Recycling 3D Printing Materials: 4 Possible Solutions

When will more eco-friendly and sustainable materials be available for use in 3D printers? Something like hemp plastic or other biodegradable materials? What are the technical limitations and who is working on them? Read on to find answers to these and more questions about ABS recycling, PLA recycling, and new materials that are on their way. Below we outline, very broadly, four mayor developments in recycling and 3D printing. These developments are: recycling existing 3D printing materials, using materials that are already recycled as 3D printing materials, using bioplastics, and recycling on location.

ABS – Recycling existing 3D printing materials

ABS is one of the world’s most widely used 3D printing materials. It is used in the RepRaps, Makerbots and of course by the inventors of the Fused Deposition Modeling process Stratasys. While ABS is made from oil and lots of complicated sounding chemicals, it is recyclable. Fred Fischer, the Materials Business Development Director at Stratasys said that, “Stratasys has a company that comes in and picks up all our scrap and old sample parts and build sheets. These companies typically regrind all the materials. The regrind is often used to make products like carpet, plastic decking, lawn furniture, etc. Companies that will pick up and recycle the material exist pretty much anywhere in the developed world. A quick Google will often lead someone to find one in their local area.” That is indeed great news and it seems like it could scale along with the growth of 3D printing.

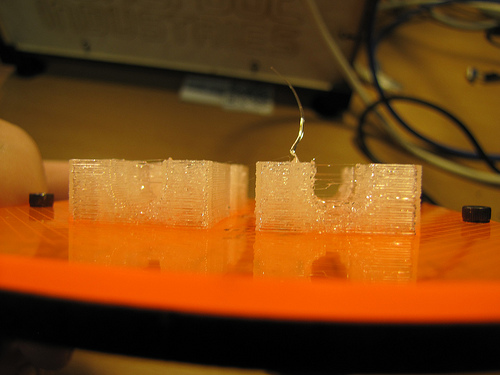

Photograph by Open3DP

Glass – Using materials that are already recycled as 3D printing materials

The Vitraglyphic & Prometal glass 3D printing processes are also very promising. By using glass, a material that is widely collected already, you could fit into existing recycling streams or potentially even recycle in the home. Mark Ganter, the inventor of the Vitraglyphic process told me that, “glass gets collected but glass has very few uses due to the energy cost to reuse it.” Perhaps 3D printing could absorb all that left over glass. Glass 3D printing machine development however is not that advanced and the models are rather fragile for many uses.

Photograph by Tony Buser

PLA – Bioplastics

One promising 3D printing material is PLA or polylactic acid. The material is made from starch and is part of a fast growing category of biopolymers or bioplastics. Since it is derived from natural sources it initially looks like the dream material. Makerbot has offered it and many users loved the popcorn smell it gave off during printing. However it is a rather difficult material to work with because even though it does not warp much it does tend to gunk up your 3D printer. Kristy Boyle of OpenMaterials.org also says that, “while PLA is a bio-material it is also very difficult to recycle.” PLA development is going ahead though and we will see improvements yet. One of the most promising is in Loopla a system for recycling used PLA into more PLA.

Recyclebot – recycling on location

Recyclebot is possible one of the best ideas ever. A small robot in your home that turns your household trash into 3D printing material. The recyclebot idea is being worked on by a lot of people and some use the term to describe robots that would sort all your recycling. But this recyclebot project turns milk bottles into 3D printing material. This would enable post consumer recycling in the home by the consumer. Self-recycling? Autorecycling? Feel free to invent your own buzzword in the comments. As a concept using existing plastic waste and recycling that in the home seems fantastic. We will have to wait a while to see if it works though. The project has not been updated in some months though but the Open3DP team is working on a similar system.

So I hope the above section gives you a good idea of some of the materials that are out there and who is working on them (there are many more!). In my mind there is little in the way of technical limitations. But, in many ways the recycling of 3D printing materials is in its infancy. While some researchers have been working on this for years, the total volume of 3D printed things has been very small. Recycling was therefore not on a lot of people’s agendas for a long time. Now that we are seeing a broader adoption of 3D printers in the home, increased use of 3D printing services & an increased use of 3D printing by industry recycling has become more pertinent. If you want to get involved some of the most inspiring stuff is being done by the Open3DP project.

If you want to learn more about ABS, visit its dedicated material page here – or take a look at the 18 most popular 3D printing materials including wood, steel, and ceramics. If you would like to print your design in any of those materials in professional quality, then simply upload your 3D file here and see your price instantly. If you want to learn more about the 3D printing technologies behind these 18 materials, we recommend you to take a look at this blog post.

Recommended Articles

No related posts.