Design Specifications

Pricing Info

The price of brass is directly affected by the volume of the model you intend to print. The bigger the volume, the less you pay per cm³.

Depending on the type of plating, electroplated brass models cost between 5 EUR to 9 EUR more per model than the natural PU coating. The yellow gold-plated finish is the cheapest plating option. The red gold-plating and the rhodium-plated finish are about 7 EUR more per model than the natural PU coating. The black color-plating and chrome-plated finish are the most expensive of all the brass plating options.

Typical Use

Brass can be typically used for detailed miniatures, sculptures, jewelry or pre-print tests (e.g. to form-fit before ordering Gold or Silver). The material is perfect if you want your piece to bling as Gold but you don’t want to spend so much money.

Technology

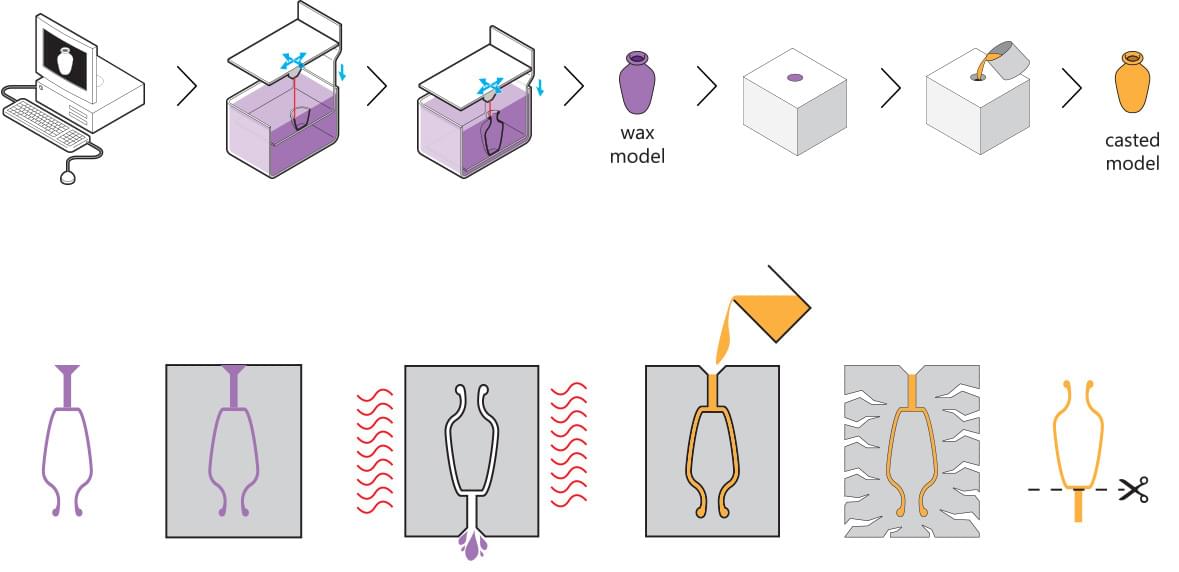

Wax 3D printing and lost wax casting are used to build your design when using this material. The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure your model doesn’t fall apart. These support structures are automatically generated and manually removed after the printing process. After support structures are removed and your model is cleaned, the model can be prepared for casting.

First, one or more wax sprues will be attached to your model. Next, the sprue and model will be attached to a wax ‘tree’, together with a bunch of other models. The tree is then placed in a flask and covered in fine plaster. When the plaster solidifies, it forms a mold for brass casting. The plaster mold is then put in an oven and heated for several hours to a point where the wax is completely burned out.

Then, molten brass is poured in to fill the cavities left by the wax. Once the brass has cooled and solidified, the plaster mold is broken and the brass models are removed by hand. Finally, your model is filed and sanded to get rid of the sprues. It will be polished, plated and/or PU-coated according to the finish you desire.

Additional Information

- A PU coating provides extra protection for the plating, enabling us to offer a 6-month guarantee for the plating

- Due to the nature of the process (lost-wax casting and printing) used in the production of brass, interlocking or enclosed parts are not possible

- Brass oxidizes (the surface gets a greenish hue) if it isn’t plated, PU-coated or varnished

- Chrome-plated polished brass contains traces of nickel

- Brass consists of 80% copper, 15% zinc, and 5% tin

Brass Natural PU Coated

Includes a natural PU coated Brass sample.

Brass Yellow Gold-Plated Polished

Includes a yellow gold-plated polished Brass sample.

Brass Red Gold-Plated Polished

Includes a red gold-plated polished Brass sample.

Brass Black Color-Plated Polished

Includes a black color-plated polished Brass sample.

Brass Chrome-Plated Polished

Includes a chrome-plated polished Brass sample.

Brass Rhodium-Plated Polished

Includes a rhodium-plated polished Brass sample.