Introducing 3D Printed Copper: It Just Makes Cents!

Once again we’re proud to announce a new member in our growing family of 3D printing materials. After offering 3D printing in gold, silver, ceramics, and even wood, we can now let you create and order 3D prints in our 19th material as of today: copper!

Introducing 3D Printed Copper

Today, for the first time ever, you have the chance to get your design 3D printed in copper with i.materialise! Copper is an affordable metal with a very high thermal and electrical conductivity. Watch the video above to see it with your own eyes!

Copper is used a variety of objects: typically, wires, cables, and parts of electronic items are made of copper since this material is such a great conductor. It is also often used for tubes, door knobs, handles, and coins since it does not attract bacteria. Besides, copper is known to be found in architecture, household items, art, medals, and jewelry.

Colors and Finishes for Copper

Copper has a reddish color by nature. Your model is polished magnetically and by hand. You have the option of coating your copper model against scratches with a clear PU coat. This coat will also slow down corrosion but it won’t prevent oxidation in the long run as the material is very sensitive. Visually, there is no real difference between uncoated and PU-coated parts at first. When corrosion starts to happen, the difference will become apparent and a greenish verdigris or tarnish (patina) will become visible.

Designing for Copper

Have you already designed something for our gold, silver, bronze, or brass materials? Then there’s another bit of good news: the design specifications for copper are exactly the same. Minimum wall thickness (0.5 mm), minimum details (0.3 mm), and maximum printing size (88 x 63 x 125 mm) won’t change. Click here to find out more about the design specification for printing in copper.

The Technology behind a Copper 3D Print

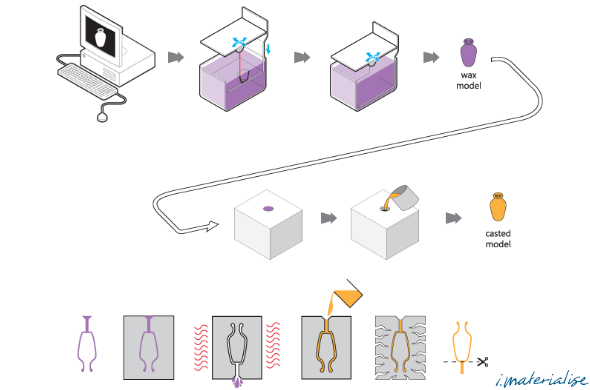

This is due to the fact that the technology for printing in gold, silver, bronze, brass, and copper is the same: a mix of lost wax casting and 3D printing. First, a wax cast of your item is 3D printed and then covered in fine plaster. When the plaster solidifies, it is placed in an oven and heated to a point where the wax is completely melted out. The metal is then poured into the empty cast and your real 3D printed metal item is created. In the final step the item is finished manually. Click here if you want to find out more about the technological aspects of printing with copper.

Lost wax casting & 3D printing is used for a variety of metals, including silver, gold, brass, bronze … and copper!

Do you feel like creating a 3D print in copper now? Make sure you check out our material page about copper first to learn more about it. Upload your model here to order your 3D printed copper item today, or visit this page to compare it with the 18 other 3D printing materials we offer.

Recommended Articles

No related posts.