Design Specifications

±0.9%(XY) up to ±1.8% (Z) with lower limits on ±1 mm (XY) up to ±1.5mm (Z)

- 274 x 370 x 380 mm (Natural)

- 150 x 150 x 150 mm (Black dye)

- 256 x 340 x 360 mm (Extra Smooth)

Pricing Info

The pricing for Rubber-like is based on the volume your models take up in the 3D printing machine. This includes the volume of your models and the surrounding space they require in the printer’s build chamber to ensure a successful print.

For Rubber-like, we charge a minimum price per ordered piece. Unlike the startup cost (which is applied to most materials), this cost vanishes when the price is higher than the minimum price. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

The pricing for the Extra Smooth finish is based on the volume your models.

Typical Use

Rubber-like can be used for fashion pieces, jewelry, shoe soles, prototypes or squeezable gadgets.

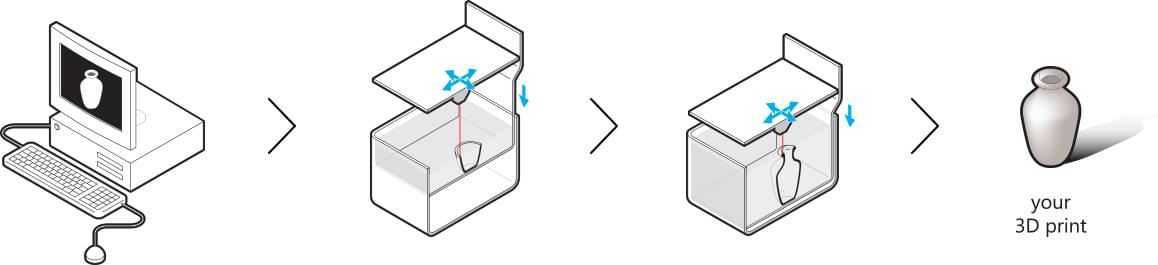

Technology

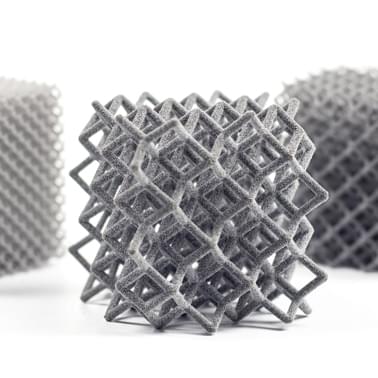

HP Multi Jet Fusion is a powder-based technology but doesn’t use lasers. The powder bed is heated uniformly at the outset. A fusing agent is jetted where particles need to be selectively molten, and a detailing agent is jetted around the contours to improve part resolution. While lamps pass over the surface of the powder bed, the jetted material captures the heat and helps distribute it evenly.

Additional Information

- The gray color is due to mixing the white TPU powder with the black drops of ink used as fusing and detailing agents

- Slight variations in color may occur throughout your model and between different models. If you want a uniform look, we recommend the black dyed or extra smooth finish.

- Rubber-like has a hardness of Shore A 90, which means it is a hard material on the Shore A hardness scale. Shore A 90 can be compared to a hardness situated between a rubber shoe heel and a rubber shopping cart wheel.

Learning about our materials is one thing, seeing and touching them another. That's why we've designed sample kits based on our Periodic Table of Materials.

Rubber-like (MJF) Sample Kit

Includes a natural gray, dyed black and extra Smooth Rubber-like sample.