How Does 3D Printing Work? These Videos Hold the Answer.

So how does 3D printing really work? Actually, there is no single, easy answer to this, since ‘3D printing’ includes many different technologies. While some printers work with filament, others use powder, and yet others work with liquid. To bring some structure into this, we put together a video overview about the most important 3D printing technologies.

How Does 3D Printing Work?

There are several 3D printing technologies and they all work very differently. What all the technologies have in common is that they are additive. This means that they build up an object layer by layer.

Before the printing starts, you need a 3D file of your design. This file of a three-dimensional object can be created in 3D modeling tools such as Blender, 123D Design, Rhino, SketchUp, etc. Once this file has been created, it can be sent to a 3D printer. If you do not own a printer or if you want a high-quality print with a choice of more than 100 different 3D printing materials, finishes, and color options, an online 3D printing service such as i.materialise is a smart choice.

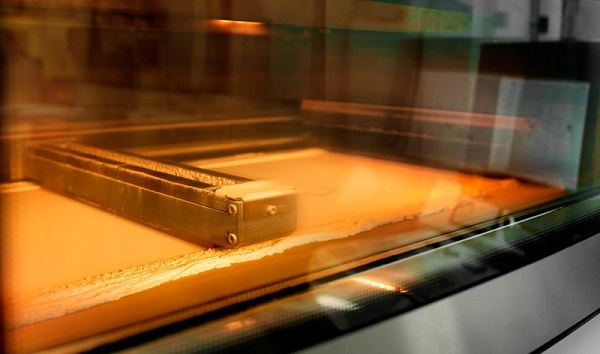

3D printers print your object layer by layer. The animation below demonstrates this process for Laser Sintering, a popular 3D printing technology.

However, there are several important 3D printing technologies that differ slightly from each other. Let’s take a look at how they work and what makes them so unique.

Laser Sintering

- This 3D printing technology spreads out a layer of fine powder.

- A laser beam heats up the areas that need to be sintered together.

- The parts that were touched by the laser are now fused together while the rest continues to remain loose powder.

- A new layer of fine powder is spread out. The next slice of your part is hardened and joined to the previous first.

- At the end your part is lifted out of the box of loose powder. It is then sandblasted and finished by hand.

- Learn more about Laser Sintering in this blog post.

Fused Deposition Modeling

- FDM printers use long plastic filaments.

- The nozzle moves to place one layer of the heated material at the correct locations.

- When a layer is drawn, the platform lowers by one layer thickness so the printer can start with the next layer.

- A second (dissolvable) filament is used for building support material.

- Learn more about Fused Deposition Modeling in this blog post.

Stereolithography

- The Stereolithography process takes place in a large tank and begins with a layer of liquid polymer spread over a platform.

- Since this piqued polymer is UV-sensitive, a UV laser hardens the area that will become one layer of your 3D print. The rest of the layer stays liquid.

- The platform is then lowered and the next layer is drawn directly on top of the previous one.

- When the object is complete, it is raised out of the tank via the supporting platform with the excess liquid flowing away.

- Learn more about Stereolithography in this blog post.

Direct Metal Laser Sintering (DMLS)

- A super-thin layer of Aluminum or Titanium powder is spread out by a roller.

- The print chamber of the 3D printer is then heated up but the powder does not melt yet since it has not reached its melting point.

- A laser touches the areas of the layer that are part of your design, raising the temperature of those areas just above the melting point.

- Learn more about Direct Metal Laser Sintering this blog post.

HP Multi Jet Fusion

- HP Multi Jet Fusion is a powder-based technology that does not use lasers.

- The powder bed is heated uniformly from the outset.

- A fusing agent is jetted where particles need to be selectively molten, while a detailing agent is jetted around the contours to improve part resolution.

- Lamps pass over the surface of the powder bed and the jetted material captures the heat and helps distribute it evenly.

Of course there are still more, related 3D printing technologies. For example, ‘Lost Wax Casting & 3D Printing’ is mainly used for creating jewelry items in gold, silver, brass, and bronze. To learn more about each and every one of our 18 different 3D printing materials, please visit our materials page.

If you have a 3D file that is ready to be printed, upload it here and let us take care of 3D printing and shipping your object.

Recommended Articles

No related posts.