Design Specifications

Pricing Info

The pricing for Polypropylene is based on the volume your models take up in the 3D printing machine. This includes the volume of your models and the surrounding space they require in the printer’s build chamber to ensure a successful print.

For Polypropylene, we charge a minimum price per ordered piece. Unlike the startup cost (which is applied to most materials), this cost vanishes when the price is higher than the minimum price. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Typical Use

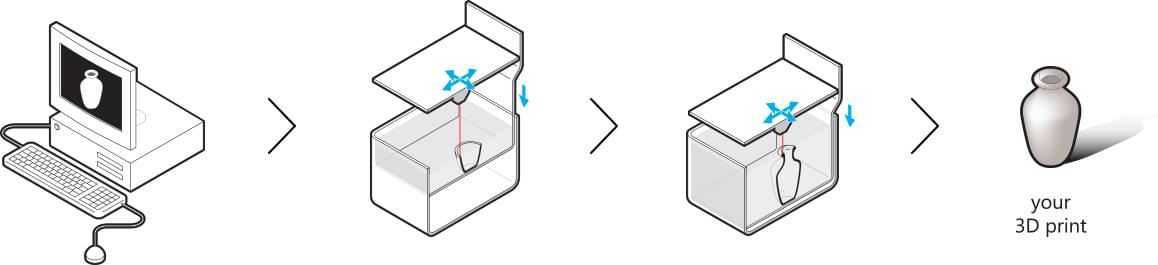

Technology

PP Natural

Includes a sample of Polypropylene.