3D Printing Technologies: Laser Sintering

Contrary to popular belief, there’s not a one-size-fits-all approach to 3D printing. Although we offer 17 different materials and over 90 possible color and finish combinations, it takes us several different technologies to get the job done. In general, 3D printing technologies can be split up into two groups: direct and indirect 3D printing. The main difference lies in the fact that the design is made from 3D printing (direct) or 3D printing was used in the process of creating your model (indirect). In this article, we’ll dive into laser sintering, by far one of the most popular 3D printing technologies, and an example of a direct 3D printing technique.

How it works: 3D laser sintering

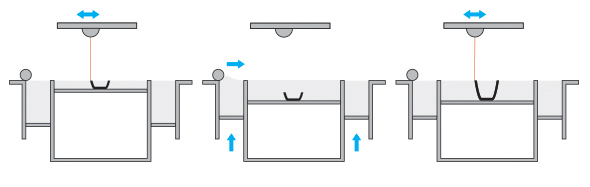

Starting from a 3D model, a model is built by cutting it into thin layers via specialized software. The model is then printed layer by layer by a laser that draws thin lines in the powder, which melts and bonds it together in order to form a thin layer of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller. The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy to melt the powder, forming a solid model. After a print job is finished, the result is a big block of heated powder with the printed models contained inside.

Laser sintering materials

- Suitable for complex models, concept models, small series of models (several copies of a model), lamps, and functional models.

- Strong, somewhat flexible material that can take small impacts and resist some pressure while being bent

- Sandy, granular looking surface, but the material can be polished and/or dyed or finished with a velvet coating

- Slightly porous

- Allows the greatest freedom of design of all 3D printing techniques

- A blend of gray aluminum powder and Polyamide

- Suitable for complex models, concept models, small series of models (several copies of a model), lamps, and functional models.

- Strong, somewhat rigid material that can take small impacts and resist some pressure while being bent

- Sandy, granular looking surface, but the material can be dyed

- Slightly porous

- Allows the greatest freedom of design of all 3D printing techniques

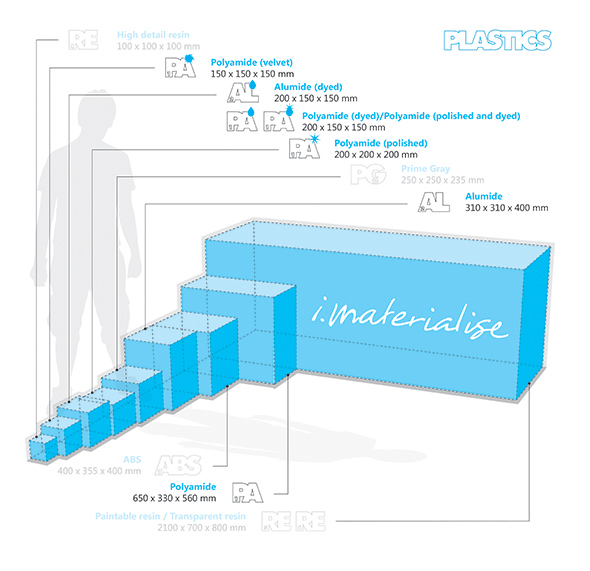

Laser sintering 3D printing sizes

Trivia about 3D printing with laser sintering

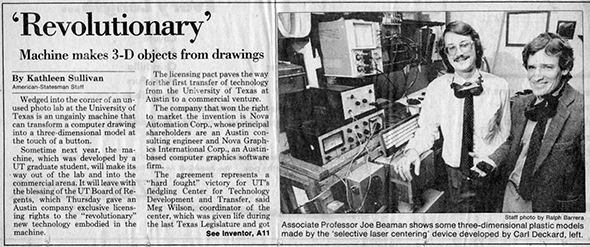

Photo of Carl Deckard and Joe Beaman from an Austin American Newspaper article dating from 1987 announcing the licensing of selective laser sintering technology to an Austin, Texas company named Nova Animation, which later changed its name to DTM.

Did you know that…

- Laser sintering was developed and patented in the 1980s at the University of Texas at Austin, under sponsorship of DARPA, by mechanical engineering Professor Joe Beaman with student Carl Deckard and with guidance in laser technology and materials by Professor Dave Bourell. You can read the whole background story here.

- Deckard and Beaman were involved in the founding of one of the first 3D printing startups, Desk Top Manufacturing (DTM) Corp., in 1989.

- Materialise has been using this technology since 1999

- The SinterStation 2000, the first commercial product, was originally designed by DTM Corporation in 1992 and marketed in 1993.

SinterStation 2000

Can’t get enough of this exciting technology and its materials? Then dive into our elaborate material pages for a lot more information or get your laser-sintered 3D print by uploading your model to our 3D printing online service here.

Recommended Articles

No related posts.