3D Printing for Product Design

3D printing allows us to dream. Not just because the freedom of design it enables is limitless, but because it’s a good way to test out our ideas and designs in the real world. This is especially useful for product designers like Elia Furgiuele.

Elia Furgiuele is a Swiss Industrial Designer who uses i.materialise to 3D print prototypes for his designs, and he can tell us a thing or two about how to use 3D printing to improve the design of his products to perfection.

He graduated in 2009 from the Technical Industrial Designer (SSSAA) course at CSIA in Lugano. He has worked as a building and industrial designer and since 2016 he is flying solo as a freelance industrial designer.

Elia has been designing for 3D printing since high school and is well aware of the important role that 3D printing plays in the process of creating a good design.

From idea to 3D print

Elia explains a bit more about the 3D design process that he follows:

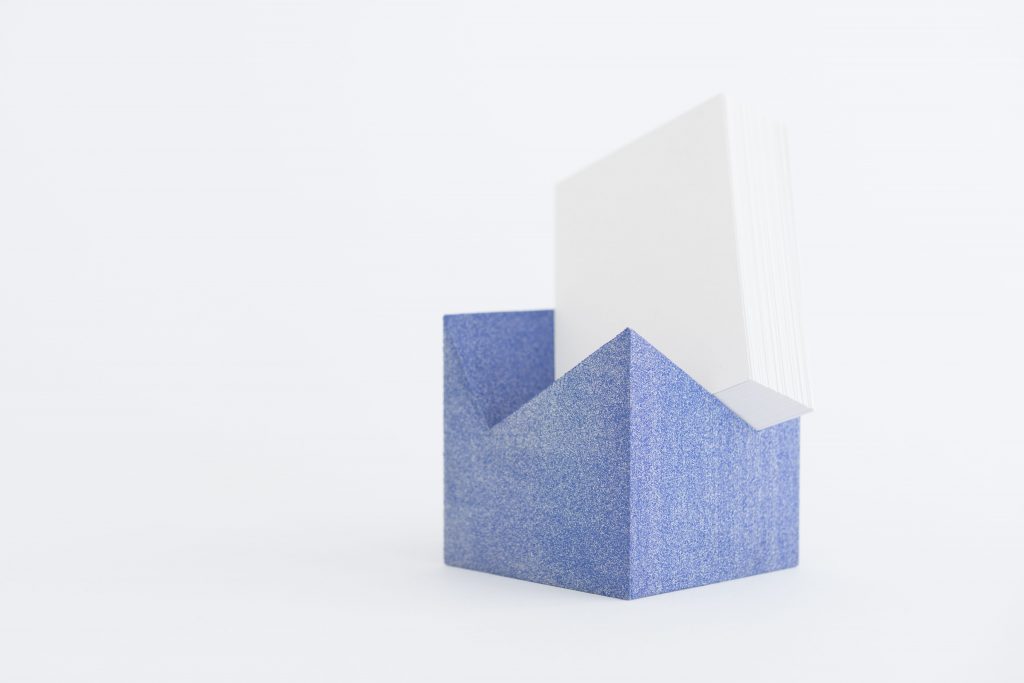

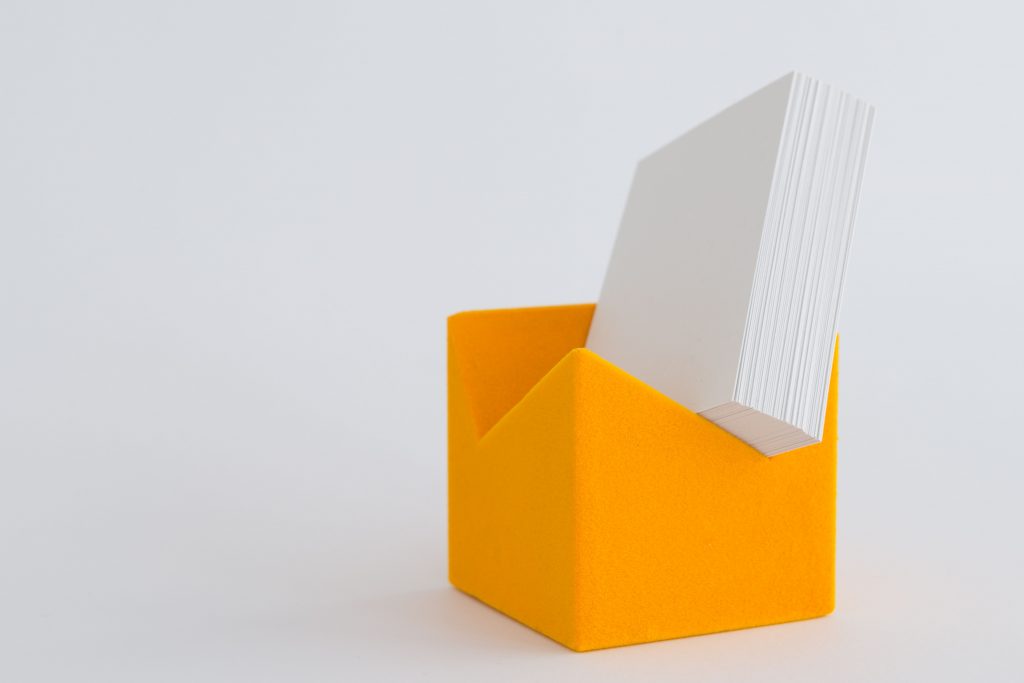

“Usually, I use 3D printing to test dimensions, ergonomics, space, proportion, and usability. Using different colors and materials could add value and give a strong identity to my products.”

His favorite 3D design software is Creo Parametric.“It’s fast, user-friendly and it allows me to check the design thoroughly in a simple and intuitive way“. He even taught students how to use this design software in a class in collaboration with Parametric Design Suisse.

I use 3D printing to test dimensions, ergonomics, space, proportions and usability. Using different colors and materials could add value and give a strong identity to my products.

Prototyping for the best design

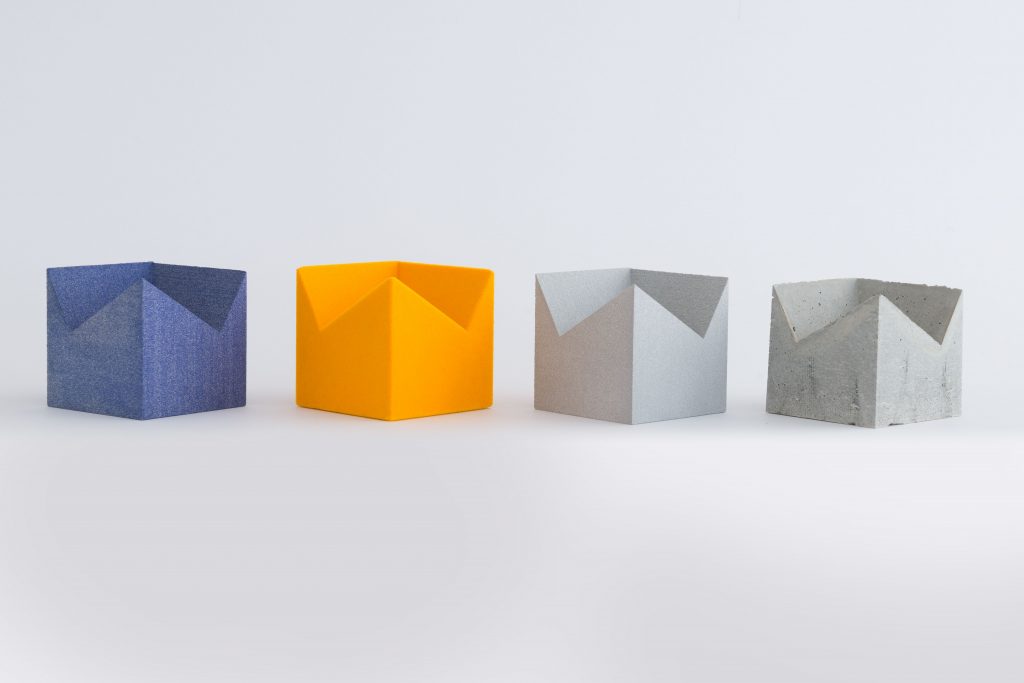

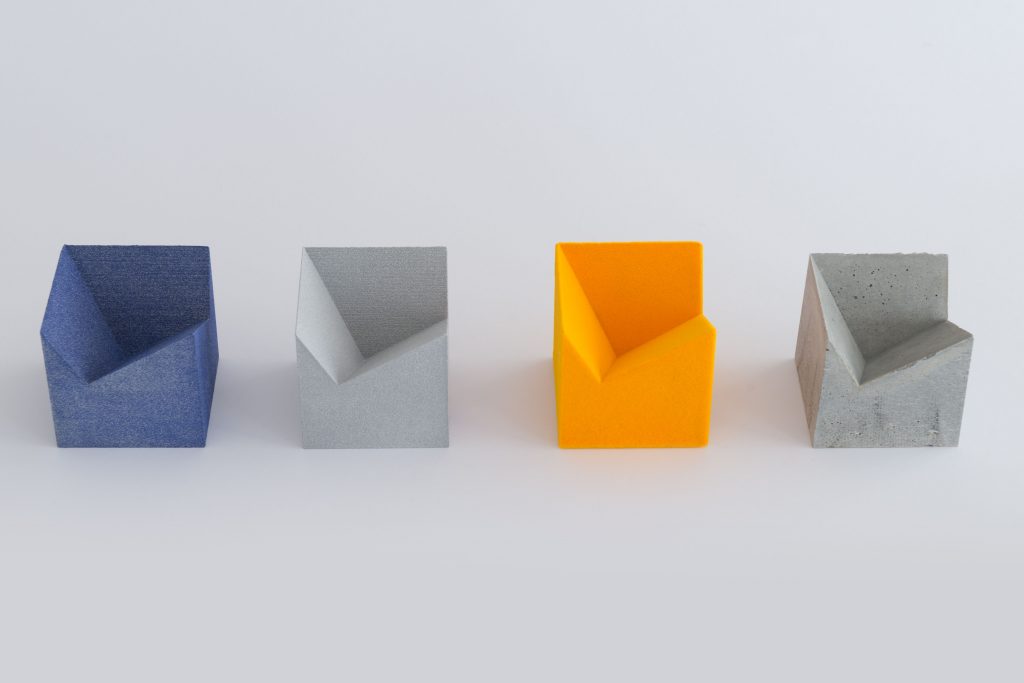

Elia 3D prints his prototypes in Polyamide (SLS) because he can choose from a wide variety of colors and because it’s more affordable than the other materials. “For the final product, I can choose the right material in terms of consistency, weight, reflection, color, and connotation”.

Design is also very important for the perfect 3D print: “Firstly, I would recommend being as clean as possible when creating your design in whatever software. Secondly, it’s important to consider the thickness of your design in order to remove unnecessary material and save money.”

Elia also suggests spending some time (and money) to print prototypes before printing a final product with a specific material, to be sure that your product works in real life.

For the final product I can choose the right material in terms of consistency, weight, reflection, color and connotation.

A 3D printing solution for each design

One of his recent projects is a cutlery set. “It was a big challenge because instead of thinking about one element, you have to think about a set of things that need coherence and consistency among them to make them feel part of the same family of ideas. After I had a clear idea, I used 3D printing to test the design!”

Another recent design is a cardholder. The original idea was to create a magazine holder but due to dimension limitations, Elia 3D printed the card stand instead to test the design. He also 3D printed a mold in standard resin to create the perfectly shaped finished concrete cardholder.

Design and materials, never-ending ideas

3D printing offers many options for designers in terms of materials, as well as the possibility to create prototypes and short series of products.

Elia has a project for an ashtray now and he wants to try alumide and copper for his product design projects.

“I also want to use rubber-like materials for some fashion design. Another idea I have is to use ABS for junctions to make a library, a table, and a chair”, says Elia.

Discover more stories on our blog about prototyping with 3D printing and product design.

If you want to follow Elia’s steps and design your models in PTC’s Creo software, you can print your designs directly through i.materialise thanks to the integration of both tools.

If you are using another 3D design software, you can easily upload your 3D files to our 3D printing platform and get an instant quote for your 3D prints.

Recommended Articles

No related posts.