Making 3D Printing More Flexible: New Color Option for Rubber-Like Material

Printing in flexible rubber-like material just got better: now in addition to our existing dyed black option, you can order your 3D print in natural white here at i.materialise! Read on to take a closer look at these color options and see what kind of objects can be created with this amazing material.

The color options: natural white and dyed black

3D printing flexible products such as bracelets, fashion accessories, scale model tires, or any other object you have in mind, has never been better: the natural white option for rubber-like material is finally here! Models printed in rubber-like are constructed from a very fine, granular white powder. The result is a strong, highly flexible, and durable material that can be dyed black afterwards. The material is abrasion-resistant and has a sandy, granular look.

The color options: natural white and dyed black

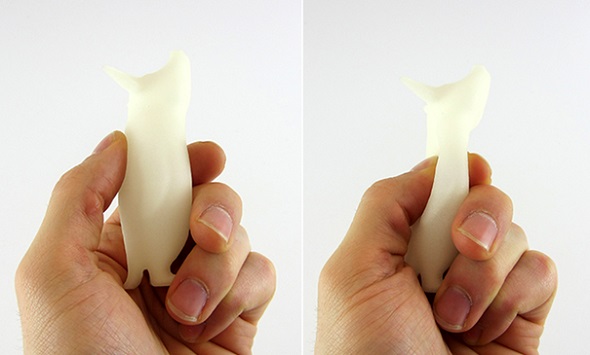

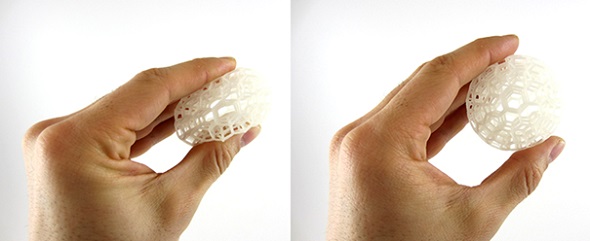

Rubber-like material is by far the most flexible material we offer here at i.materialise. The flexibility can be best described through the pictures of a 3D print below. As you can see, 3D prints in this material can be squeezed without breaking!

Testing the flexibility of our 3D printed ‘Piguine’

Testing the flexibility of a 3D printed ball

This flexibility makes rubber-like the perfect material for haute couture, models that need shock absorption, gadgets, or squeezable and functional models.

Printing flexible fashion items with rubber-like

And there’s even more great news: rubber-like gives designers a lot of freedom. Our printers let you print rubber-like objects up to a size of 32 x 27 x 30 cm as well as allowing you to print interlinking parts, which you can see in the image below. The prices will stay the same, but there’s still one downside: we cannot sell or distribute objects made from this material in the United States yet. We’re still working on this issue and hope to give you some more good news in the future!

Rubber-like gives designers a lot of freedom

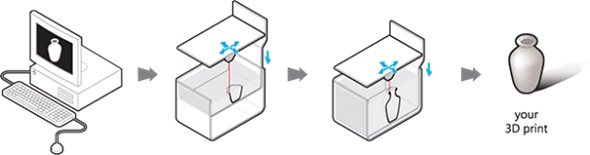

Selective Laser Sintering is used to build your design with this material. The models are printed layer by layer: a laser draws thin lines in the powder, which then melt and bond together in order to form a thin layer of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller. The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy needed to melt the powder and form a solid model. After a print job is finished, the result is a big block of heated powder with the printed model contained inside.

Selective Laser Sintering Process

Do you feel like making a 3D print in rubber-like material and trying out our new color option? Make sure you check out our material page for rubber-like and read the design guide for all the specifications on printing in this material. Not quite sure which material to use for your prints? Compare rubber-like with any other material here. Still in need of some rubber-like inspiration? Then we’ve got the blog post for you need right here.

Recommended Articles

No related posts.