Columbia GSAPP Saturated Models 3D printed: Liquid Joint

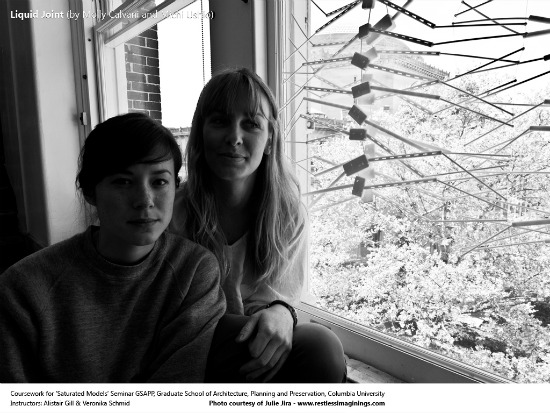

Alistair Gill and Veronika Schmid held a Saturated Models seminar at Columbia’s Graduate School of Architecture, Planning and Preservation. During the seminar the Master’s students explored 3D printing and created 3D printed objects. i.materialise made the resulting 3D prints. This is the fifth interview with a team of participating architecture students, Molly Calvani and Michi Ushio, and their project: Liquid Joint.

1. Who are you?

Molly Calvani + Michi Ushio, classmates at Columbia University. Master of Architecture 2011.

2. What is Liquid Joint?

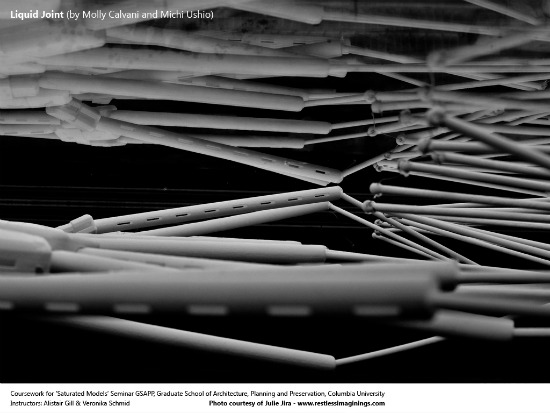

… Good question. Originally it was the goal to create a multi-directional, rolling joint that when assembled as a whole, could make up a system that seemed fluid, or liquid. Through different iterations and ultimately trying to realize a solid version of ”liquid” we arrived at something that perhaps begins to describe a model of an architectural discourse on the fluid and organic verses rigid and mechanic.

3. Why did you make it?

We had the opportunity to use i.materialise as part of a course at GSAPP and jumped at it. 3d printing is a technology that we don”t get to play around with very often– it seems like a technology that will let you do absolutely anything, but it also has very tangible constraints that we had to work with.

4. What software did you use to make it?

The 3d modeling was done in Rhinoceros.

5. What was the process by which you came to your design?

We began with the simple idea of a spine with the concept of creating a gradient, whether through light or material. We wanted to begin with an inherently natural or organic joint (human body) but also were interested in the idea of exploiting its machine-like qualities to express the actual process of which it was made (computer modeling, strings of emails, the advanced techniques of 3d printing). The course focused on the relationship of model and object as it pertains to the field of architecture, and then dealt with the new typologies of “modern” models. So our process was a series of questions and questioned the translation of concept to design to model and object.

6. Will you be using 3D printing more often in the future?

We hope so! Would you like to donate a printer to us?

7. Are you happy with the result?

Yes and No. There were some issues that we didn”t foresee, mostly because we didn”t do any physical models or iterations as part of the process of speculation and a purposeful detachment from models as final and finite products. The actual object is less of a model of what we designed, and more of a model of the result and process of designing… but, even so, it pleasantly surprised us in the end.

Recommended Articles

No related posts.