Cloning the RepRap Prusa in under 30 minutes

The grounbreaking research/hacking team at The University of Washington’s Solheim lab have begun cloning RepRaps. The RepRap project is a project that aims to make an open source self-replicating 3D printer. If sucessful this would make 3D printers available for the cost of the materials alone. At the Solheim Lab the Open3DP project is undertaking lots of research to support open 3D printing innitiatives. They have just now annouced that they can produce all the plastic parts for the Prusa Mendel in 30 minutes using molding. They call the resulting Prusa clones Clonedels. They represents a significant cost and time saving for producing the Prusa and should help put 3D printers into the hands of more people.

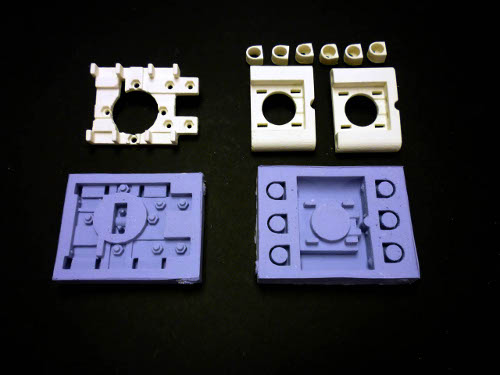

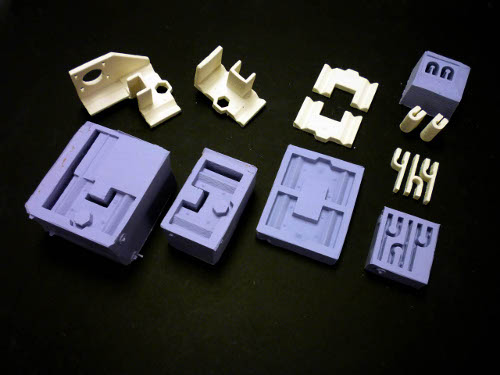

The Prusa Mendel is the simlpest 3D printer in RepRap’s line up. Open3DP’s RepRap breeding program set itself a goal of producing ten Mendels in ten weeks. The team redesigned the parts to they could be used for silicon RTV molding. They then 3D printed the parts and produced the molds from them. The molds have sucessfully been used to construct Prusas. Now the team has a new goal to release the STL files to the broader community so their innovation can spread.

This is, to me, dizzying stuff. An innovation such as theirs can now qucikly spread throught the Maker community. This kind of thing really illustrates how 3D printing and networked people can accelerate product development and innovation. By innovating at a constraint point, namely the cost of 3D printers this development can act as a catalyst for the entire 3D printing market. Bravo Open3DP

Follow us on Twitter here, we”re going places. Or you can like us on Facebook. Because we”re like, likeable. Or you might want to stay in touch because we eat, sleep & dream 3D printing.

Via Open3DP.

Recommended Articles

No related posts.