Bronze is an alloy consisting primarily of copper. It’s a strong, affordable option for printing models in metal, with an antique look and a reddish tint.

Design Specifications

Pricing Info

The pricing for Bronze is based on model volume, which is the volume of your model used to calculate the material cost (mm³).

Additionally, a startup cost is applied to the price of your model. This is a fixed cost independent from the parameters of your model. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Typical Use

Bronze can be used for steampunk designs, miniatures, sculptures, antique-looking jewelry or pre-print tests (e.g. to form-fit before ordering gold or silver).

Technology

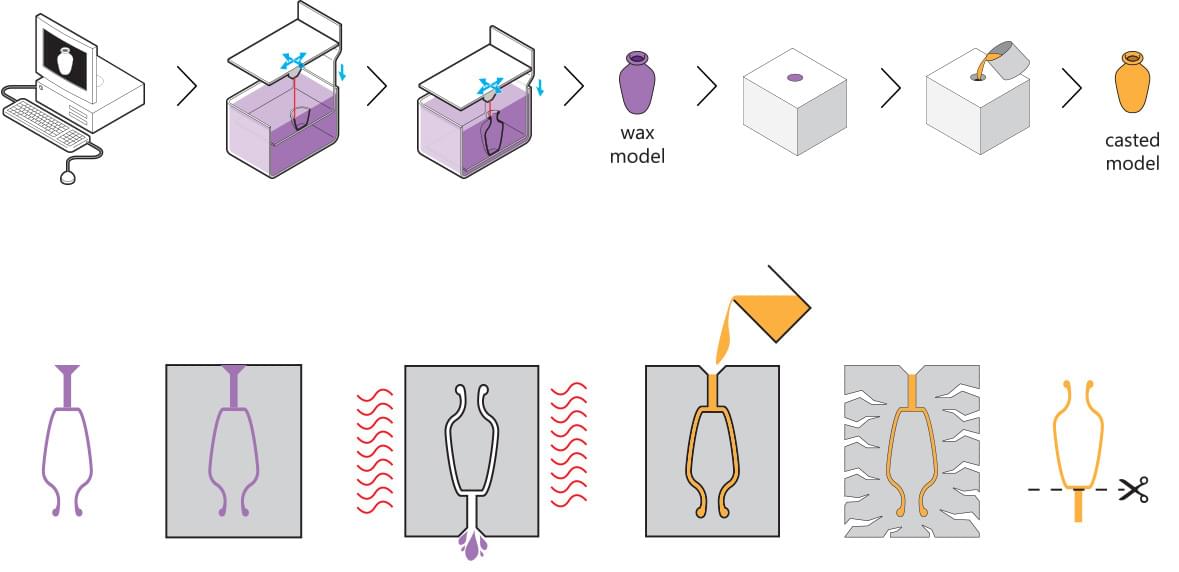

Wax 3D printing and lost-wax casting are used to build your design when using this material. The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure your model doesn’t fall apart. These support structures are automatically generated and manually removed after the printing process. After support structures are removed and your model is cleaned, the model can be prepared for casting.

First, one or more wax sprues will be attached to your model. Next, the sprue and model will be attached to a wax ‘tree’, together with a bunch of other models. The tree is then placed in a flask and covered in fine plaster. When the plaster solidifies, it forms a mold for bronze casting. The plaster mold is then put in an oven and heated for several hours to a point where the wax is completely burned out.

Then, molten bronze is poured in to fill the cavities left by the wax. Once the bronze has cooled and solidified, the plaster mold is broken and the bronze models are removed by hand. Finally, your model is filed and sanded to get rid of the sprues. Depending on the selected finish, it will be polished and/or PU-coated.

Additional Information

- With time and wear, bronze will naturally tarnish but a PU coating can be added to slow down the process

- Due to the nature of the process (lost-wax casting and printing) used in the production of bronze, interlocking or enclosed parts are not possible

- Bronze consists of 90% copper and 10% tin

Learning about our materials is one thing, seeing and touching them another. That's why we've designed sample kits based on our Periodic Table of Materials.

Bronze Natural Uncoated

Includes a natural uncoated Bronze sample.

Bronze Natural PU Coated

Includes a natural PU coated Bronze sample.

Bronze Polished PU Coated

Includes a polished PU coated Bronze sample.