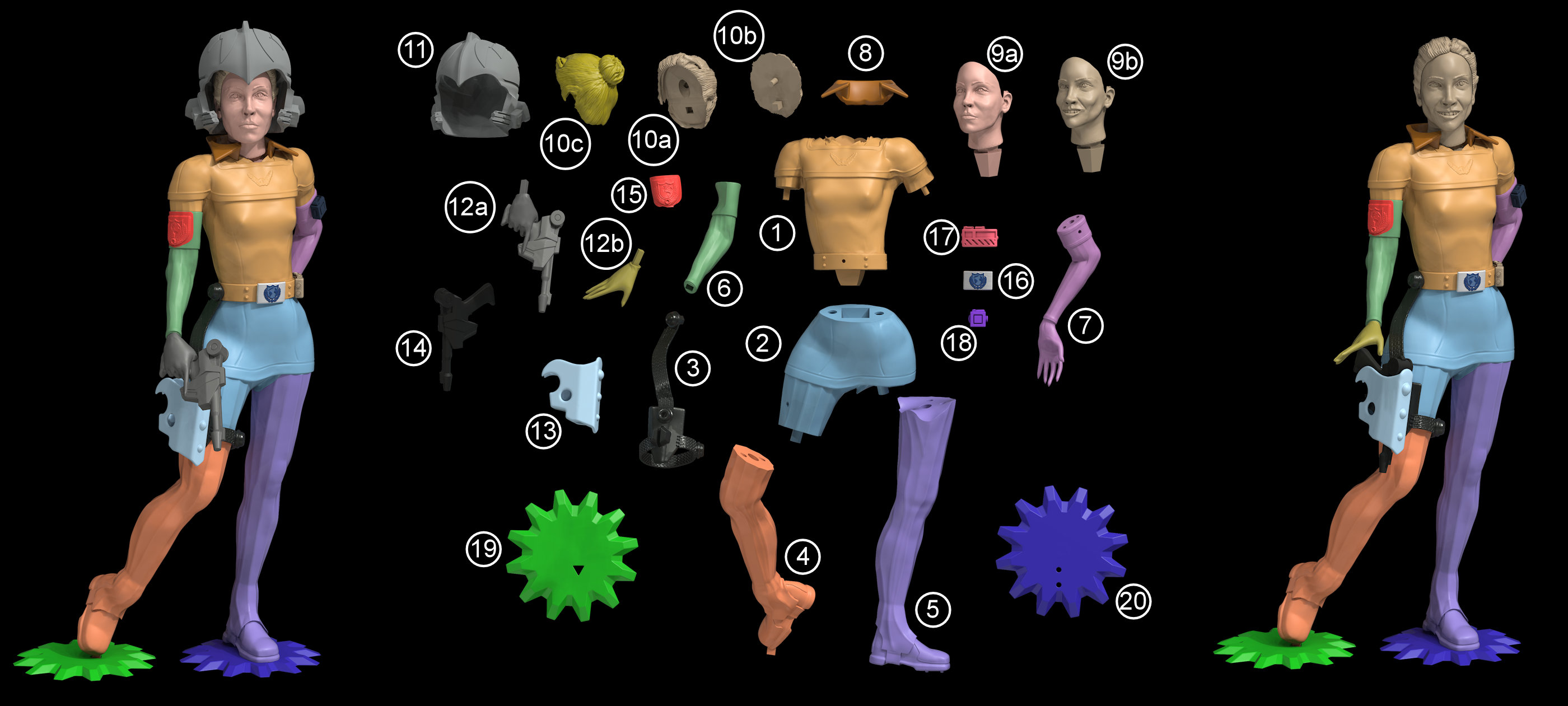

𝟯𝗗𝗖𝗼𝗮𝘁: 𝗪𝗶𝗹𝗺𝗮 𝟰.𝟬 𝗦𝗰𝘂𝗹𝗽𝘁𝗲𝗱 𝗣𝗮𝗿𝘁𝘀 - 𝗧𝗲𝘀𝘁 𝗙𝗶𝘁 𝗼𝗳 𝟯𝗗 𝗣𝗿𝗶𝗻𝘁𝘀

Just received the 3D printed prototype parts for Wilma 4.0, and I’m thrilled to share the results of the dry fitting!

𝗣𝗿𝗲𝗹𝗶𝗺𝗶𝗻𝗮𝗿𝘆 𝗖𝗵𝗲𝗰𝗸: 𝗗𝗿𝘆 𝗙𝗶𝘁𝘁𝗶𝗻𝗴 𝟯𝗗 𝗣𝗿𝗶𝗻𝘁𝗲𝗱 𝗣𝗮𝗿𝘁𝘀

I’m pleased to report that the parts fit as designed (see left photo), indicating no major rework on the joints is necessary. This success is attributed to both experience with the 3D printing process and careful design decisions during digital file preparation.

𝟯𝗗𝗖𝗼𝗮𝘁 𝗪𝗼𝗿𝗸𝗳𝗹𝗼𝘄 𝗩𝗮𝗹𝗶𝗱𝗮𝘁𝗶𝗼𝗻

This project marks the first time I’ve used 3DCoat for the entire workflow, from sculpting to 3D printing. My primary concern was potential dimensional errors during the conversion between Surface meshes and Voxel objects. To mitigate this, I incorporated larger fit tolerances. However, the physical prints confirm 3DCoat’s capability. Notably, the left arm widget, belt buckle, and belt holster achieved perfect friction fits.

𝗙𝗶𝗹𝗲 𝗦𝘂𝗯𝗺𝗶𝘀𝘀𝗶𝗼𝗻 𝗮𝗻𝗱 𝟯𝗗 𝗣𝗿𝗶𝗻𝘁 𝗣𝗿𝗼𝗰𝗲𝘀𝘀

File submission was seamless, thanks to a solid understanding of 3D print limitations and leveraging 3DCoat’s tools to address potential issues.

𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹 𝗮𝗻𝗱 𝗣𝗿𝗼𝗰𝗲𝘀𝘀: MJF (Multi-Jet Fusion additive manufacturing) with PA12 Polyamide

𝗣𝗿𝗼𝘀:

• No temporary support structures required.

• Higher density, lower porosity than SLS.

• Excellent strength.

• Neutral reaction with acrylic paints.

• Good machinability.

• +/- 0.3mm accuracy.

𝗖𝗼𝗻𝘀:

• Grainy surface texture, limiting fine detail painting.

• Visible striations, possibly requiring filler and sanding.

• Higher cost for low-volume production.

• Less favourable surface finish compared to resin-based printing post-painting.

𝗦𝗰𝗮𝗹𝗲 𝗮𝗻𝗱 𝗖𝗼𝘀𝘁 𝗖𝗼𝗻𝘀𝗶𝗱𝗲𝗿𝗮𝘁𝗶𝗼𝗻𝘀

The assembled model stands at approximately 450mm (1:4 scale). While this larger scale enhances handling and painting, it significantly increases prototyping costs compared to previous 1:6 to 1:8 scale projects.