How The Tripods come alive with 3D printing

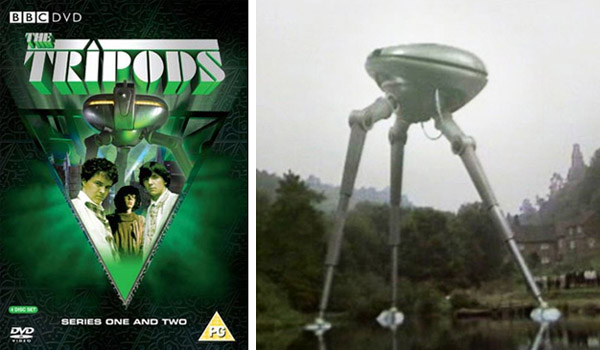

Do you know ‘The Tripods’? Well, Martin – one of our German customers – surely does. As a long time fan of the BBC science fiction series, broadcasted in the 1980s, he has just printed his childhood dream through i.materialise. That dream was owning a model of a Tripod.

Martin, where did you get the idea of creating a Tripod?

Martin: “When I was a child, I watched the BBC-series The Tripods on German television and ever since I’m a big fan of this great science-fiction story. I think the most fascinating thing for me were the Tripods themselves: huge and scary monsters made of metal. I always dreamt of owning a model of a Tripod and when I heard of i.materialise.com I thought the model could finally become real! So about 22 years after watching the first episode, I started to create one of these Tripods using 3D CAD Software.”

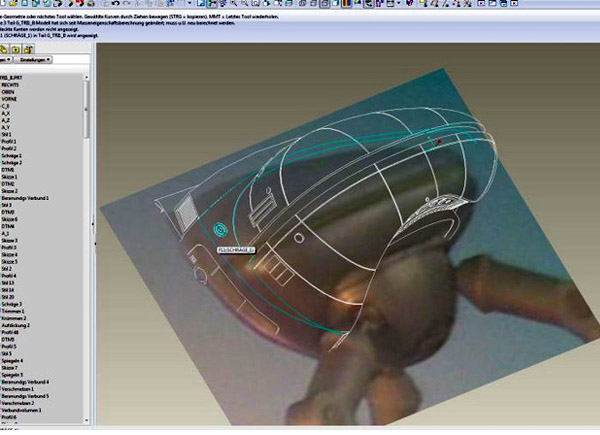

What software did you use to create the model?

Martin: “I designed the model with the student version of the program “Pro Engineer – Wildfire 4”. To make sure the construction would be correct, I imported some screenshots from the Tripods DVD.”

How did the printing of the parts go?

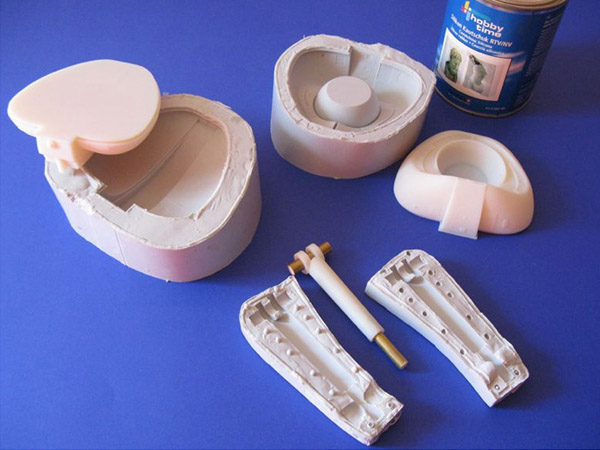

Martin: “The printing was actually the easiest step. I just had to upload the 3D files on the i.materialise website, you guys fixed the parts, printed them; and six days later the package arrived in Germany. While opening it, I could hear Christmas songs in my head. It’s hard to see because of the bright color, but all the parts are very detailed and every small bolt I created with the computer was printed successfully. I was very happy with the results. The next step for me was to create molds using silicon, because I wanted to cast the printed parts.”

Why did you cast the parts?

Martin: “There are two main reasons; first of all I didn’t want to damage the precious printed models. Casts I can make over and over again.

The other reason was that the Tripods have got three identical legs, so I only needed one printed leg and I could cast the others by myself. I filled some of the fluid resin in the moulds and waited about two minutes to get solid objects.”

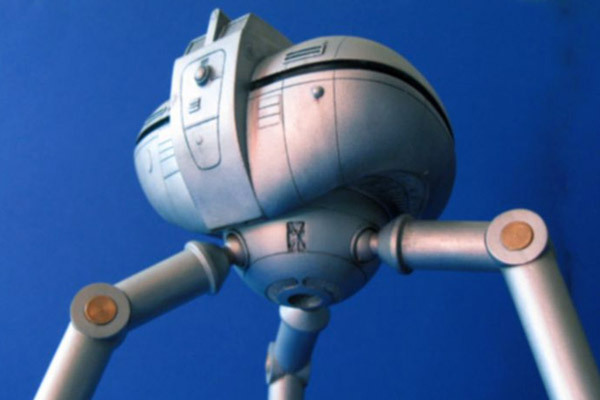

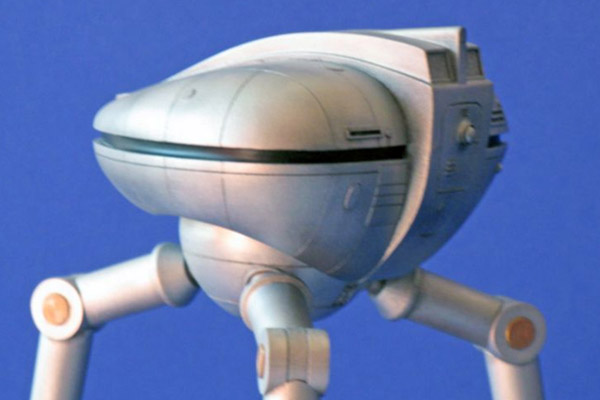

Have a look at the results of the casting procedure.With the grey resin you can see the details of the 3D print much better.

Martin: “I put some brass pipes into the molds to get more solid resin legs. They won’t bow under the weight of the massive head and I can easily adjust their length. Another reason was to have a good possibility to apply mounts for the parts.”

Martin: “After assambling all the parts, the whole Tripod stood in front of me for the first time, with a height of about 320 mm. That was a great moment for me. I just had to do some airbrush work to give the Tripod his flat aluminium finish like the original.”

Here are some pictures of the painted model:

Every hinge is fully movable, they are detained by some kind of rubber springs.

Martin: “Now one of the legendary Tripods guards my bookcase. Thank you, i.materialise.”

Recommended Articles

No related posts.