Unboxing the Stratasys Fortus 900mc 3D printer

Thinking about printing on a Stratasys Fortus 900mc 3D printer? Now you can via our online 3D printing service. We just installed this 3000 kilo/660 lbs beast in at our headquarters. Check out our unboxing session of the Stratasys Fortus 900mc below.

It was a very exciting day: our newest 3D printer arrived and is now ready to take your orders. It is a Stratasys Fortus 900mc FDM 3D production system and we like it a lot. When people hear the term ‘3D printer’ they often think of desktop printers that can easily be bought online and delivered by post.

But the Stratasys Fortus 900mc is an industrial 3D printer – and a big one! Here is a simple guide to unboxing your Fortus 900mc.

Delivery of the Stratasys Fortus 900mc

Step 1. Open Truck. The blonde guy on the right, in the green tshirt is Robby, he manages the Materialise FDM center, the part of Materialise that 3D prints your ABS plastic designs for you.

Step 2. Remove crate & plastic covers.

Getting the Stratasys 3D printer ready for the crane

Step 3. Attach hooks to a crane.

Step 4. Lift out of the truck (also, never worry).

Installing the Fortus 900mc

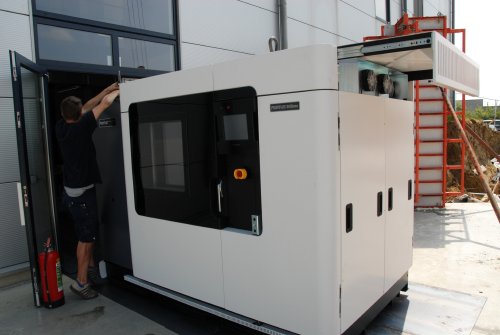

Step 5. Try to fit the Stratasys 3D printer through the door.

Step 6. Tow the Fortus 900mc into the building. Pro Tip: protect your floor.

Start printing on this giant beast

The Fortus is the largest FDM 3D printer in the world and joins its dozen smaller cousins in Materialise’s FDM Center.

- Weight approximately 3000 kilo/660 lbs

- Largest build envelope 914 x 610 x 914 mm/36 x 24 x 36 inch

- 2 build material and 2 support material bays for extended unattended builds

- Multiple layer thickness options 0.330 mm and 0.254 mm for faster throughput

0.178 mm for higher surface finish and feature detail

The Fortus 900mc will be used to print your parts in high-quality ABS plastic. When uploading your 3D model here, we might print it on this mighty machine. Learn more about our 3D printing materials here and about other industrial 3D printers that we use in this blog post.

Recommended Articles

No related posts.