The redesigned parts have arrived from the 3D printing service, and it’s time to begin dry-fitting them into sub-assemblies.

We explored some cost-saving by using two different 3D printing processes. While Multi-Jet Fusion (MJF) is often my preference, I opted for Selective Laser Sintering (SLS) for the RAM Scoop assembly. This particular SLS process uses a PA12 polyamide material, resulting in a standard white finish.

Upon inspection, the SLS parts appear to have slightly lower definition compared to MJF parts, though this could be an isolated instance.

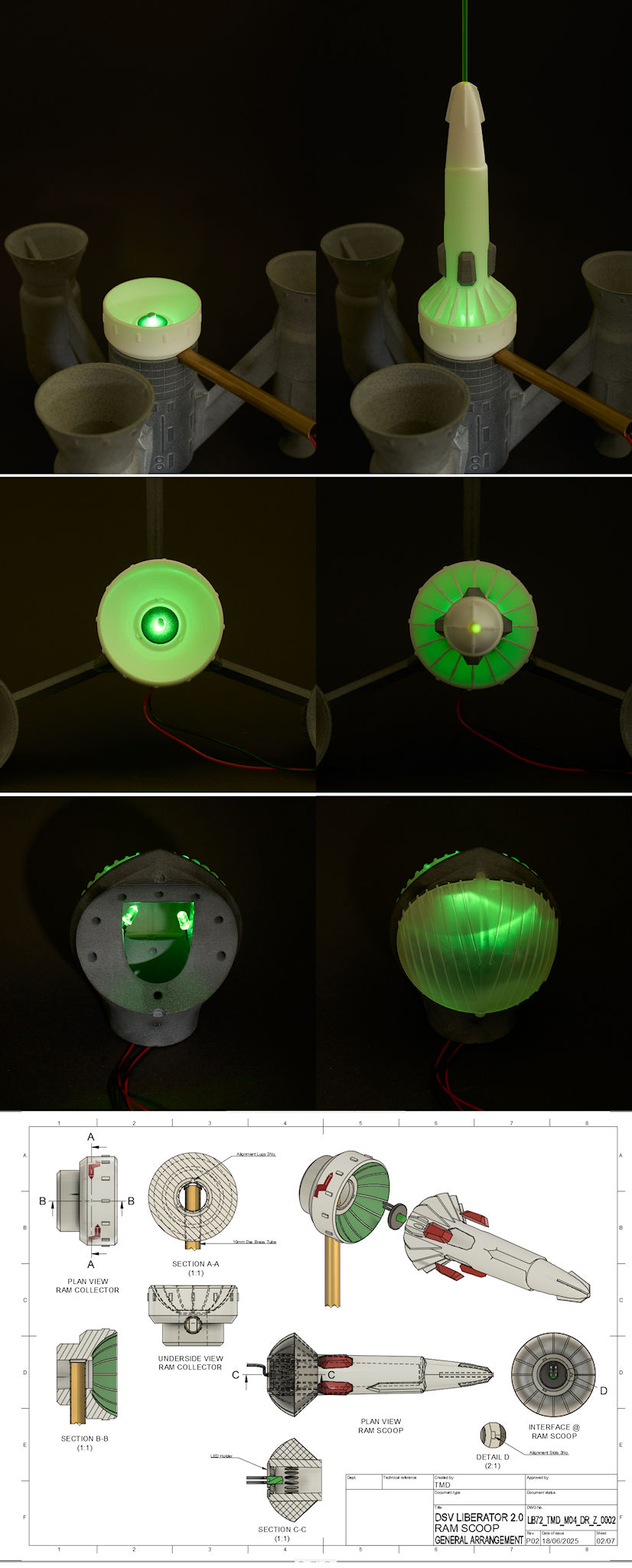

Encouragingly, all physical parts fit together precisely as anticipated in the digital prototype. A quick lighting test also revealed that the SLS material exhibits some light leaks, a characteristic not observed with MJF.

Overall, this prototyping phase has been quite successful. The key objectives of improving provisions for intricate painting, effective lighting, and ease of assembly have been met.

Original prototype assembled, painted and lit: