Meet the Designer: Josh Henry

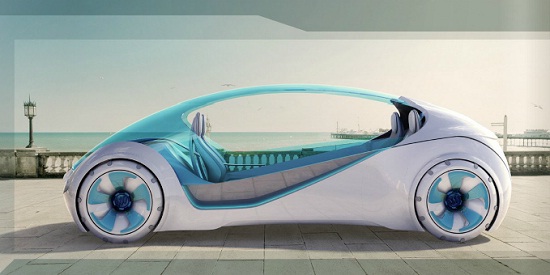

Not too long ago, we received an order at i.materialise to 3D print some pretty big transparent pieces. Our curiosity kicked in and we decided to contact the designer to find out what these transparent parts were for. To our surprise, Josh revealed to us that it was for his magnificent Ula Miami Concept Car that he was developing at the University of Cincinnati. As soon as knew that, we didn’t hesitate a second and contacted him for an interview.

Here’s what our friend Josh had to say…

Tell us a bit about yourself… Who is Josh Henry?

I am currently a Junior at The University of Cincinnati, in Cincinnati, Ohio, USA. Car design has been a passion of mine and is what I have wanted to do for as long as I can remember. Car design for me is really about creating a product with emotion. Creating a life, or a character if you will. Thinking about the interaction between a person and a vehicle and that emotional attachment that one has with the vehicle. These are things that fascinate me.

Where did you find the inspiration for your amphibious vehicle?

Well, A lot of the inspiration came from when I was down in Florida at my internship at Sea Ray Boats. There was a presentation given by Melissa Sikorski and Carrie Fodor, two very talented designers there at Sea Ray. The presentation was on Women and Boating. Making it short, it was about how to get more women involved in recreational boating. One of the things that came up was the intimidation of boating. It can be a scary thing for a new boater. Having to pull a trailer, launch a boat, and also the designs of boats themselves are fairly intimidating. So that’s where it all started. I just kept thinking about it when I got back to school, and the idea was, What if your “trailer” were the wheels to drive you on land? Combining your vehicle and your trailer as one unit, and the boat “pod” attaches to that. This vehicle is also to eliminate the decisions of need versus want. Many people would love to have a car and a boat, but many can not afford both. This eliminates that.

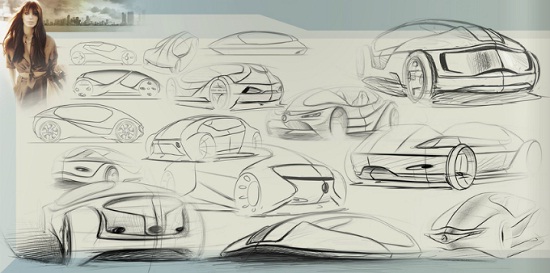

DESIGN. I wanted the design to be unique. I really thought about the surfaces and how they interact with one another. I wanted a lot of the details to be more subtle and make the vehicle much more approachable. One challenge from the beginning was how to make the two pieces (trailer and boat parts) cohesive and not only fit together , but look good both when they’re apart and together. I really liked the idea of utilizing those gaps between the pieces and how they fit together and really design them in a way that they’re a design detail and not try to just cover them up.

One thing I did was added LED lighting that really emphasizes the part lines and really adds a lot of dynamic energy to the overall look and feel of the vehicle. The overall theme I imagined and the picture I created in my head from the very beginning was a Woman living in a modern world in the glamorous Miami. This vehicle enables her to have the freedom she desires. Utilizing her vehicle on land and water as she pleases for both pleasure and transportation. Being in Miami I also imagined the use for night life or just driving down the road in South Beach in the sun. When I thought about adding the lighting on the vehicle, this is where I really just pictured this vehicle driving down South Beach at night by all the clubs with the dramatic aqua colored lighting pouring onto the strip. Very appropriate for Miami.

What made you choose 3D printing over other techniques for certain parts of the car?

I used 3D Printing over other techniques because the parts I was making were much to complex to be able to mill for instance.

What other production techniques were applied?

Everything on the vehicle was 3d printed, except for a few small acrylic pieces that were laser cut.

What software packages did you use to create your design?

Have you 3D printed anything else beside these transparent pieces?

Yes the entire concept car was 3D printed. The main body of the chassis was printed in eight pieces. The hull of the boat was printed in six pieces. The 4 seats were 4 pieces each.. in all there were about 84 or so pieces that had to be put together.. all 3D printed.

Where did you get your other parts 3D printed?

Everything I printed was here at school in our rapid prototype center. The main body pieces had to be broken up because of the dimensions of the printer we have. The material is the plaster powder material. The only parts I had sent out to other places were the parts to you and the two floating center consoles which were printed by another 3D printing service. The Parts were so thin If I would have printed them here with the powder, they would have just crumbled. So I needed a stronger material so they were printed with a strong flexible material.

What can we expect you to 3D print next?

Well my next big project will be my senior thesis. That has yet to start, so right now I am not to sure. But I would like to get into 3d abstract sculptures to print.

Where can we find more about you and your amazing work?

I am currently working on a website. I don’t know when that will be finished, but right now my portfolio is the best way to see my work.

Did you receive any additional help for this project?

Yes. The final renderings for this project (the nice ones with the ocean backgrounds) were done by the very talented CG Artist Michael Rule-Z Kotoff. You can find his work here.

Without a doubt in our minds, Josh Henry is a young man to keep an eye on and if this was only his work as Junior we can’t wait to his Master Thesis! Needless to say, we are very impressed with his final results want our friend Josh to know that we’re more than ready to help him bring his next exciting project to life whenever the time comes. You can now also see Josh’s designer profile and his work in our gallery.

Recommended Articles

No related posts.