The 3D printed components have now been received from the i.Materialise 3D Printing service.

𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝗣𝗿𝗼𝗰𝗲𝘀𝘀 𝗮𝗻𝗱 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹:

The selected process was 𝗠𝘂𝗹𝘁𝗶-𝗝𝗲𝘁 𝗙𝘂𝘀𝗶𝗼𝗻 (𝗠𝗝𝗙), utilising a rubber-like material. This material is a 𝘁𝗵𝗲𝗿𝗺𝗼𝗽𝗹𝗮𝘀𝘁𝗶𝗰 𝗽𝗼𝗹𝘆𝘂𝗿𝗲𝘁𝗵𝗮𝗻𝗲 (𝗧𝗣𝗨), exhibiting excellent shock-absorbing capabilities and a 𝗦𝗵𝗼𝗿𝗲 𝗔 𝗛𝗮𝗿𝗱𝗻𝗲𝘀𝘀 𝗼𝗳 𝟵𝟬. Its tactile properties genuinely emulate rubber. Additionally, I had the parts dyed black to match the camera.

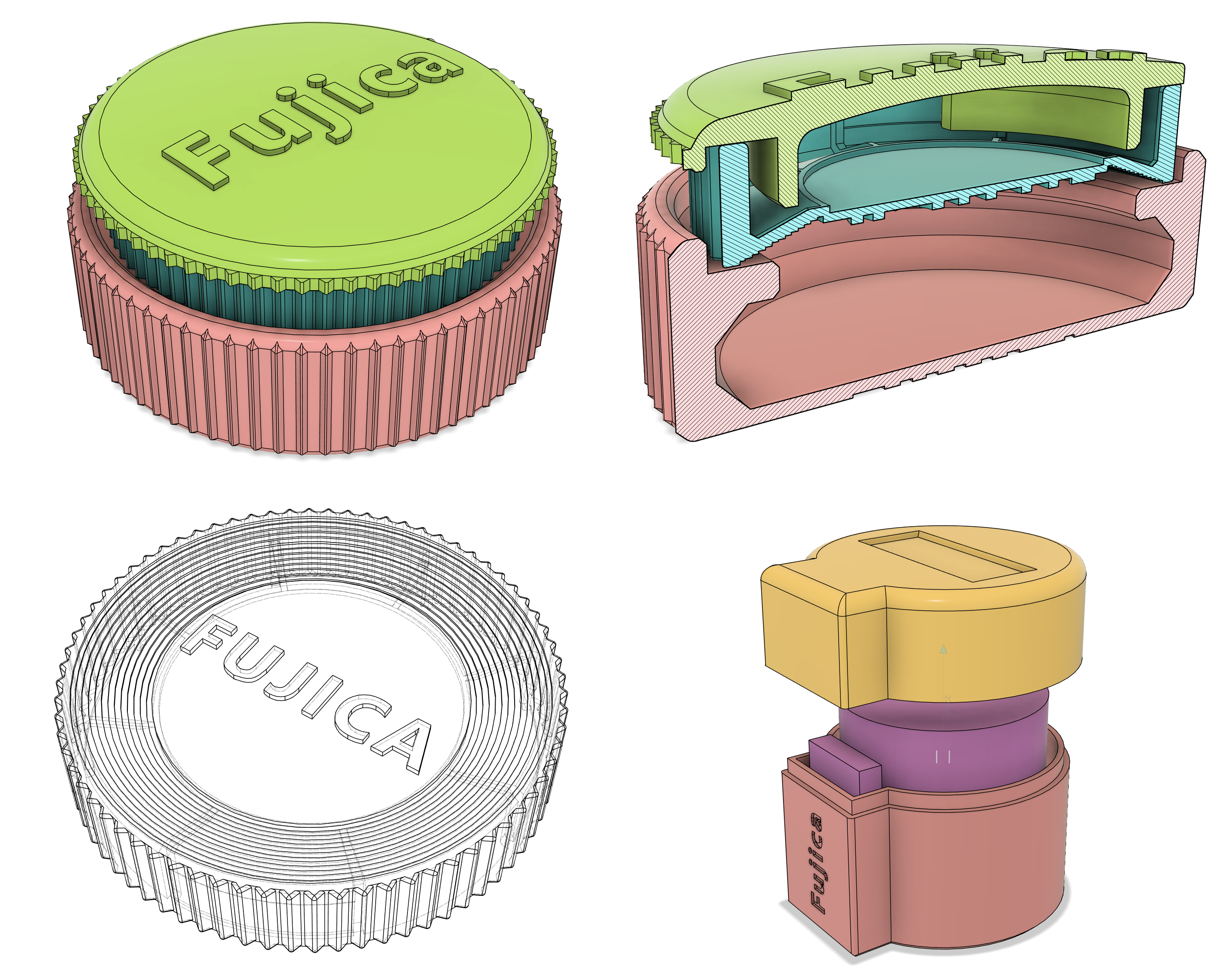

𝗙𝗶𝘁𝗺𝗲𝗻𝘁 𝗩𝗲𝗿𝗶𝗳𝗶𝗰𝗮𝘁𝗶𝗼𝗻 𝗼𝗻 𝗙𝘂𝗷𝗶𝗳𝗶𝗹𝗺 𝗙𝘂𝗷𝗶𝗰𝗮 𝗚𝗟-𝟲𝟵𝟬 𝗣𝗿𝗼𝗳𝗲𝘀𝘀𝗶𝗼𝗻𝗮𝗹 𝗥𝗮𝗻𝗴𝗲𝗳𝗶𝗻𝗱𝗲𝗿 (𝗰𝗶𝗿𝗰𝗮 𝟭𝟵𝟳𝟰):

• 𝗖𝗮𝗺𝗲𝗿𝗮 𝗕𝗼𝗱𝘆 𝗖𝗮𝗽: Achieved a perfect fit. This enables secure lens detachment for transit and safeguards the camera body from environmental ingress.

• 𝗙𝗿𝗼𝗻𝘁 𝗟𝗲𝗻𝘀 𝗖𝗮𝗽: Similarly, a perfect fit was observed.

• 𝗥𝗲𝗮𝗿 𝗟𝗲𝗻𝘀 𝗖𝗮𝗽: Initial fitment was excessively tight. This was attributed to either an overestimation of the material’s flexibility or a CAD design discrepancy. A successful remediation was performed by trimming approximately a 2mm wide strip from the opening using a scalpel, resulting in a satisfactory fit for both lens caps.

• 𝗩𝗶𝗲𝘄𝗳𝗶𝗻𝗱𝗲𝗿 𝗦𝘁𝗼𝗿𝗮𝗴𝗲 𝗕𝗼𝘅: This component achieved a perfect fit, with the lid demonstrating designed-in friction locking. This was the second iteration of the design. The first version, validated via paper templates, contained a fitting error. The improved second version benefited significantly from the integration of a digital mass model representing the viewfinder, which facilitated more effective clash conflict detection (see original LinkedIn post for images & animation of CAD model).

𝗥𝗲𝗶𝗻𝗳𝗼𝗿𝗰𝗲𝗱 𝗖𝗼𝗻𝗰𝗹𝘂𝘀𝗶𝗼𝗻 𝗼𝗻 𝗗𝗶𝗴𝗶𝘁𝗮𝗹 𝗣𝗿𝗼𝘁𝗼𝘁𝘆𝗽𝗶𝗻𝗴:

This practical exercise further substantiates the original conclusion: 𝟮𝗗 𝗗𝗿𝗮𝘄𝗶𝗻𝗴𝘀 (𝗮𝗻𝗱 𝗮𝘀𝘀𝗼𝗰𝗶𝗮𝘁𝗲𝗱 𝗽𝗵𝘆𝘀𝗶𝗰𝗮𝗹 𝘁𝗲𝗺𝗽𝗹𝗮𝘁𝗲𝘀) 𝗮𝗿𝗲 𝗮 𝘀𝘂𝗽𝗲𝗿𝗳𝗹𝘂𝗼𝘂𝘀 𝘀𝘁𝗮𝗴𝗲 𝗶𝗻 𝘁𝗵𝗲 𝗱𝗶𝗴𝗶𝘁𝗮𝗹 𝗽𝗿𝗼𝘁𝗼𝘁𝘆𝗽𝗶𝗻𝗴 𝘄𝗼𝗿𝗸𝗳𝗹𝗼𝘄. For scenarios involving high-volume additive manufacturing and stringent first-time fit requirements, future design initiatives would necessitate advanced reality capture techniques (e.g., laser scanning, photogrammetry, LIDAR) of the physical camera body and lenses.