping prices and a lot more choices. A robot maker can send the 3D design to a service like i.materialise for the finished part to be made. This can help a robot maker save time and as they only send the tested and completed robot to be printed by a high quality commercial printer. So 3D printing of robot parts will help robotics in many ways. It will decrease the cost of building a robot and it will decrease the cost and time to develop a robot design.

The nature of what a kit is will also change. Kits in the future will be just the parts that you cannot print out like servos, control boards and electronic parts. This will save the manufacturer and buyer of the kit money.

3D printing will also make it easier to share and develop open platform robot designs. As anyone with a 3D printer can download a shared design and print it out.

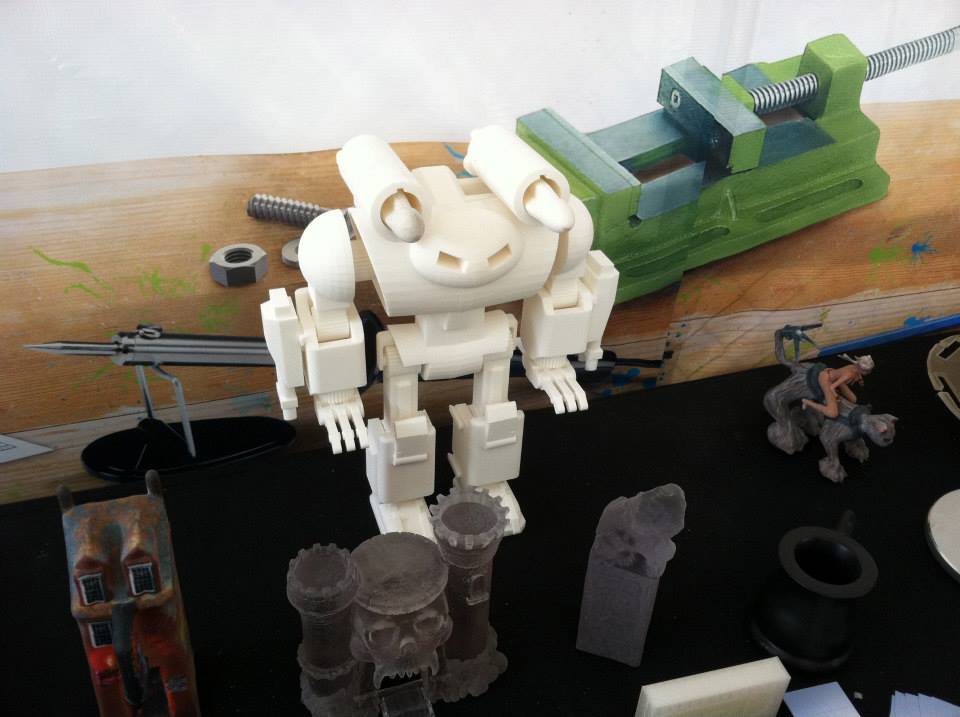

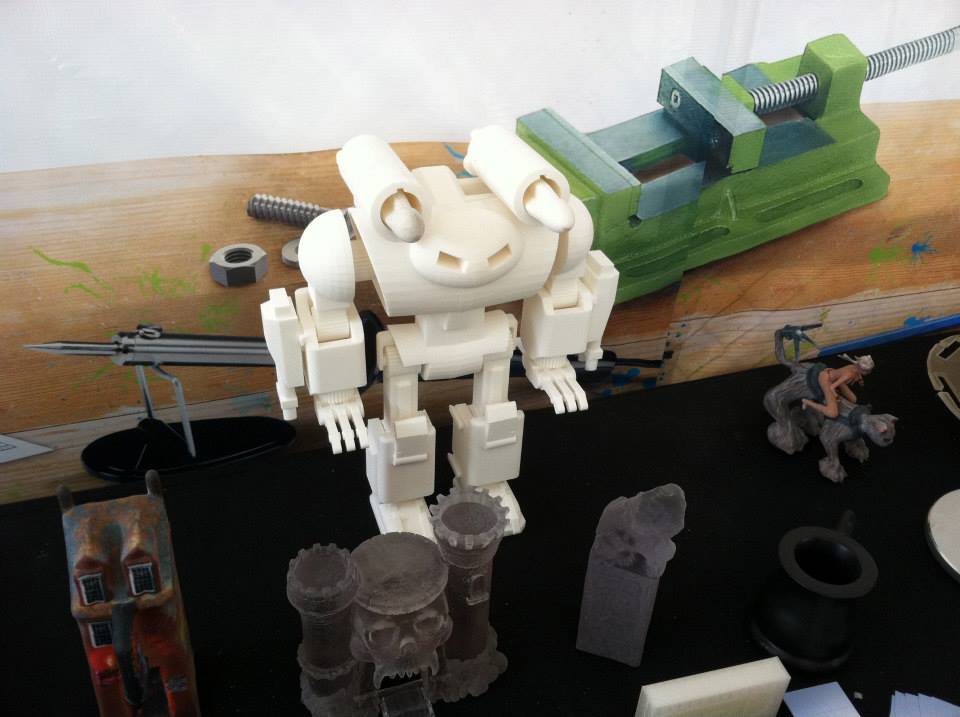

Garada K7, a project by Mike de Coninck, 3D printed at i.materialise.

3D printers have the possibility to change every aspect of how we buy and make things in the future. Being able to print with high quality materials like resins, stronger plastics or metals. High quality 3D printing will not be limited to a few people; everyone will have access to it.

As I look into the future I see unlimited possibilities as to how robotics and 3d printing can be used together. 3D printing in metals like titanium comes to mind or new plastics that are cheaper and stronger than metal. Robots making robots is another possibility. Which could be good or bad? The future that I must dream about is being like Tony Stark. Where I design a robot and then send it to my 3D printer or 3D printing service like i.materialise to build it, while I set back and watch.

*Iteration is a process in which a repetition of a sequence of operations yields results successively closer to a desired result.

Great Examples of 3d printed robot projects to follow:

- Dangerball by Michael Curry of Makerbot

- Jimmy the 21st century open sourced robot.

- My 3d printed Darwin-OP project and my under 1000.00 dollar humanoid robot project.

- InMoov humanoid

- Poppy the 3d printed humanoid robot

Michael Overstreet is a real maker and robotics enthousiast, you can follow his robotic adventures on his blog.

Recommended Articles

No related posts.