Who is (y)our Business Process Manager?

My name is Wim Verstraeten. Consider me a battle scarred veteran in the field of the online ordering of 3d printed models. I date back from the era where Materialise was the only firm to have an online 3D printing service with its NextDay service which was started in 1997. I’m talking about the time when only the happy few had a mobile phone and Amazon and eBay had existed for almost 4 years.

I started in 1999, when I walked into the Materialise office to offer my services. I was intrigued by Magics Communicator, a free online collaboration tool for 3d models. At that time online video meetings were not free and broadband usage was expensive. Magics Communicator helped people to discuss and visualize their project, allowing them to instantly see the operations of their communication partner on the 3D model.

It was that tool that I upgraded to interact with the renewed NextDay Service internet website. Later on I converted the NextDay service to what we now know as OnSit

i.materialise on Karrewiet

Karrewiet is a Belgian children”s television show and i.materialise and our mother company Materialise were featured on the January 28th edition of the show. The segment is very short but you can see an intrpid kid reporter interview Miranda and get her drawing turned into a 3D print. You also see some fleeting images of the i.materialise and .MGX offices (and a shot of the kid reporter sitting on the KOL/MAC Root chair.Â

The best thing though is that the intrepid kid reporter is none other than Hanne. Her father is Wim, i.materialise”s head of production. You can watch the video here in Dutch, the episode is the 28th of January and the 3D printing segment starts at 3:40.

Who is (y)our director?

Hello,

My name is Miranda Bastijns and because I am the oldest of the i.materialise team, already have some grey hair, and don’t know how to design in 3D, the others call me boss.

I am also a dedicated fan of 3D printed objects, which is no wonder after having spent the last 13 years of my career at Europe’s largest 3D printing company.

As general marketing manager for Materialise, I have lived through the evolution from technical and medical applications of additive manufacturing, to the 3D printing of consumer goods. I have seen 3D printed dashboards, surgical drill guides, and washing machine parts pass by and now I get to see the creations of individuals as well.

I have seen many wonderful objects emerging from our 3D printers and it has been a source of frustration not being able to make them myself. Now, with i.materialise there is a super team behind me, able to develop all kind of tools that can help me, and others like me, turn our creativity into tangibl

The generative Mars Lamp, our first ceiling lamp!

Students Pieter-Jan Debuyst and Laurens Dekeyser got a class assignment to use Java to build a generative lamp through parametric design.  The students handled the assignment with aplomb and won the i.materialise contest that we were doing together with their University, the  Catholic University of Leuven.

We”re so taken by the first year Civil Engineering & Architecture student”s design that we”re offering it for sale starting today. This marks the introduction of our first 3D printed ceiling lamp.Â

The Mars Lamp costs 299 Euro ( that is $400 incl. ceiling mounting structure and transformer, excl. VAT and shipping). The lamp measures 15x15x13.8 cm (5.9×5.9×5.4 inch) and is 3D printed in polyamide. Â Please send an email to contact@i.materialise.com if you wish to order this design.

We think its lovely, what do you think of the Mars Lamp?

Who is (y)our Website Manager?

I’m Franky, a 30 years old and I’m the website manager of i.materialise. I wireframe, do some graphical design, occasionally write requirements for our developers, find interesting topics to blog about, take photos of all the nice things you design, make videos…and more. I love to talk about 3D printing, it’s fascinating and everyone deserves to know it exists.

Before joining Materialise, I worked as an editor for a video post-production company in Brussels. After a few years of TV shows, commercials and music videos, I decided to make a career switch. Thus I traded video editing for the exciting world of 3D printing. I barely knew what it was, but it sounded like the coolest thing in the world. Actually, it still does.

I consider myself not an expert at something but someone who knows a little bit about everything. I have college degrees in online journalism, multimedia and audiovisual communication.

When I’m not at work, I’m probably in the gym doing strength and c

Carl visualizes his daughter”s heart problems

My daughter has a heart problem, the images of the heart and my research into her condition has been helped greatly by being able to visualise this file. It also helps her understand the problem. As a natural structure I also think the heart is quite beautiful.

— Carl Hitchens

Carl Hitchens is Materialise”s Software Manager for the UK and Ireland. His daughter Megan was 6 in 2008 when she was diagnosed with two congenital heart defects, a PDA Patent Ductus Arteriosus and a VSD ventricular septal defect. Initially Megan”s parents “explained with books and she knew the problems and what symptoms she should be aware of.” Carl though works with Materialise software that is used to scan and render parts of the human body. MRI scans of a patient for example are used as a basis for surgical planning using Materialise Mimics. He decided to show his daughter her heart problem by 3D printing a scan of the heart using i.materialise. Megan liked the model and it helped her und

i.materialised a Christmas Leaf

Last year Steve Swisher made a lovely Christmas Leaf for his wife. We wanted to share this design and also wish you a Merry Christmas!

My wife loves leaves so I thought it would be nice to surprise her with a Christmas ornament leaf I designed myself. To give it a personal touch I put some custom words on the bottom. Voila!

— Steve Swisher

The Christmas Leaf is 3D printed using Stereolithography. The material used is a translucent epoxy and this is then hand painted with a translucent coat of green paint.

Hella Jongerius” 300 unique ceramic vases

Celebrated Dutch designer Hella Jongerius has an obsession with imperfection. She developed 300 unique vases to acompany special editions of her new book, Hella Jongerius:Misfit. The video below runs you through the entire production process of the vases.

We often think of 3D printing as the de facto technology for developing unique objects. Hella”s vases however are caramic and made by the venerable Royal Tichelaar Makkum (the Netherlands oldest company, founded in 1572). I think it is interesting to watch designers experiment with unique, with designing something that will be result in many different items that somehow stay well within the designer”s intent. Mr. Tichelaar hits the nail on the head in the video, “its not designing, its creating. Its exploring, its experimenting. Sometimes its very nice and somethimes you think its a bit strange, but its always beautiful. It always has a value, which you would like to cherish.” This is the best explanation I”ve heard yet of

Portal inspired Bookends on Thingiverse

We were thinking of some fun things to do with our Design Your Own Bookend. Because some of us are obsessed by Portal & Reddit, we had seen this awesome Portal Bookend on Reddit. So we asked Nicolas de Jaegre to make a Portal (and Reddit) inspired bookend fit for 3D printing. We put the 3D printing files on Thingiverse so you can download them and play with the files should you want to. Now everyone with a 3D printer can 3D print their own Portal inspired book ends. Enjoy!

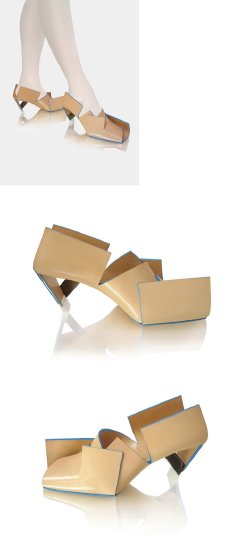

i.materialise interviews groundbreaking shoe designer Marloes ten Bhömer

In my mind there are only two shoe designers that are really revolutionizing shoe design. One is Rem D Koolhaas of United Nude and the other Marloes ten Bhömer. Both a are using cutting edge materials and design to make shoes contemporary and amazing again.

Marloes ten Bhömer is a lauded designer who has been called “one of the most promising designers of her generation”. She uses innovative production techniques, new materials and completely different ways of looking at form & function to redefine footwear. Marloes’ Rapidprototypeshoe, pictured below, is a great example of using 3D printing to create wearable footwear. We interviewed Marloes to find out more about her beautiful shoes.

Joris Peels: Why use 3D printing?

Marloes ten Bhömer: 3D printing is interesting to me on various levels.

It’s quite difficult to convince manufacturers to produce parts for products that are outside their usual industry. In my case I use production methods and materials that are rarely o